S&C ELECTRIC COMPANY

s

INSTRUCTION SHEET

716-501

Page 15 of 26

August 12, 2002

INSTALLATION — Continued

Next, attach the pole-unit channel base to the inter-

rupter-end support arm channel assembly. For Circuit-

Switchers rated 69 kV through 138 kV: Use ¹⁄₂—131¹⁄₂

hex-head galvanized steel cap screws, flat washers, and

self-locking hex nuts furnished. For Circuit-Switchers

rated 161 kV and 230 kV: Use ¹⁄₂—132 hex-head galva-

nized steel cap screws, flat washers, and self-locking hex

nuts furnished. Securely tighten the cap screws.

Finally, attach the pole-unit channel base to the discon-

nect-end support arm channel assembly.

For Circuit-

Switchers rated 69 kV through 138 kV: Use ¹⁄₂—131¹⁄₂

hex-head galvanized steel cap screws, flat washers, and

self-locking hex nuts furnished. For Circuit-Switchers

rated 161 kV and 230 kV: Use ¹⁄₂—132 hex-head galva-

nized steel cap screws, flat washers, and self-locking hex

nuts furnished. Securely tighten the cap screws. Shims are

furnished and should be installed as necessary between

the pole-unit channel base and the disconnect-end sup-

port arm channel assembly, to compensatae for any irreg-

ularities between the mating surfaces.

Step 14

Repeat Step 13 for the two outboard pole-units—marked

“Pole 1” and “Pole 3.”

Step 15

For 69-kV Circuit-Switchers with 48-inch phase spacing:

Relevel the interrupter-end support arm channel assembly

and disconnect-end support arm angle to the same eleva-

tion as the cross base. If necessary, loosen the cap screws

used to attach the outboard pole-unit channel bases to the

cross base, interrupter-end support arm channel assem-

bly, and disconnect-end support arm angle, and shift the

pole-units in order to level the channel assembly and sup-

port arm angle. Then securely tighten the cap screws.

