20 S&C Instruction Sheet 761-507

Installation

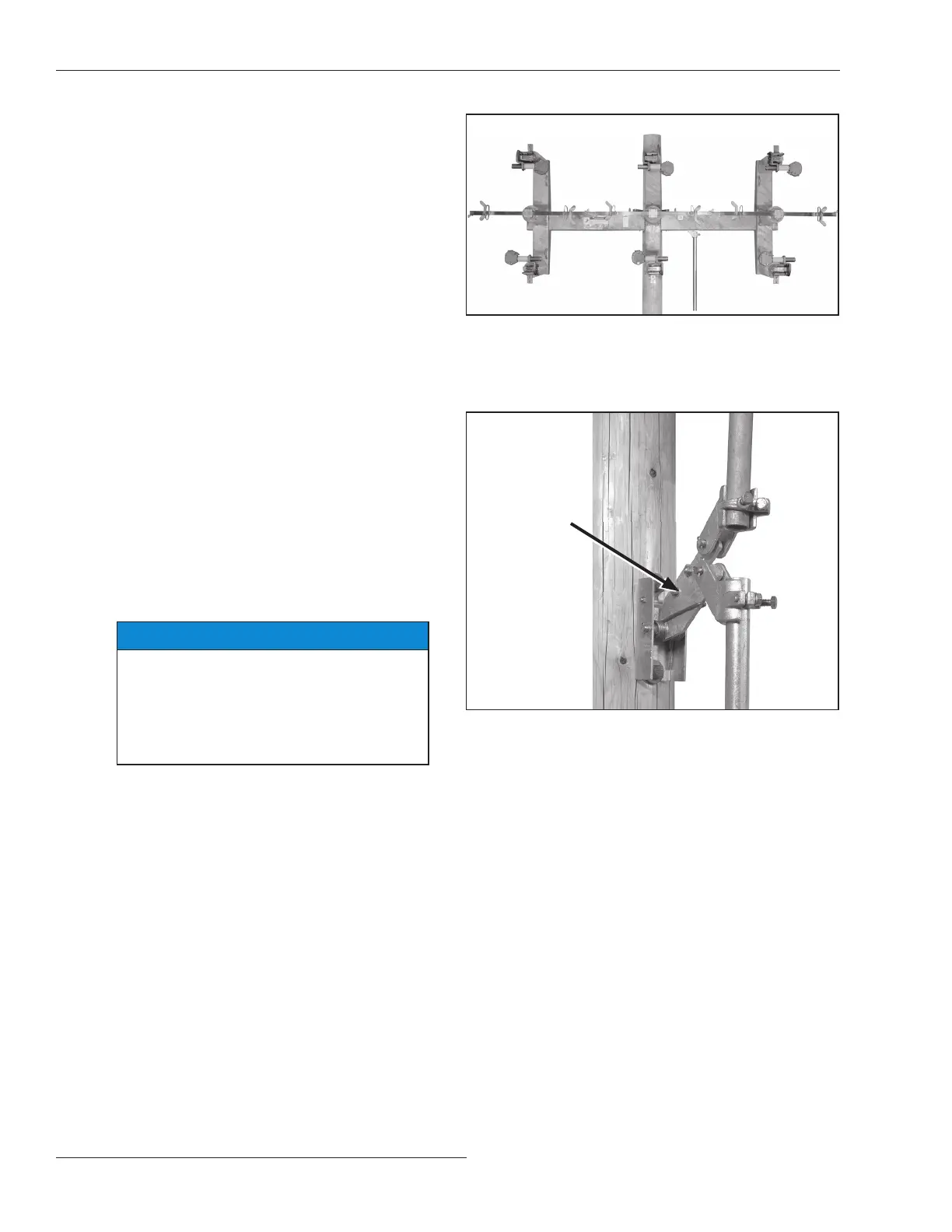

(b) With the operating handle as far as it will go in

the opening direction, the switch blades are 90

degrees from the Closed position. See Figure 30.

In the unlikely event that the above-described

conditions are not met, more switch blade travel

is required.

