19

English

Installation Procedure

Step 8 Connecting up and removing air

in the circuit

CAUTION

• When installing, make sure there is no leakage. When

recovering the refrigerant, ground the compressor first

before removing the connection pipe. If the refrigerant

pipe is not properly connected and the compressor

works with the service valve open, the pipe inhales the

air and it makes the pressure inside of the refrigerant

cycle abnormally high. It may cause explosion and

injury.

The air in the indoor unit and in the pipe must be

evacuated. If air remains in the refrigerant pipes, it will

affect the compressor either reduce cooling capacity or

lead to a malfunction. Refrigerant for air purging is not

charged in the outdoor unit. Use Vacuum Pump as shown

ɇϩϩ˵ʪθ˝˵ϩѣ˝Їθʪ

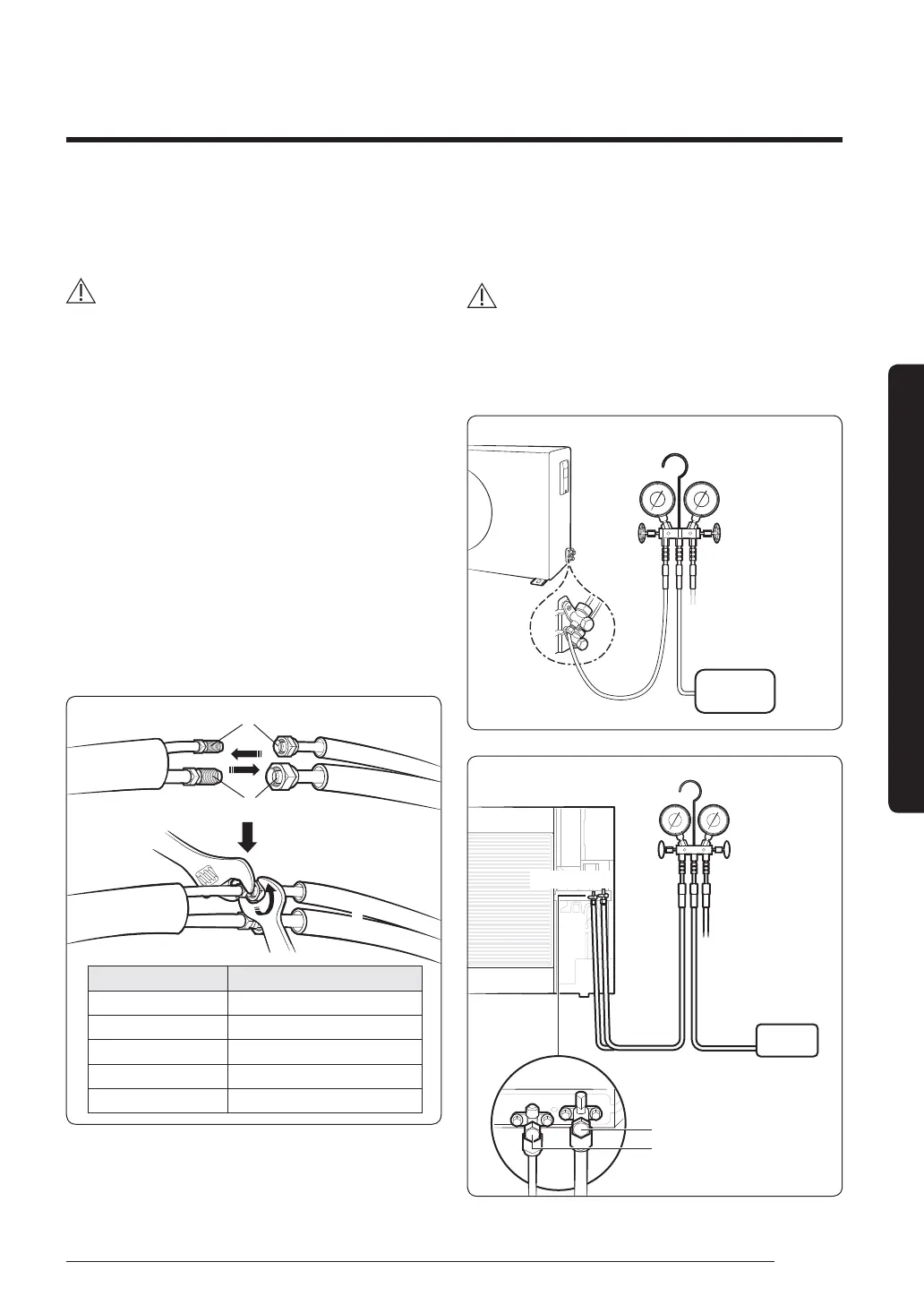

1 Connect each assembly pipe to the appropriate valve

ͱϩ˵ʪͱЇϩʒͱͱθЇϩɇʒϩ˝˵ϩʪϩ˵ʪѤɇθʪЇϩ

2 ŵʪ˙ʪθθ˝ϩͱϩ˵ʪЇϑϩθɇϩͱɵʪͱиࡥϩ˝˵ϩʪϩ˵ʪѤɇθʪ

ЇϩͱϑʪʀϩͱUѣθϑϩɇЇɇцɇʒϩ˵ʪиϩ˵ɇϩͱθαЇʪ

wrench, applying the following torque.

