41 | Sailrite�com Leatherwork

®

Guidebook | 42

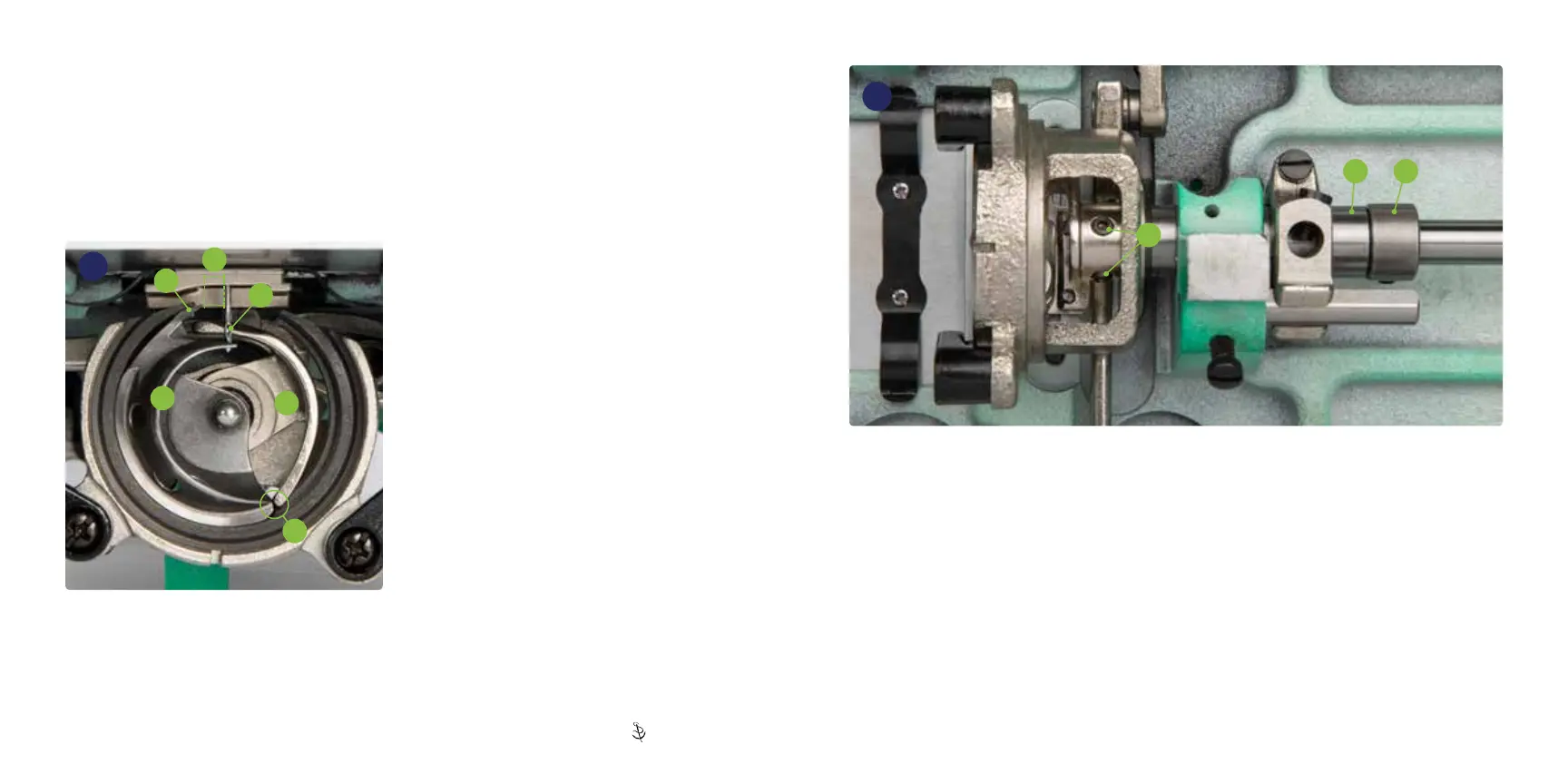

Check the Rotational Timing of the Shuttle Gib Hook

The Shuttle Gib Hook (A) is driven by the Shuttle

Driver (B)� To change the rotation of the hook,

the driver must be repositioned�

1� Turn the balance wheel so the gib

hook point (C) is at its furthest position

counterclockwise (47)�

2� Useyourngertopushthegibhook

counterclockwise to remove any gap at (D)�

3� Measure the distance between the gib

hook point (C) and the needle (E)� The

driver is correctly positioned when the

point is between 1/8 inch and 3/16 inch

counterclockwise of the needle (F)�

If spaced properly, the driver is set correctly�

If not, continue to adjust the driver (p� 42)�

Hook/Driver Gap

Oscillating hook sewing machines have loose tolerances between the Shuttle Gib Hook and the Shuttle

