18

Installation Procedure

English

Installation Procedure

3 To prevent any gas from leaking out, remove all burrs

at the cut edge of the pipe, using a reamer.

4 ƊʒʪɇѤɇθʪЇϩͱϩͱϩ˵ʪΧΧʪɇʒͱʒ˙цϩ˵ʪѤɇθʪ

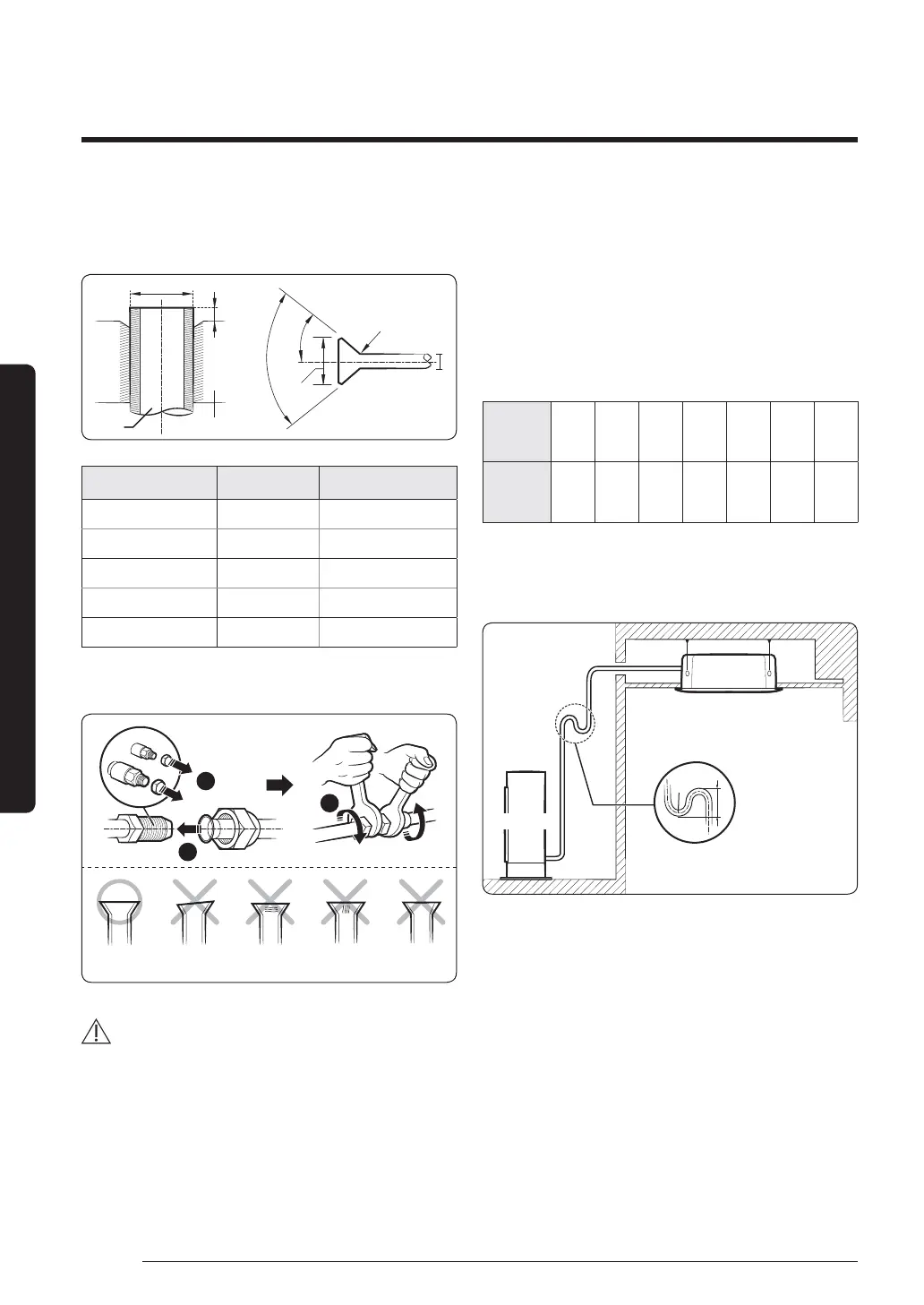

D

Flare

Flare

L

R 0.4 to 0.8 mm

90° ±2°

45° ±2°

D

Pipe

Outer diameter (D) Depth (A) Flare dimension (L)

ø 6.35 mm 1.3 mm 8.7 to 9.1 mm

ø 9.52 mm 1.8 mm 12.8 to 13.2 mm

ø 12.70 mm 2.0 mm 16.2 to 16.6 mm

ø 15.88 mm 2.2 mm 19.3 to 19.7 mm

ø 19.05 mm 2.2 mm 23.6 to 24.0 mm

5 A˵ʪʀϩ˵ɇϩϩ˵ʪѤɇθ˝ϑʀͱθθʪʀϩࡥθʪ˙ʪθθ˝ϩͱϩ˵ʪ

Їϑϩθɇϩͱϑɵʪͱи˙ͱθʪуɇΧʪϑͱ˙ʀͱθθʪʀϩѤɇθ˝

ߣ

ߤ

ߥ

Correct Inclined Damaged

Surface

Cracked Uneven

Thickness

CAUTION

• If the pipes require brazing ensure that OFN(Oxygen

Free Nitrogen) is flowing through the system.

