12 | EN STOUCH v2019.1

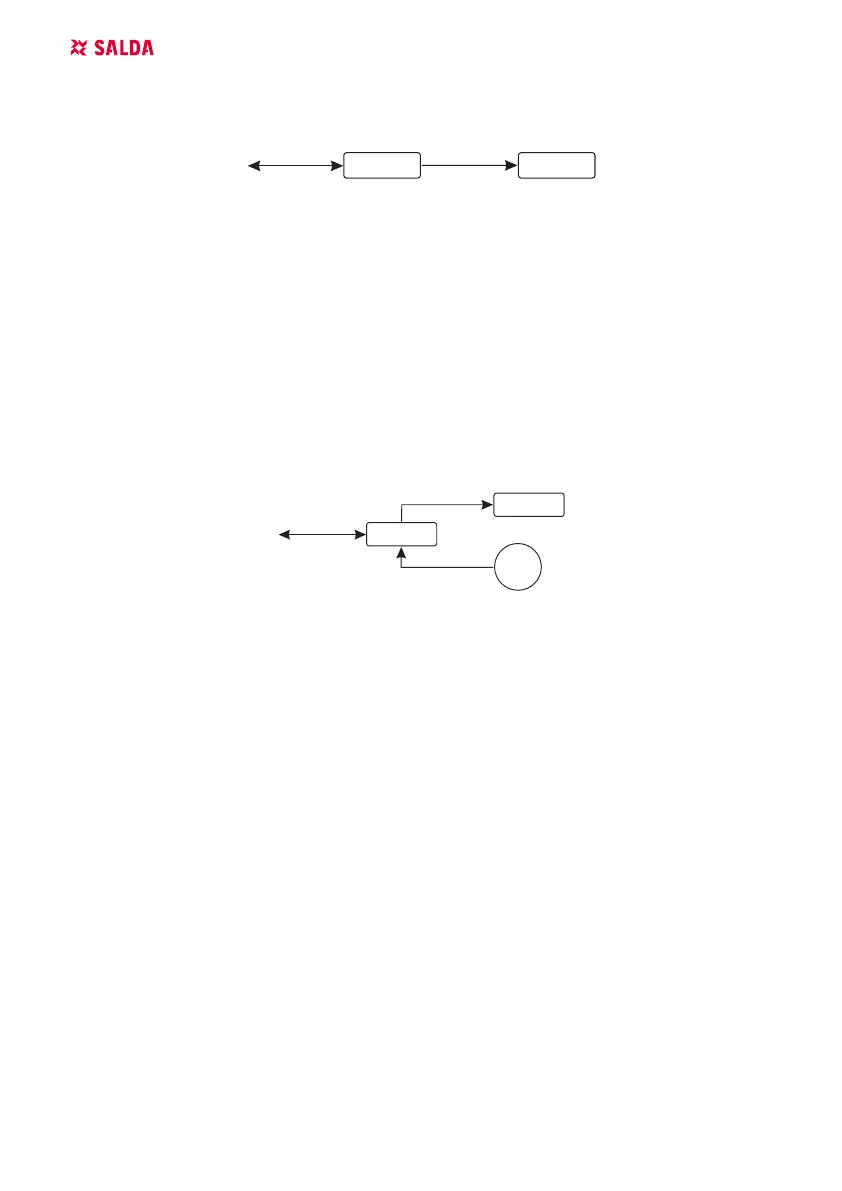

12.3. FAN CONTROL WHEN SPEED IS SET USING CONTROLLER AND/

OR COMPUTER VIA MODBUS

0...10 VDC

RC

FAN

MODBUS

0...10 VDC

RC

FAN

MODBUS

0...10 VDC

PS

0...10 VDC

RC

FAN

0...10 VDC

PS

MODBUS

AHU

MODBUS

RC

AHU

RC

AHU

BMS

RC - controller (master); FAN - fan

Using this remote controller and CO

2

transmitter it is possible to reduce inside carbon dioxide level.

This controller allows controlling both device and 0..10 VDC fan. In service menu, select desired

speed control method (F.01). If control based on preset speeds is selected, then select them in menu

items F.03, F.04, F.05, F.06.

NOTE: The air quality converters and remote controller (when fan is controlled) must be powered

from a separate power source. It is not supplied with the remote.