Driver� This play between the parts is intentional and allows the Leatherwork to sew a wide variety of

thread sizes� The typical play between parts is 0�04 inch�

47

B

A

F

C

E

D

48

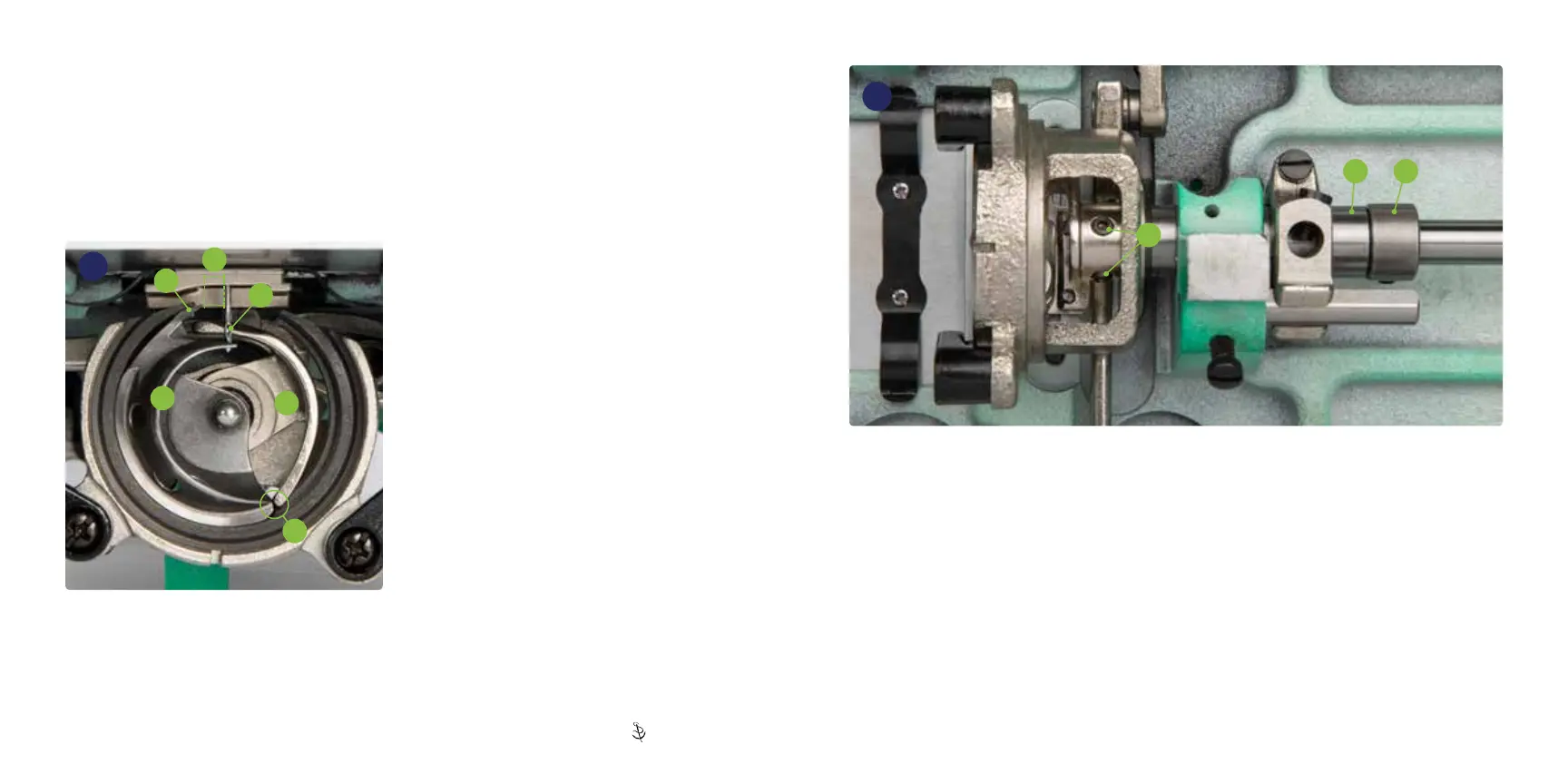

Adjust the Driver

4� The driver is secured to the lower shaft with two set screws (G)� Loosen the screws and gently

twist the Shuttle Driver to match (47, F).Ifthettotheshaftistight,carefullyuseascrewdriver

as leverage� Do not allow the driver to move to the left, which would be evident by any play

between H and I� Once proper position is found and there is no play between H and I, retighten

the two set screws (G)

After adjusting the driver, check the left-right positioning of the Shuttle Gib Hook (p� 43)�

G

H I

Loading...

Loading...