13

Tubing

4.0 INSTALLATION

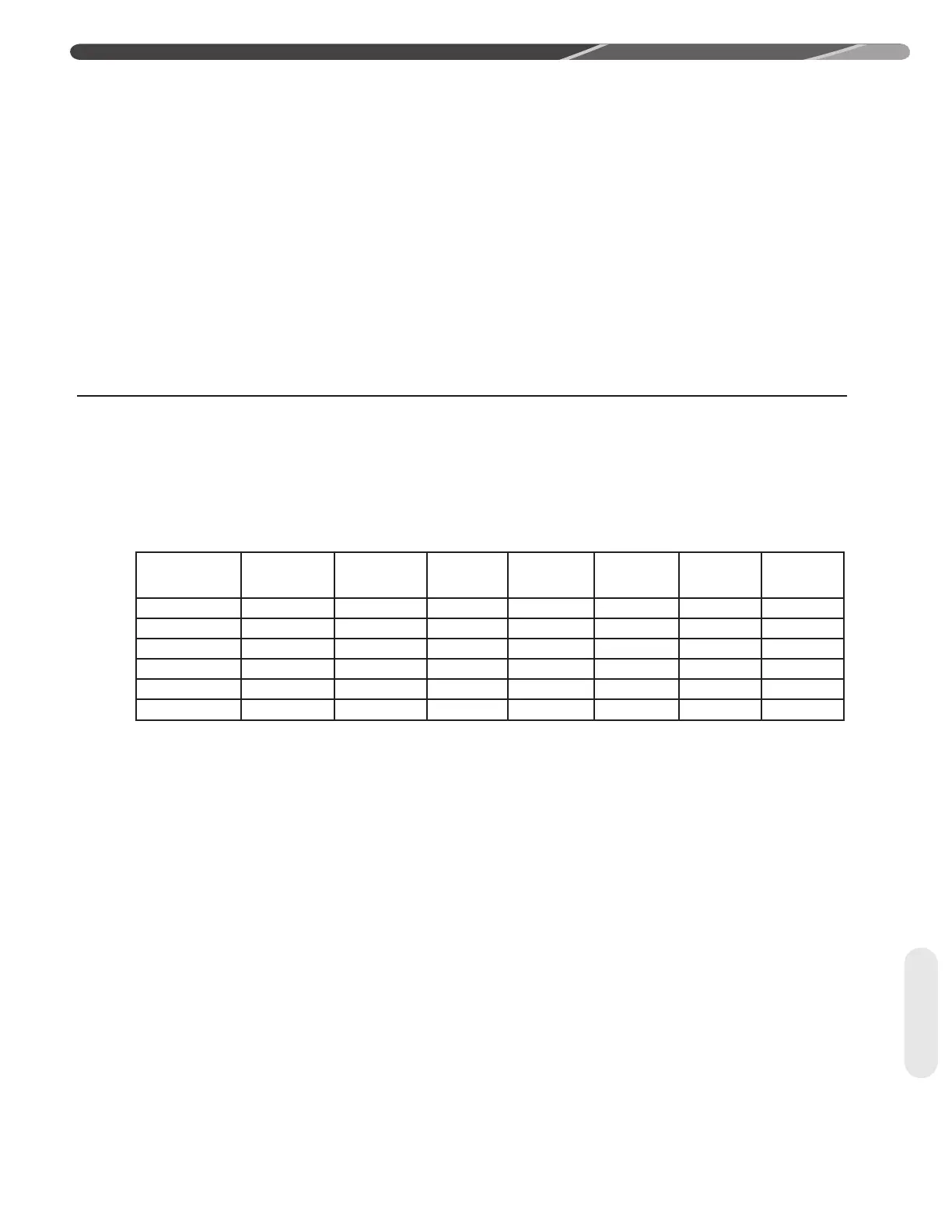

4.4.2.5 Capacity Losses

Long line lengths can result in a reduction in capacity

due to vapor line pressure drop and heat gain or loss.

Refer to Table 2 for capacity loss multipliers for various

vapor line diameters and equipment line lengths. This

table does not account for any capacity loss due to heat

gain or loss from the environment. It is extremely im-

portant not to oversize the vapor line to minimize capac-

ity loss at the expense of proper oil return. If the table

shows an “NR” for a particular vapor line diameter and

length, or, if a vapor line diameter is not listed, oil return

will not be adequate.