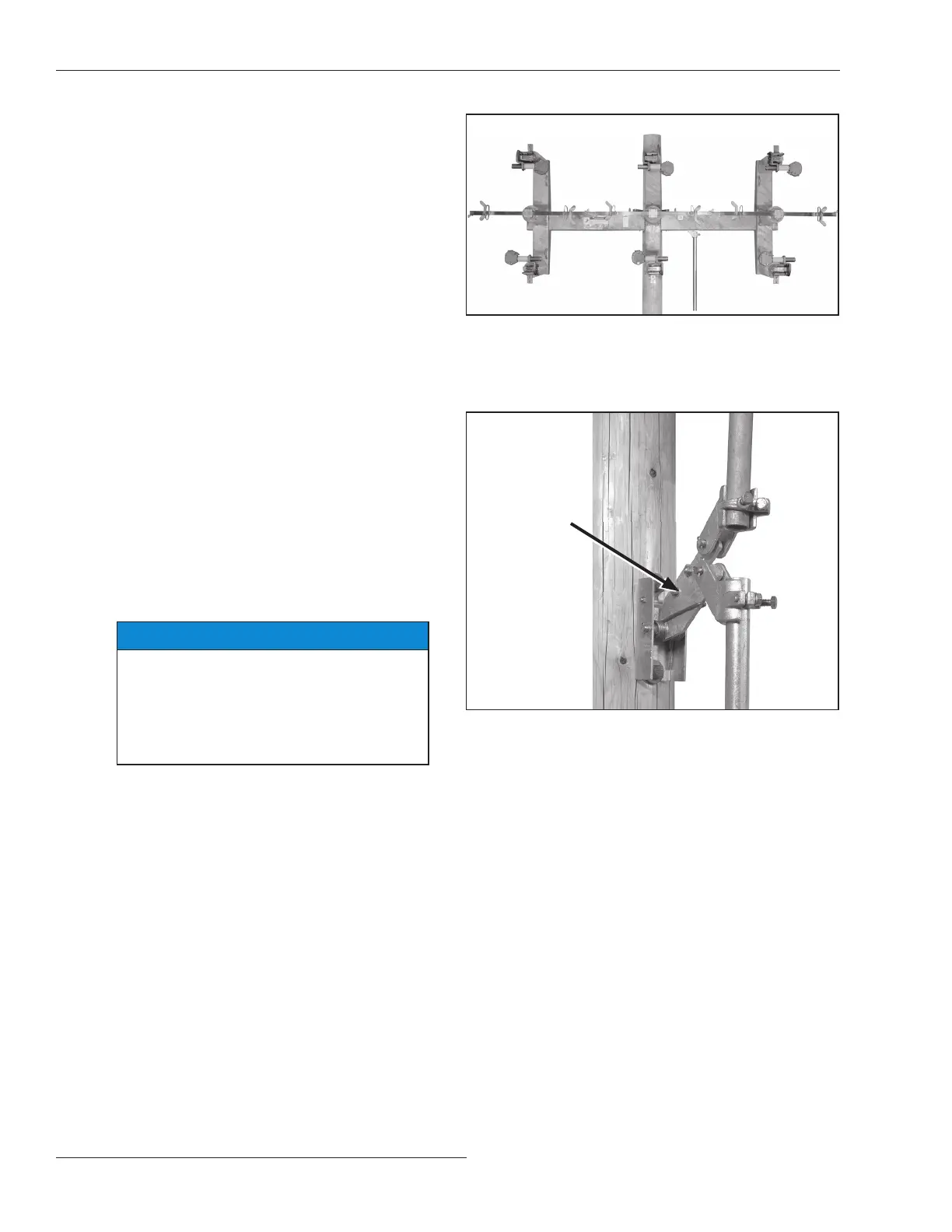

(c) Move the operating handle to its mid-posi tion to

take the strain off the operating-pipe linkage and

loosen the two bolts that clamp the driven arm of

the adjustable rod guide. See Figure 31.

(d) Lengthen the driven arm of the adjustable rod

guide one step ( -inch (9 mm)) and retighten

the bolts. Lengthening the driven arm increases

switch-blade travel. Then readjust for full

operating handle travel as described on page 18.

(e) Repeat this procedure—lengthening the driven

arm of the adjustable rod guide in one-step

increments and readjusting for full oper ating

handle travel—until full switch-blade travel is

attained.

(f) When satisfactory travel adjustment of the

operating handle and switch have been attained,

torque the bolts on the driven arm of the

adjustable rod guide, and the clamp bolt on the

rod guide (or switch drive lever) cou pling to nal

tightness. Then, tighten the asso ciated piercing

set screw, piercing the pipe, and continue turning

until a rm resistance is felt.

NOTICE

After readjusting, be sure to retighten the

clamp bolt and piercing set screw on the

pipe coupling at the rod guide (or switch

driver lever) immediately above the operat-

ing handle and the clamp bolts on the

driven arm of the adjustable rod guide.

Figure 31. Lengthening the driven arm of the adjustable rod guide.

Driven arm

Figure 30. Checking that the switch blades are 90 degrees from

the Closed position.

Loading...

Loading...