Outer Diameter (mm) Torque (N·m)

ø 6.35 14 to 18

ø 9.52 34 to 42

ø 12.70 49 to 61

ø 15.88 68 to 82

ø 19.05 100 to 120

A (Gas)

Outdoor Unit

B (Liquid)

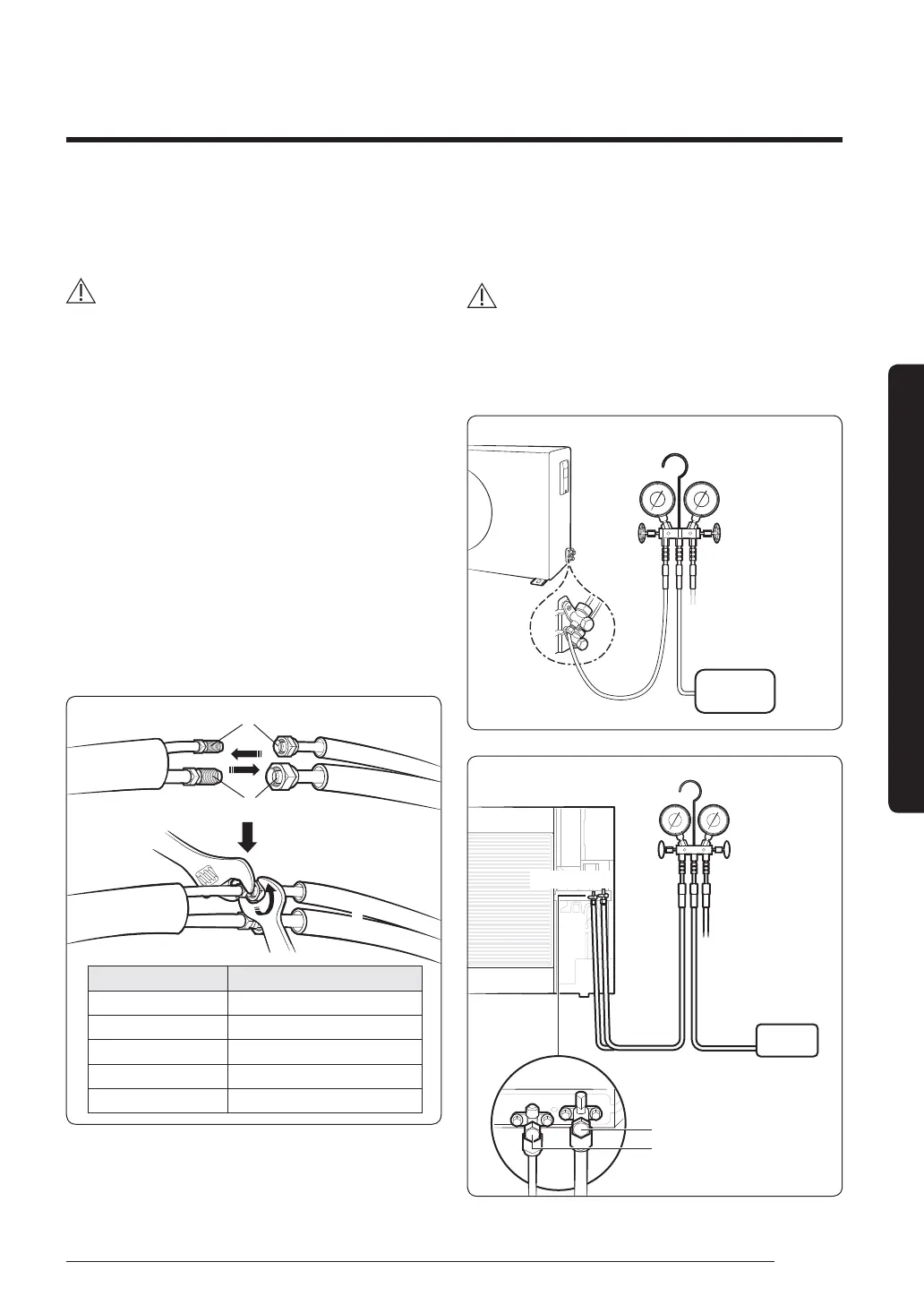

3 Connect the charging hose of low pressure side of

manifold gauge to the packed valve having a service

Χͱθϩɇϑϑ˵ͱиɇϩϩ˵ʪѣ˝Їθʪ

CAUTION

• The designs and shape are subject to change

according to the model.

4 Open the valve of the low pressure side(A) of manifold

gauge anticlockwise.

AC052/071TXADKC

Vacuum

pump

AC100/120/140/160TXAD*C

Vacuum

pump

Outdoor Unit

A (Gas)

B (liquid)

Loading...

Loading...