Leatherwork

®

Guidebook | 2827 | Sailrite�com

Troubleshooting the Leatherwork

UsethisnextsectionasaguidetobetterunderstandyourLeatherworkandtohelpne-

tune and resolve common sewing machine problems�

A

33

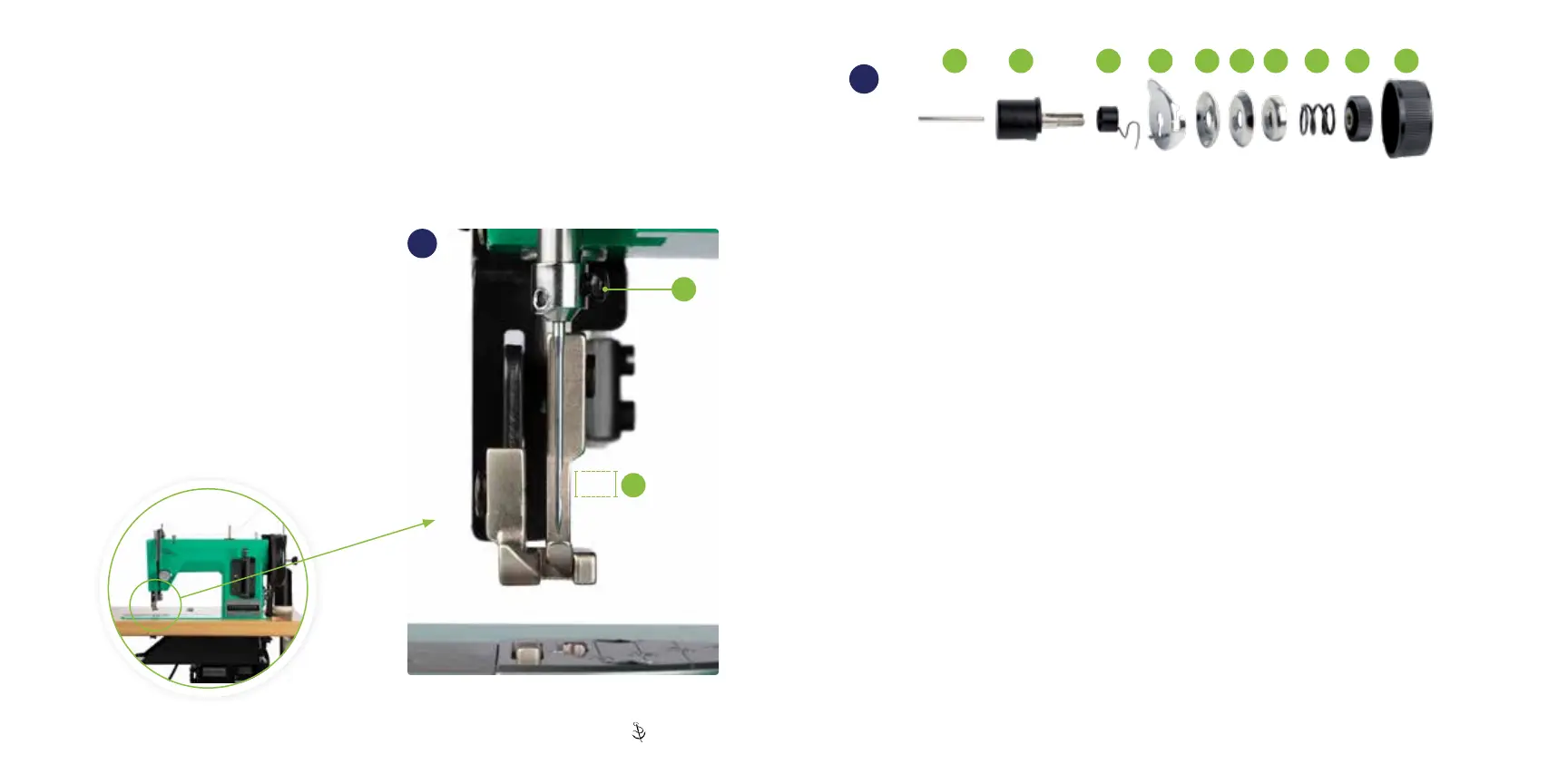

Replacing Take-Up Spring

If you are getting inconsistent stitch tension or if your thread looks loose and sloppy near the tension

assembly under operation, check your take-up spring (J).Ifthewirehookhasbrokenoff,you’llneed

to replace the take-up spring� To do this, disassemble the Upper Tension Assembly� Keep track of