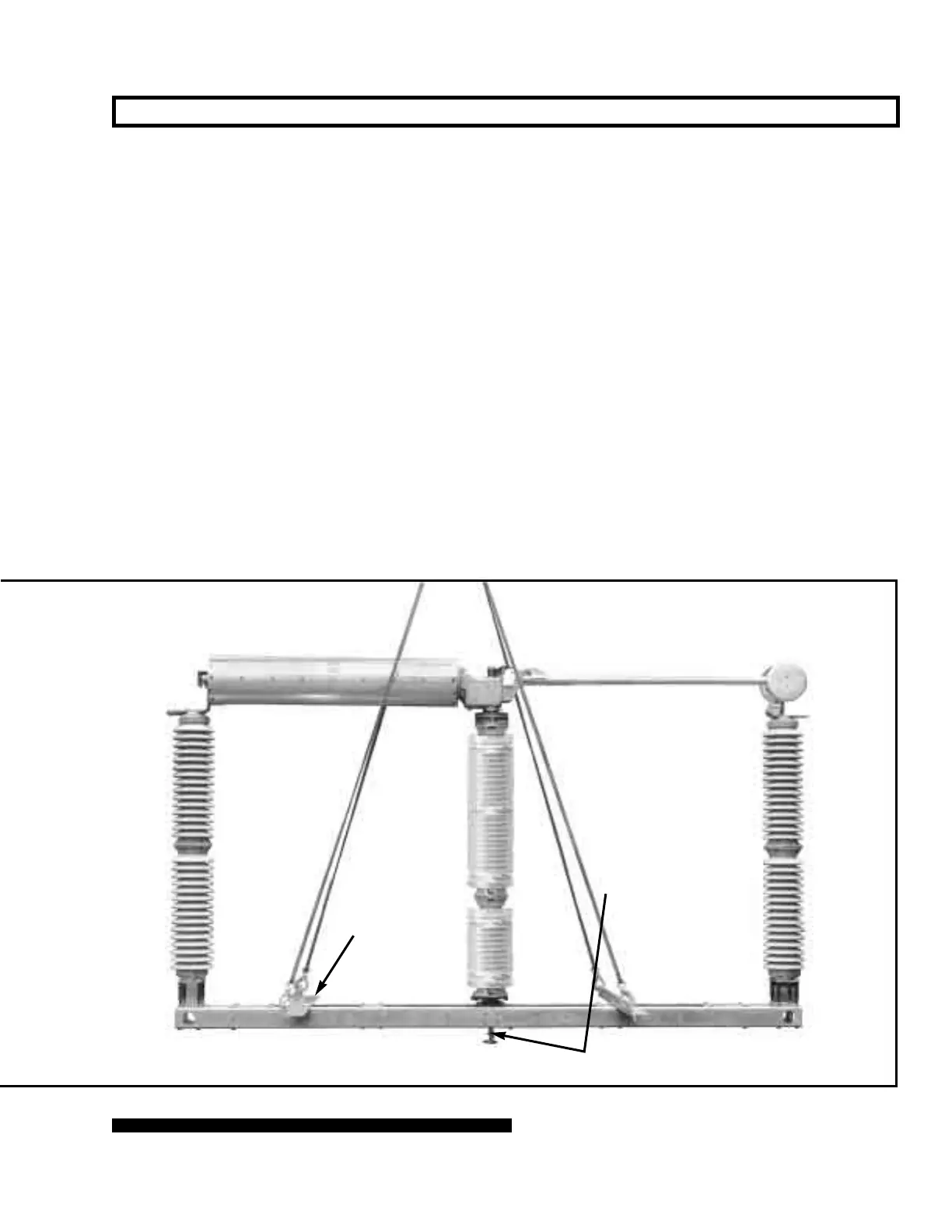

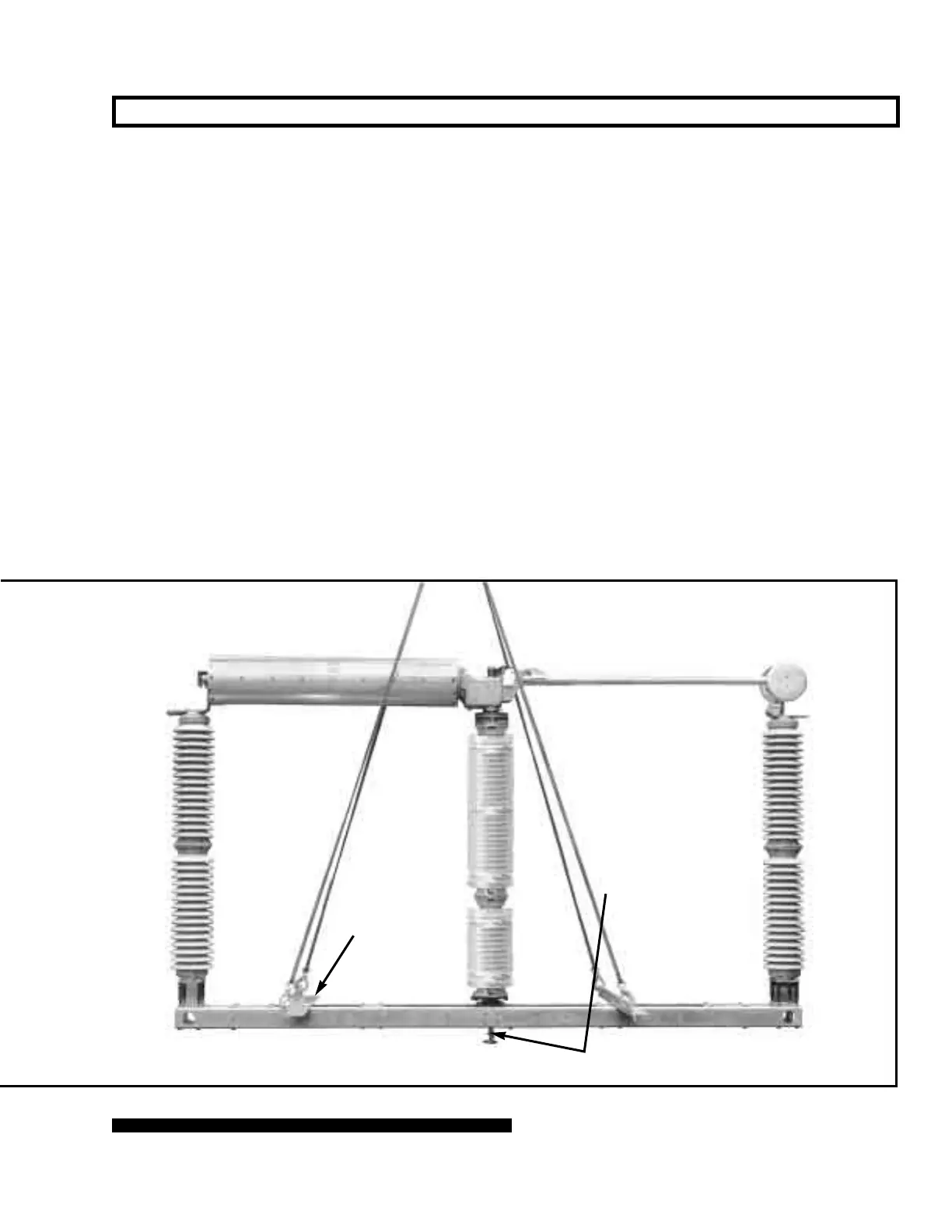

Disconnect-end support arm angle on 69-kV Circuit-Switchers with

48-inch phase spacing.

Circuit-Switchers rated 161 kV and 230 kV

Insulated operating rod

(shipping bracket removed

in photo)

Lifting

angles

Loading...

Loading...