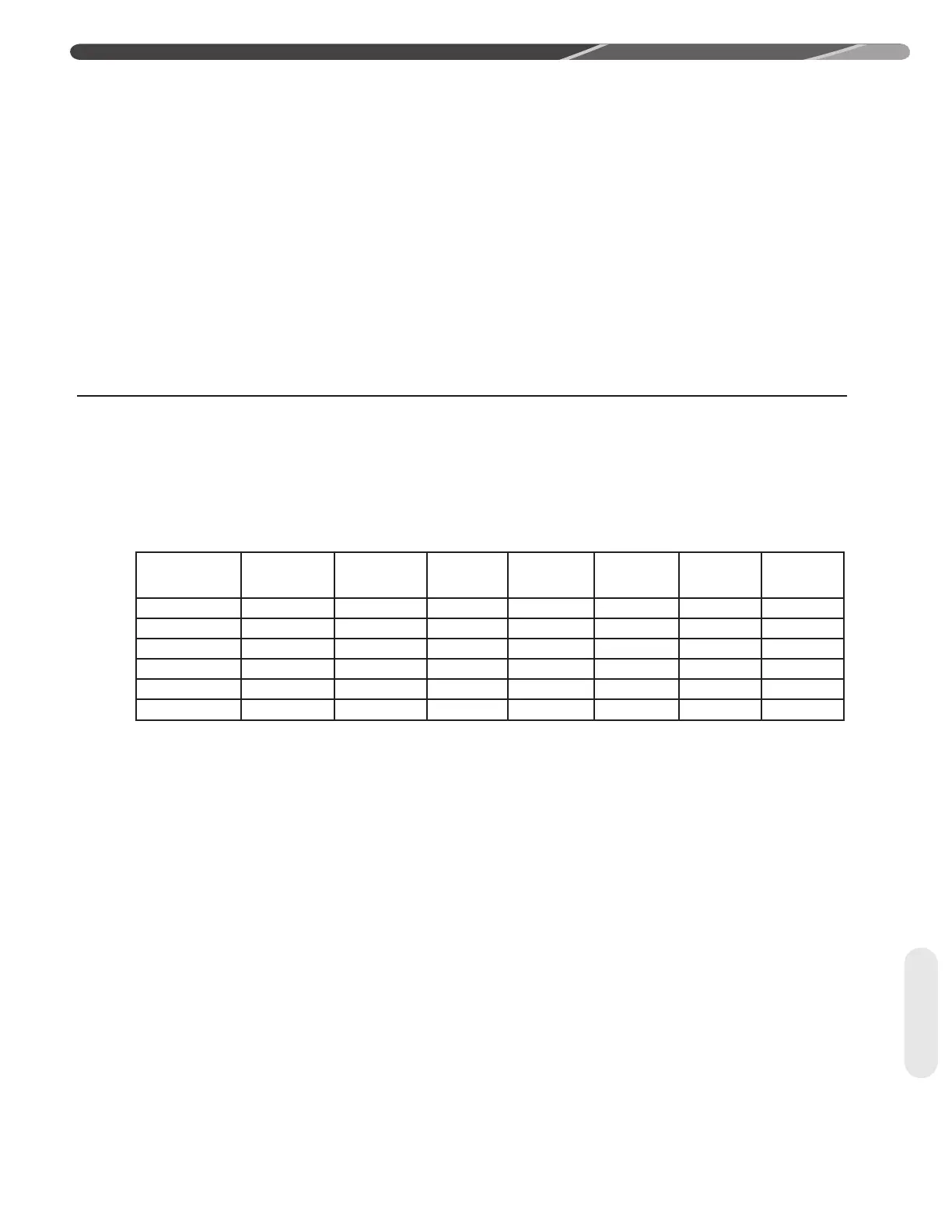

Table 1

Refrigerant tubing is measured in terms of actual length

and equivalent length. Actual length is used for refrig-

erant charge applications. Equivalent length takes into

account pressure losses from tubing length, ttings, ver-

tical separation, accessories, and lter driers. The table

below references different commonly used equivalent

lengths.

4.4.3 Line Set Length and Fitting Losses

Line Size

in [mm]

90° Short

Radius

Elbow

90° Long

Radius

Elbow

45°

Elbow

Solenoid

Valve

Check

Valve

Sight

Glass

Filter

Drier

3/8 [9.53] 1.3 [0.40] 0.8 [0.24] 0.3 [0.09] 6 [1.83] 4 [1.22] 0.4 [0.12] 6 [1.83]

1/2 [12.71] 1.4 [0.43] 0.9 [0.27] 0.4 [0.12] 9 [2.74] 5 [1.52] 0.6 [0.18] 6 [1.83]

5/8 [15.88] 1.5 [0.46] 1 [0.30] 0.5 [0.15] 12 [3.66] 6 [1.83] 0.8 [0.24] 6 [1.83]

3/4 [19.05] 1.9 [0.58] 1.3 [0.40] 0.6 [0.18] 14 [4.27] 7 [2.13] 0.9 [0.27] 6 [1.83]

7/8 [22.23] 2.3 [0.70] 1.5 [0.46] 0.7 [0.21] 15 [4.57] 8 [2.44] 1 [0.30] 6 [1.83]

1-1/8 [28.58] 2.7 [0.82] 1.8 [0.55] 0.9 [0.27] 22 [6.71] 12 [3.66] 1.5 [0.46] 6 [1.83]

Loading...

Loading...