• Nitrogen blowing pressure range is 0.02 to 0.05 MPa.

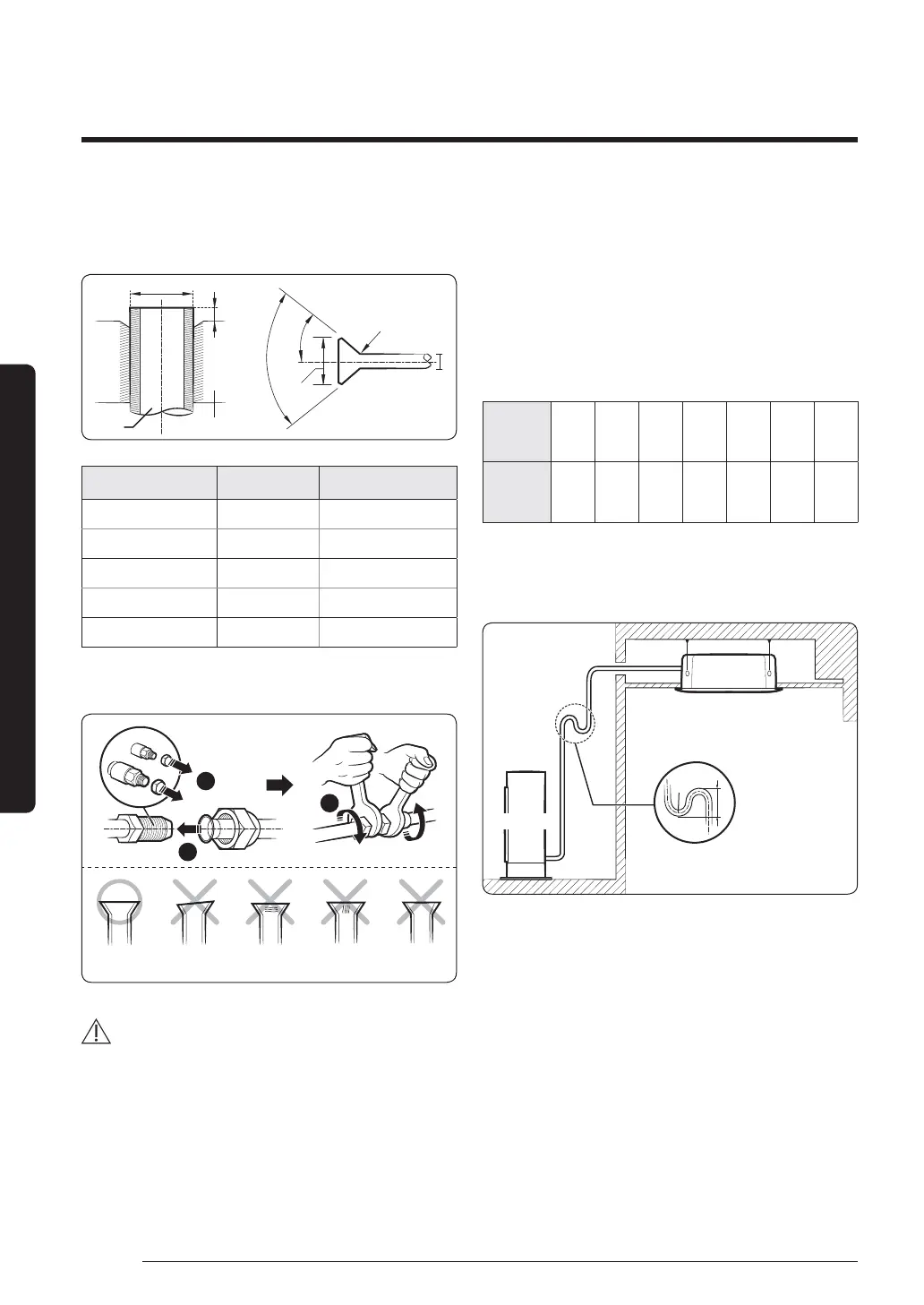

Step 7 Installing oil traps

Check the following list and install an oil trap.

• Based on cooling operation, install it on the gas side

pipe only.

• Install the oil trap only in between the outdoor unit

and the first branch joint and it should be installed at

every 10 m.

• Radius of curvature (R) on the oil trap are as follows;

Pipe

diameter

(D, mm)

12.70 15.88 19.05 22.23 25.40 28.60 31.75

Radius of

curvature

(R, mm)

25 and

over

32 and

over

38 and

over

41 and

over

51 and

over

57 and

over

60 and

over

• ²ʪ˝˵ϩͱ˙ϩ˵ʪͱϩθɇΧ࣑²࣒ࡤߦŵ²ߨŵ

• When the indoor unit is installed at a higher place than

the outdoor unit

Indoor Unit

Outdoor Unit

Oil trap (Install it at

every 10 m)

Loading...

Loading...