ENGLISH

16

7. INSTALLATION AND ELECTRICAL CONNECTION

DANGER! Risk of fatal injury!

Inappropriate installation or electrical connection can

be life-threatening.

•The installation and electrical connection may only be

carried out by qualified personnel in accordance with

the applicable regulations!

•Observe the regulations for accident prevention.

7.1 Installation

Install the switchgear in a dry, vibration-free and frost-safe

location.

Protect the place of installation from direct sunlight.

Borehole distances 268 x 188 mm (WxH). For more information,

see also bottom side of switchgear. For fastening, provide

screws (4 screws, Ø max 4 mm) and the corresponding dowels.

To fasten the switchgear, open the upper part of the housing:

•Loosen the 4 cover fixing screws

•Fasten the switchgear to the wall with the dowels and screws.

7.2 Electrical connection

DANGER! Risk of fatal injury!

Improper electrical connections can lead to fatal elec-

trical shocks.

Only allow the electrical connection to be made by an

electrician approved by the local electricity supply

company and in accordance with the local regulations

in force.

•The type of mains, current and voltage of the mains connec-

tion must match the details on the type plate of the pump/

motor.

•Mains requirements:

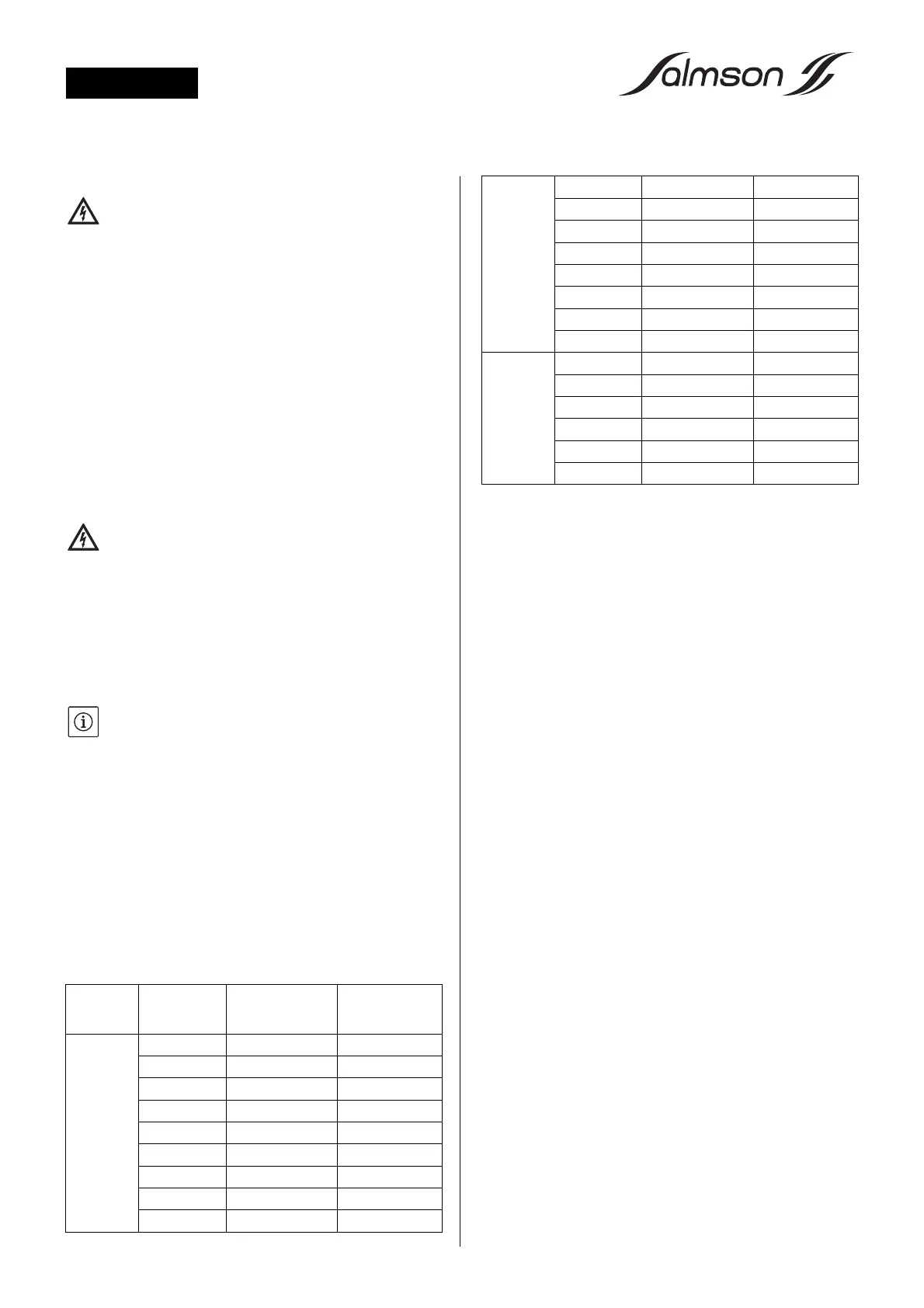

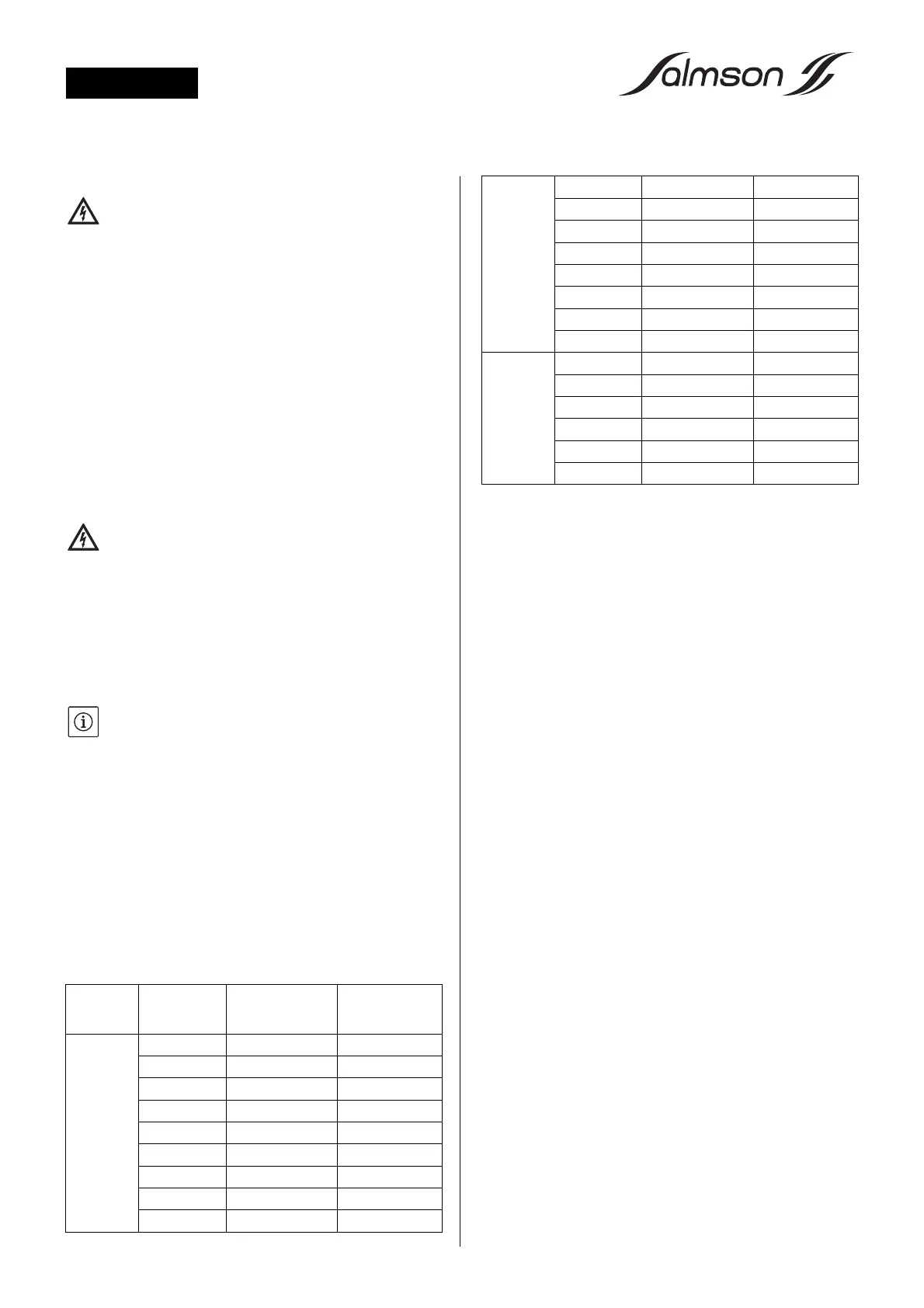

NOTE: In accordance with DIN EN/IEC 61000-3-11 (see

table below), the switchgear and pump with motor

