22

Installation Procedure

English

Installation Procedure

026/035

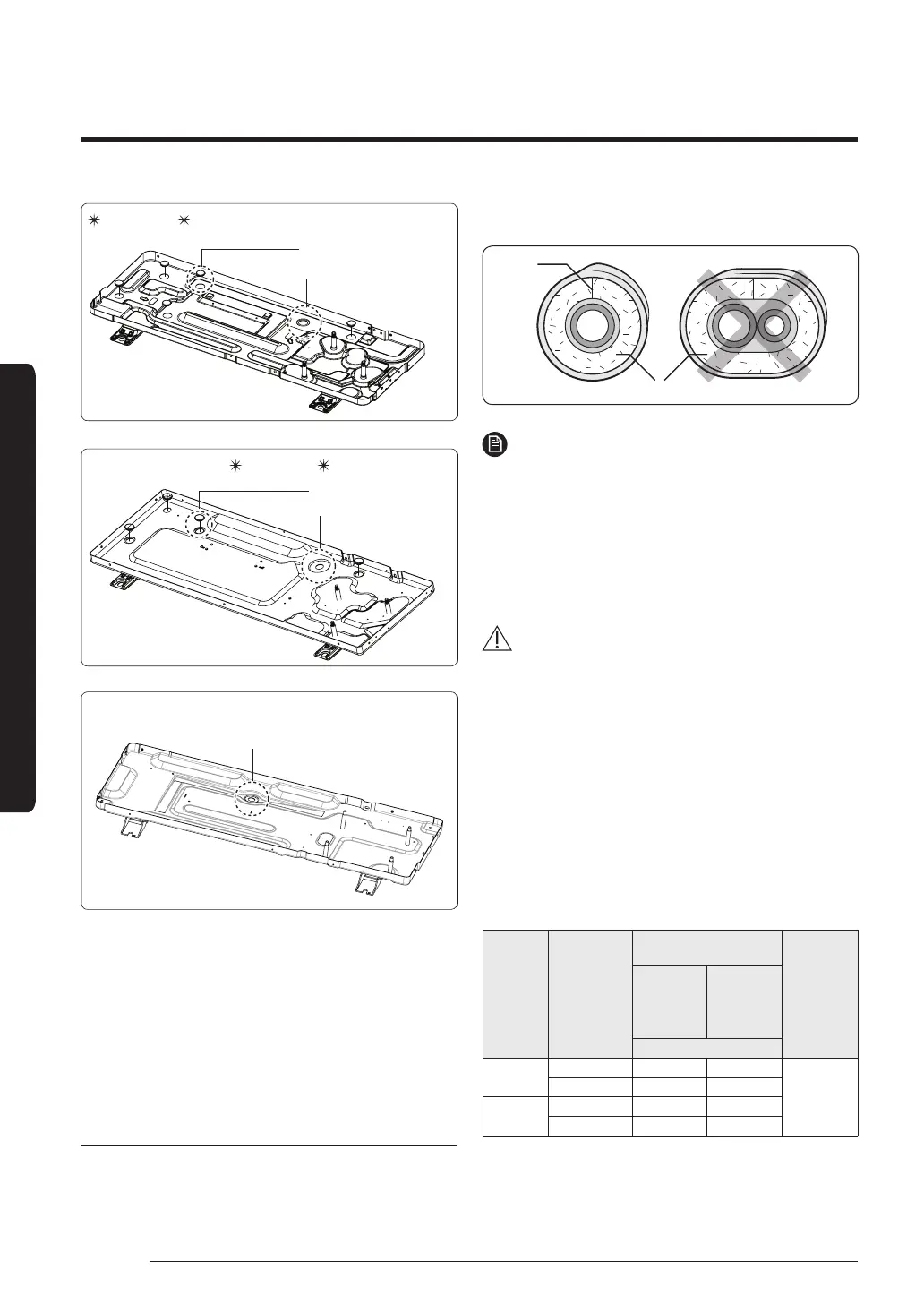

Drain cap (5EA)

Drain plug (1EA)

/AC052MXASEH

060/071

Drain cap (4EA)

Drain plug (1EA)

AC052MXADKH/

AC100MXASEH

Drain plug (1EA)

• When installing the product, make sure that the

rack is not placed under the drain hole.

• If the product is installed in a region of heavy

snow, allow enough separation distance between

the product and the ground.

Step 12 Insulating the refrigerant

pipes

Once you have checked that there are no leaks in the

system, you can insulate the piping and hose.