how the parts are removed as they will be replaced in the same manner (34)�

1� Pull the cover knob (C) straight off (wiggle a

bit if needed)�

2� Unscrew and remove the threaded

knob (D)�

3� Remove the big spring (E), the spring

holder (F), the two tension disks (G and H),

and the keyway washer with pip (I)�

4� Remove the old take-up spring (J) by

pulling it straight out�

5� Slide the new take-up spring over the core

post (K) so that the pip on the back faces

in toward the machine and the straight arm

of the spring faces down (approximately at

a6o’clockposition).Pushthespringinall

the way�

6� Spin the arm of the spring clockwise past

the slot in the plastic core�

7� While holding the spring arm in place, slide

the keyway washer (I) back onto the core

with the pip facing in, so the take-up spring

arm rests on the metal pip of the washer�

8� Replacethersttensiondisk(H) with the

convex side facing out� Add the second

tension disk (G) with the concave side

facing out�

9� Replace the spring holder (F) with the

concave side facing out and the spring (E)�

Screw the threaded knob (D) back on the

post and add the cover knob (C)�

34

L K J I H G F E D C

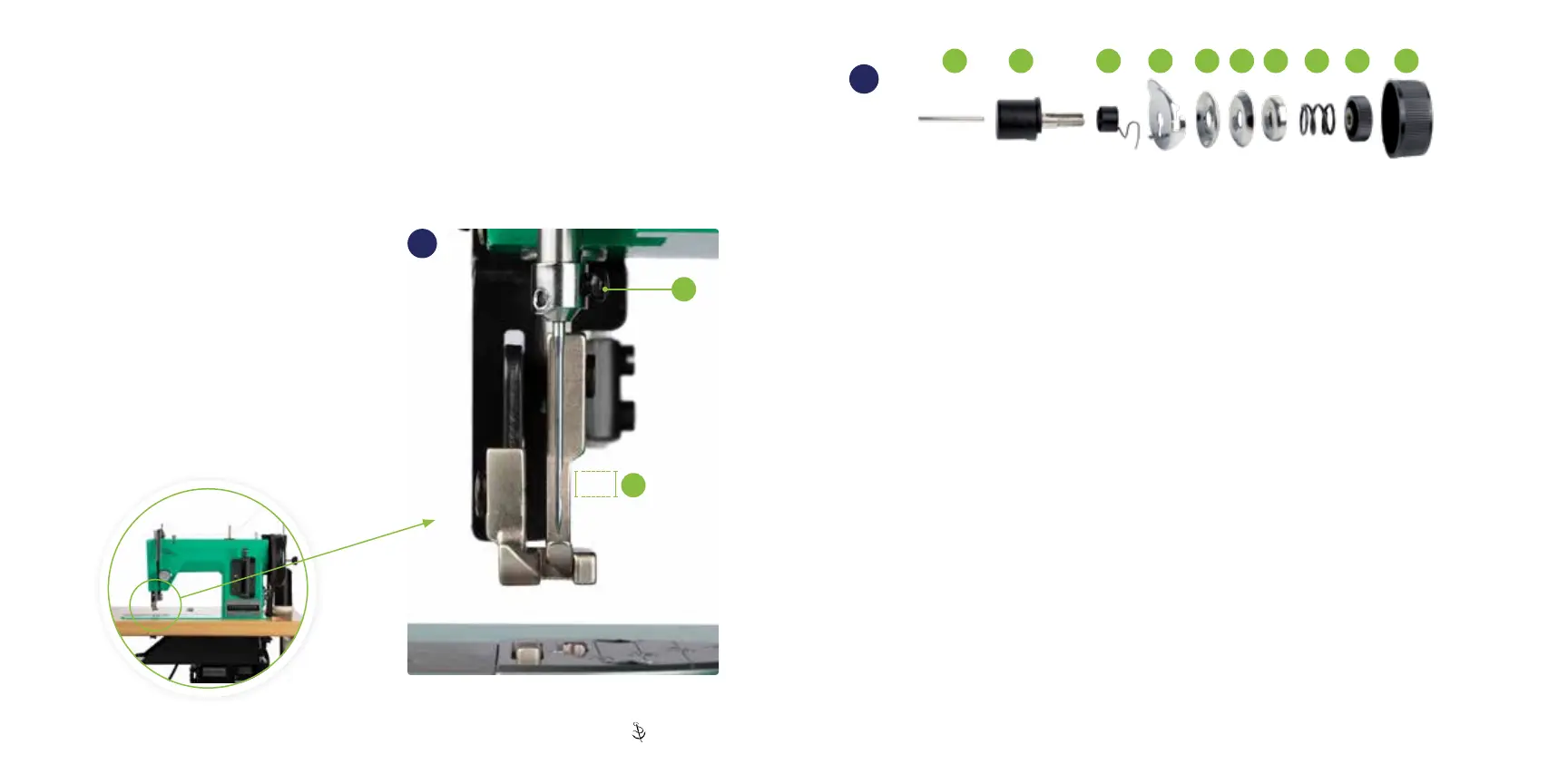

Proper Needle Orientation

& Installation

When installing a new needle, make sure the

needle is inserted in the correct direction� With

the front of the machine facing you, the scarf or

carved-out area (A) of the needle should face to

the right� Push the needle all the way up into the

needle bar, then tighten the needle screw (B)�

B

Loading...

Loading...