power of ... kW (column 1) are provided for operation

on a mains power supply with a system impedance of

Z

max

at the house connection of max. ... Ohm (column

2) for a maximum number of ... switchings (column 3).

If the mains impedance and the number of switching

operations per hour is greater than the values given in

the table, because of the unfavourable mains connec-

tions, the switchgear with the pump may lead to tem-

porary voltage drops and also to disturbing voltage

fluctuations, or flickering.

Therefore, measures may be necessary before the

switchgear with pump can be operated correctly on

this connection. The necessary information must be

obtained from the local electricity supply company

and the manufacturer.

•Mains side fuse protection:

– max. 16 A, slow-blow (with premounted cable 1.5 mm² for

1~)

– max. 25 A, slow-blow (with direct power supply to terminal)

•To increase operating safety, it is essential that a circuit breaker

(which disconnects all power leads) with K characteristic is

used. Provide residual-current-operated protection switch in

accordance with the regulations in force.

•Feed the ends of the pump cable through the cable screw fit-

tings and cable inlets and wire them according to the mar-

kings on the terminal strip.

•Earth the pump/installation according to regulations.

•The terminal strip is to be connected as follows:

Mains connection 1~230 V (L, N, PE):

Terminals 2/T1, N, PE

Connection to the main switch at the terminals 2/T1 and N

