English

10

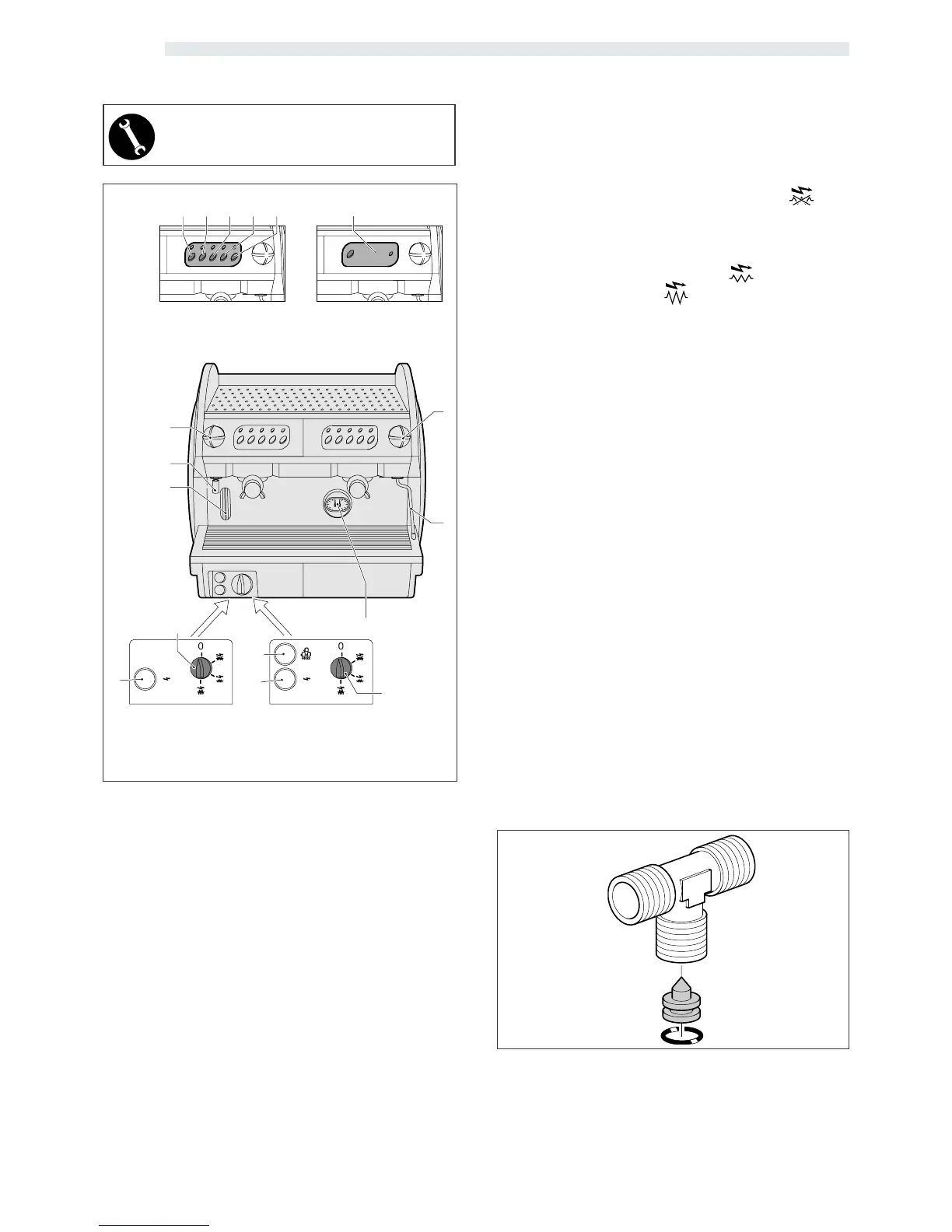

6.1 Long coffee gigleur

The machine is fitted with a gigleur ( 1 per unit) with a

clearance of 0.6 mm (Cod. WGA26G0074/01).

For greater coffee delivery speed, in the case of long coffees,

no.2 gigleurs are also included with the machine (complete

with seals) with a clearance of 0.8 mm (Cod.

WGA26G0073/01). The gigleur is located in the

exchanger supply fitting (1 per group).

6 - START UP

Once the water and electrical connections have been made,

proceed to start up the machine.

Open the mains water supply tap (A) (fig 2).

Close the protection switch (C) (fig 2).

Position the machine main switch (9) to position the

machine on indicator will come on (7).

The auto-levelling device will come into operation so that

the water reaches a normal level in the boiler (5).

Position the main switch (9) to position for operation at

normal power or to position for operation at full power,

thereby powering the resistances.

Wait for the pressure to reach its operational pressure

1.1÷1.3 atm checking the boiler pressure on the gauge

(6).

Should the machine fail to stabilize on the indicated values

it is necessary to calibrate the pressure switch as described

in paragraph 6.2.

