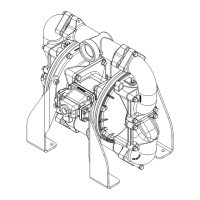

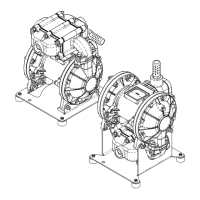

How to fix product leaking through the exhaust of my Sandpiper Signature?

- TtonyajonesAug 27, 2025

If you notice product leaking through the exhaust of your Sandpiper Control Unit, it's likely due to diaphragm issues. This could be caused by diaphragm failure, or loose diaphragm plates, in which case you should replace the diaphragms and ensure the diaphragm plates are tight. Another potential cause is the diaphragm being stretched around the center hole or bolt holes. Check for excessive inlet pressure or air pressure and consult the Chemical Resistance Chart for compatibility with products, cleaners, temperature limitations, and lubrication.