according to the wiring diagram (Fig. 2). The grounding con-

ductor is connected to the remaining PE terminal.

Mains connection 3~400 V (L1, L2, L3, PE):

Terminals 2/T1, 4/T2, 6/T3, PE

Connection to the main switch at the terminals 2/T1, 4/T2 and

6/T3 according to the wiring diagram (Fig. 2). The grounding

conductor is connected to the remaining PE terminal.

Motor contactor (terminals 2/T1, 4/T2, 6/T3)

The pumps are connected directly to the motor contactor at

the terminals 2/T1, 4/T2 and 6/T3 according to the wiring dia-

gram (Fig. 2). The grounding conductor is connected to the

remaining PE terminal.

SSM (terminals 11, 12, 13):

Connection for external collective fault signal, potential-free

changeover contact,

•min. contact load 12 V DC, 10 mA,

•max. contact load 250 V~, 1A,

e.g. for connecting a horn, flashing light or alarm switchgear

(at potential-free input).

The contact is closed between terminals 12 and 13 in the event

of an alarm, when the voltage fails, or when the main switch is

switched off.

Output [kW]

(column 1)

System

impedance [Ω]

(column 2)

Switchings per

hour

(column 3)

3~400 V 2.2 0.2788 6

2-pole 3.0 0.2000 6

4.0 0.1559 6

2.2 0.2126 24

3.0 0.1292 24

4.0 0.0889 24

2.2 0.1915 30

3.0 0.1164 30

4.0 0.0801 30

3~400 V 3.0 0.2090 6

4-pole 4.0 0.1480 6

2.2 0.2330 24

3.0 0.1380 24

4.0 0.0830 24

2.2 0.2100 30

3.0 0.1240 30

4.0 0.0740 30

1~230 V 1.5 0.4180 6

2-pole 2.2 0.2790 6

1.5 0.3020 24

2.2 0.1650 24

1.5 0.2720 30

2.2 0.1480 30

Loading...

Loading...