Then check the pressure on the pump gauge (6) putting a

unit into operation with filter holder engaged filled with

ground, dosed and pressed coffee in order to achieve an

effective working pressure of 8/9 atm.

Should re-calibration of the pump pressure be necessary

this operation should be undertaken as indicated in

paragraph 6.3.

The machine is now ready for use.

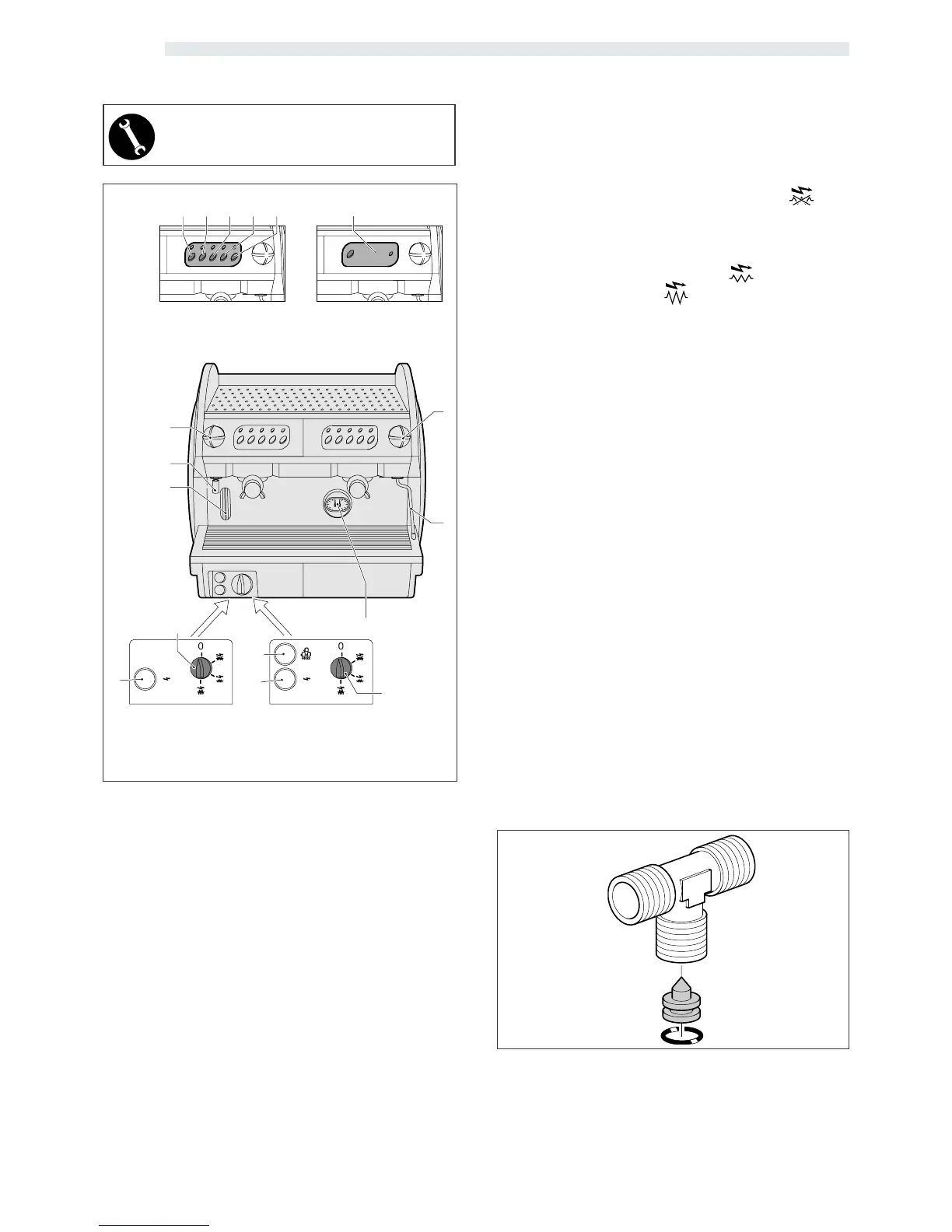

fig. 3

1 Steam tap

2 Steam dispenser nozzle

3 Hot water tap

4 Hot water dispenser

5 Boiler level indicator

6 Two boilers/pump manometer

7 Coffee maker ON LED

8 Cup warmer ON/OFF switch

9 Power ON/OFF switch

10 Selection: 1 espresso coffee

11 Selection: 2 espresso coffees

12 Selection: 1 weak coffee

13 Selection: 2 weak coffees

14 Dispense/Stop button

15 Control coffee switch (SM)

15

3

3

4

6

2

1

mod. SE

10 11 12 13 14

15

mod.

SM

8

7

9

5

7

9

fig. 4

Loading...

Loading...