s a n d p i p e r p u m p .c o m

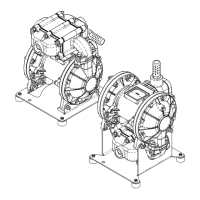

Model SA1

& SA25

Heavy Duty Flap Valve

Design Level 5

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Manseld, Ohio 44902 USA

Telephone (419) 524.8388

Fax (419) 522.7867

SANDPIPERPUMP.COM

© Copyright 2017 Warren Rupp, Inc.

All rights reserved

10.69

271

12.38

314

11.36

288

"C"

5.29

134

3.79

96

"A"

"B"

2.89

73

AIR EXHAUST

3/4" FNPT

SUCTION PORT

1" FNPT (SA1)

1" BSPT (SA25)

AIR INLET

1/2" FNPT

DISCHARGE PORT

1" FNPT (SA1)

1" BSPT (SA25)

9.00

229

8.56

217

4X

.28 [7] MOUNTING HOLE

NOTE:

UNIT FURNISHED WITH SUB-BASE PLATE

AND RUBBER FEET AS STANDARD. FOR

STATIONARY BOLT DOWN USE, RUBBER

FEET CAN BE REMOVED.

SA1 / SA25

HEAVY DUTY FLAP VALVE PUMP

TOP PORTED

DIMENSIONAL TOLERANCE

1/8 [3]

[XX] = MILLIMETERS

SUCTION & DISCHARGE CONNECTIONS

SA1

1" NPT FEMALE THREADED

CONNECTIONS

SA25

1" BSP TAPERED FEMALE THREADED

CONNECTIONS

PUMP

CONFIGURATION

DIM "A" DIM "B"

DIM "C"

ALUMINUM

CENTER SECTION

3.95 [100] 5.86 [149] 11.11 [282]

CAST IRON

CENTER SECTION

4.10 [104] 5.54 [141] 11.26 [286]

PULSE OUTPUT

CONFIGURATION

2.45

62

11.36

288

"D"

"A"

"B"

"C"

3.79

96

5.29

134

6.89

175

AIR EXHAUST

3/4" FNPT

DISCHARGE PORT

1" FNPT (HDF1)

1" BSPT (HDF25)

AIR INLET

1/2" FNPT

SUCTION PORT

1" FNPT (HDF1)

1" BSPT (HDF25)

9.00

229

8.56

217

4X

.28 [7] MOUNTING HOLE

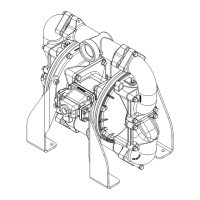

NOTE:

UNIT FURNISHED WITH SUB-BASE PLATE

AND RUBBER FEET AS STANDARD. FOR

STATIONARY BOLT DOWN USE, RUBBER

FEET CAN BE REMOVED.

SA1 / SA25

HEAVY DUTY FLAP VALVE PUMP

BOTTOM PORTED

DIMENSIONAL TOLERANCE

1/8 [3]

[XX] = MILLIMETERS

PUMP

COFIGURATION

DIM "A" DIM "B"

DIM "C" DIM "D"

ALUMINUM

CENTER SECTION

3.95 [100] 5.86 [149] 11.11 [282] 14.55 [370]

CAST IRON

CENTER SECTION

4.10 [104] 5.54 [141] 11.26 [286] 15.75 [400]

PULSE OUTPUT

CONFIGURATION

SUCTION & DISCHARGE CONNECTIONS

SA1

1" NPT FEMALE THREADED

CONNECTIONS

SA25

1" BSP TAPERED FEMALE THREADED

CONNECTIONS

Certied Quality

ISO 9001 Certied

ISO 14001 Certied

SERVICE & OPERATING MANUAL

Original Instructions

1: PUMP SPECS2: INSTAL & OP3: EXP VIEW4: AIR END5: WET END6: OPTIONAL7: WARRANTY