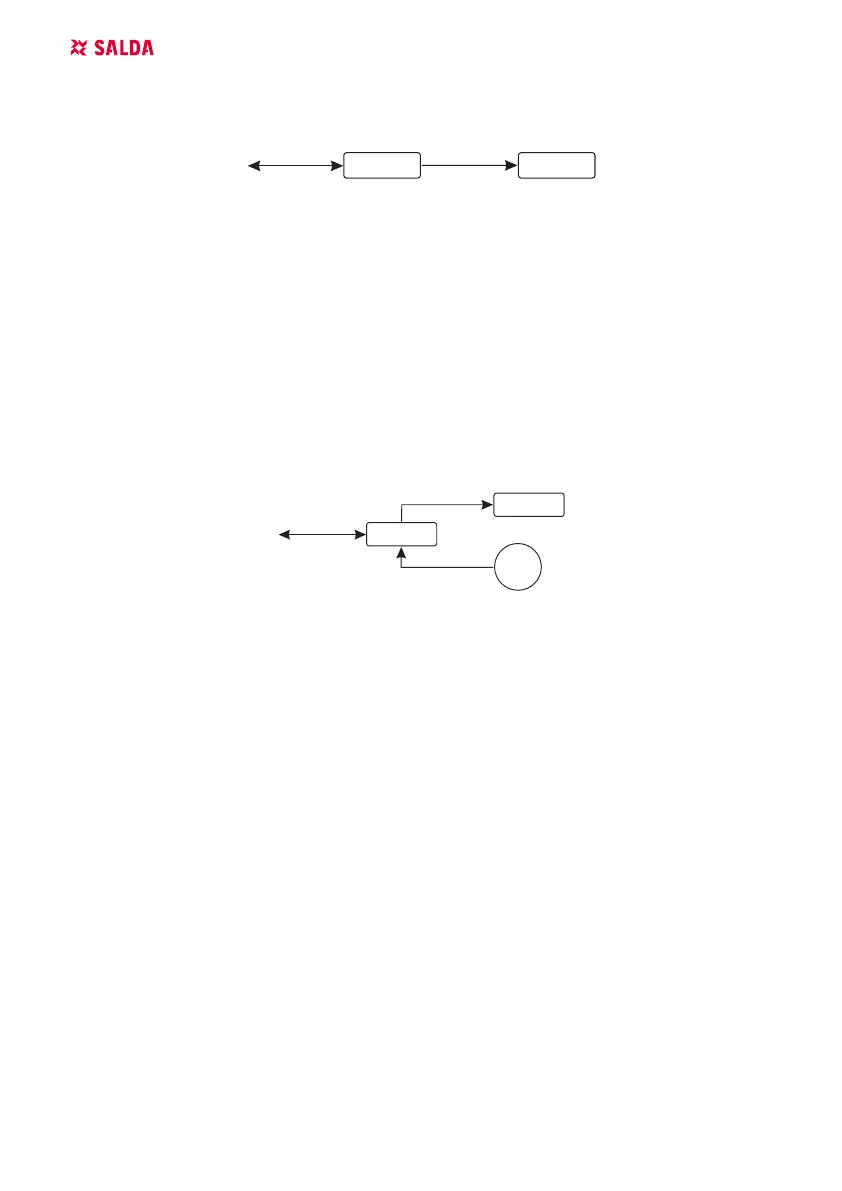

12.4. PRESSURE CONTROL WHEN SELECTED USING CONTROLLER

AND/OR COMPUTER VIA MODBUS

MODBUS

RC

AHU

0...10 VDC

RC

FAN

MODBUS

0...10 VDC

RC

FAN

MODBUS

0...10 VDC

PS

0...10 VDC

RC

FAN

0...10 VDC

PS

MODBUS

AHU

MODBUS

RC

AHU

RC

AHU

BMS

RC - controller (master); PS - pressure sensor; FAN - fan

Desired pressure can be maintained by connecting 0..10 VDC fan and 0..10 VDC pressure convert-

er directly to the controller. Control and pressure sensor parameters can be changed in controller.

When controller is used as Modbus slave device (air handling unit is not controlled by this principle),

it allows controlling all parameters and monitoring of pressure sensor readings.

For pressure based control, select the following parameters in the service menu:

F.01 - 2

F.14 - 1

F.15 and F.16 - based on pressure converter parameters

F.11, F.12 and F.13 - (PID control ratios). If pressure is maintained incorrectly, these parameters

can be adjusted.

F.0 - F.10 - seting of xed speeds (supports dierent pressure level in Pa)

F.43 -1 - 0..10VDC output activated.

Loading...

Loading...