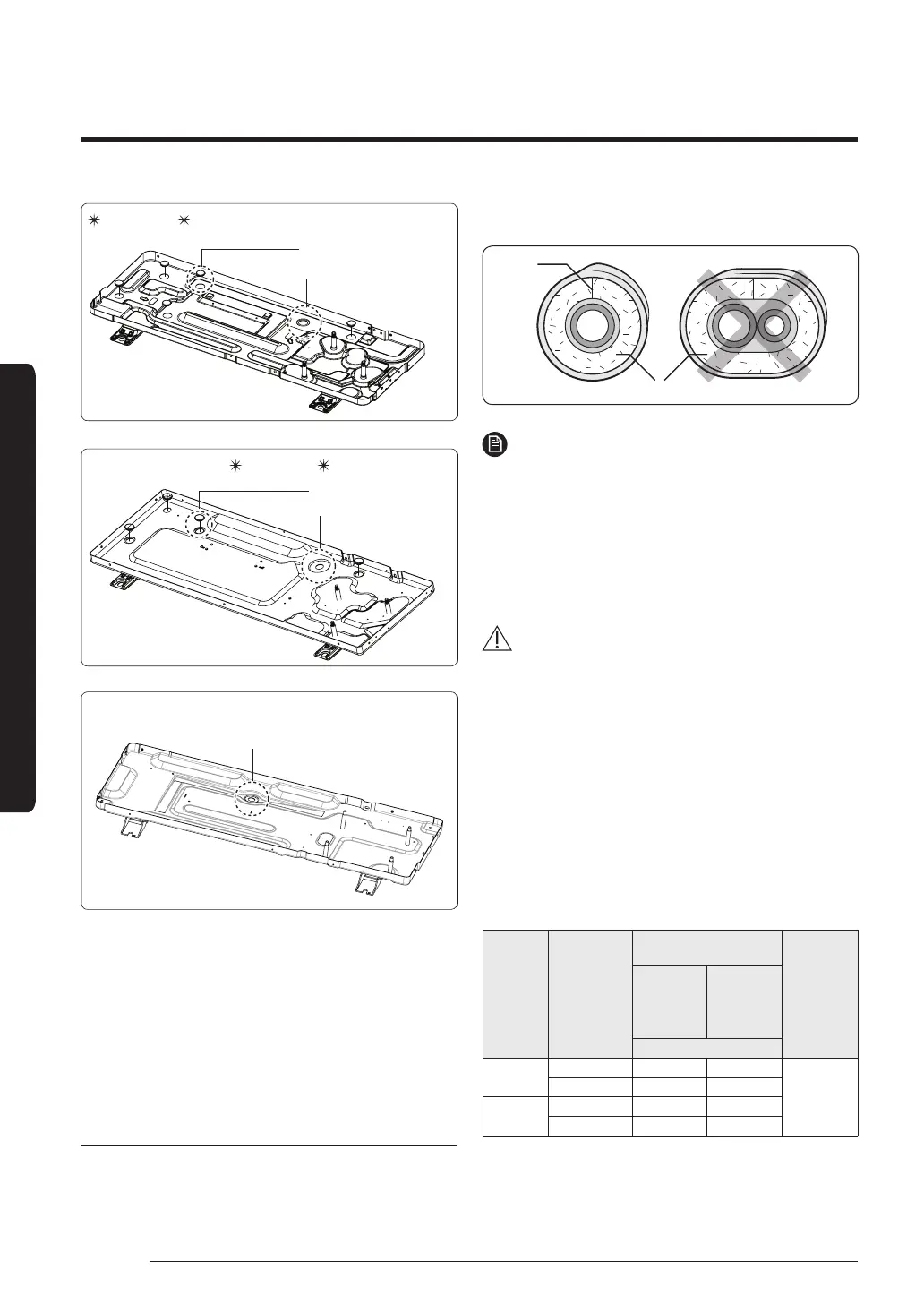

1 To avoid condensation problems, place an insulator

around each refrigerant pipe.

NOTE

• When insulate the pipe, be sure to overlap the

insulation.

• The insulation has to be produced in full compliance

of European regulation reg. EEC / EU 2037/ 2000

that requires the use of sheaths insulation form

without using CFC and HCFC gases for health and the

environment.

CAUTION

• When insulating the pipe, use non-slit insulator.

2 Select the insulation of the refrigerant pipe.

• Insulate the gas side and liquid side pipe referring

to the thickness according to the pipe size.

• Less than Indoor temperature of 30°C and

humidity of 85% is the standard condition. If

installing in a high humidity condition, use one

grade thicker insulator by referring to the table

below. If installing in an unfavourable conditions,

use thicker one.

• Insulator’s heat-resistance temperature should be

more than 120°C.

Pipe Pipe size

Insulation Type

(Heating/Cooling)

Remarks

Standard

[Less than

30°C, 85%]

High

humidity

[over 30°C,

85%]

EPDM, NBR

Liquid pipe

Ø6.35~Ø9.52 9 t 9 t

Internal

temperature

is higher than

120°C

Ø12.7~Ø19.05 13 t 13 t

Gas pipe

Ø6.35 13 t 19 t

Ø9.52~Ø19.05 19 t 25 t

• When installing insulation in places and conditions

below, use the same insulation that is used for

Loading...

Loading...