- 32 -

8. Diagnosis of abnormal cooling circuit

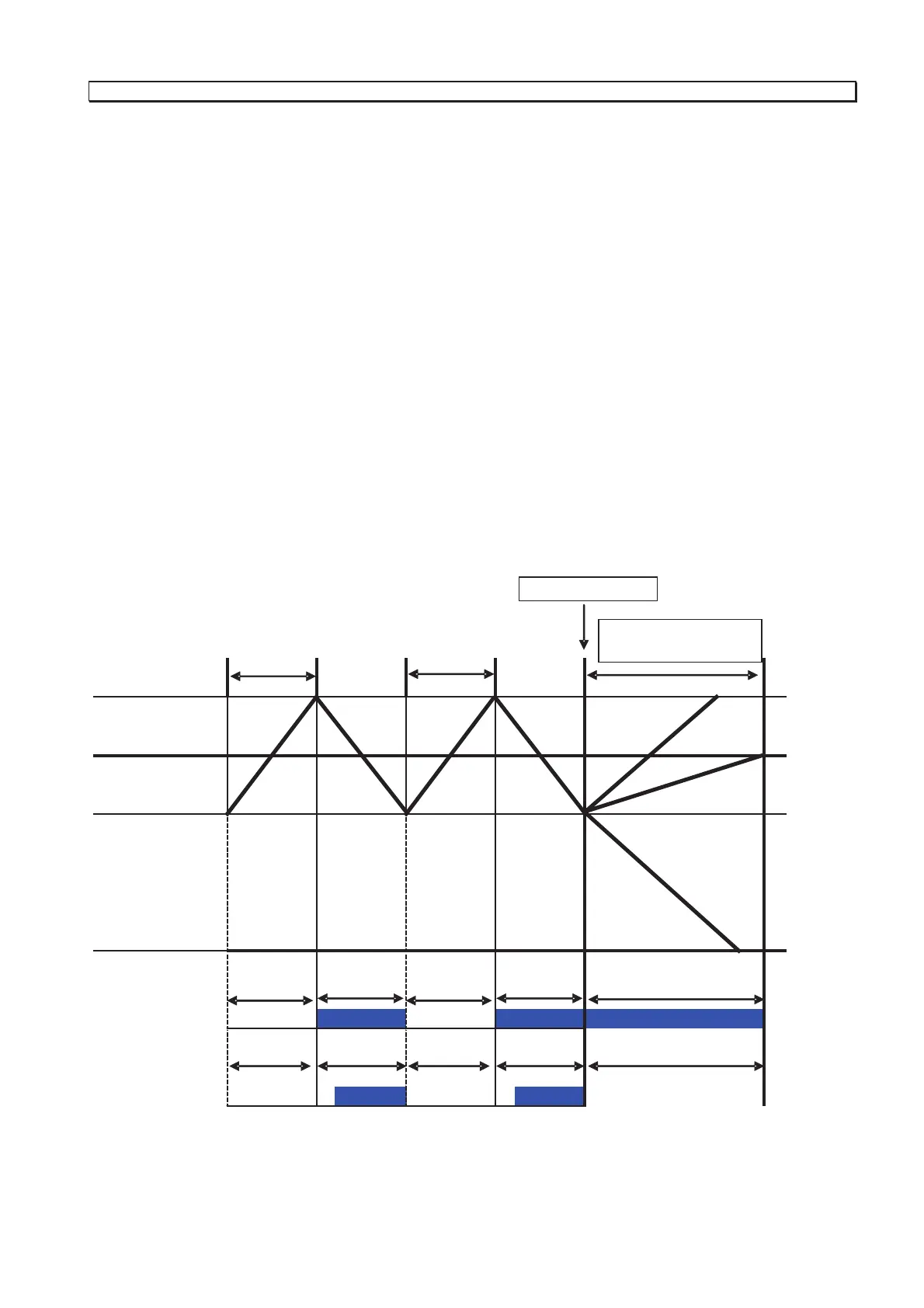

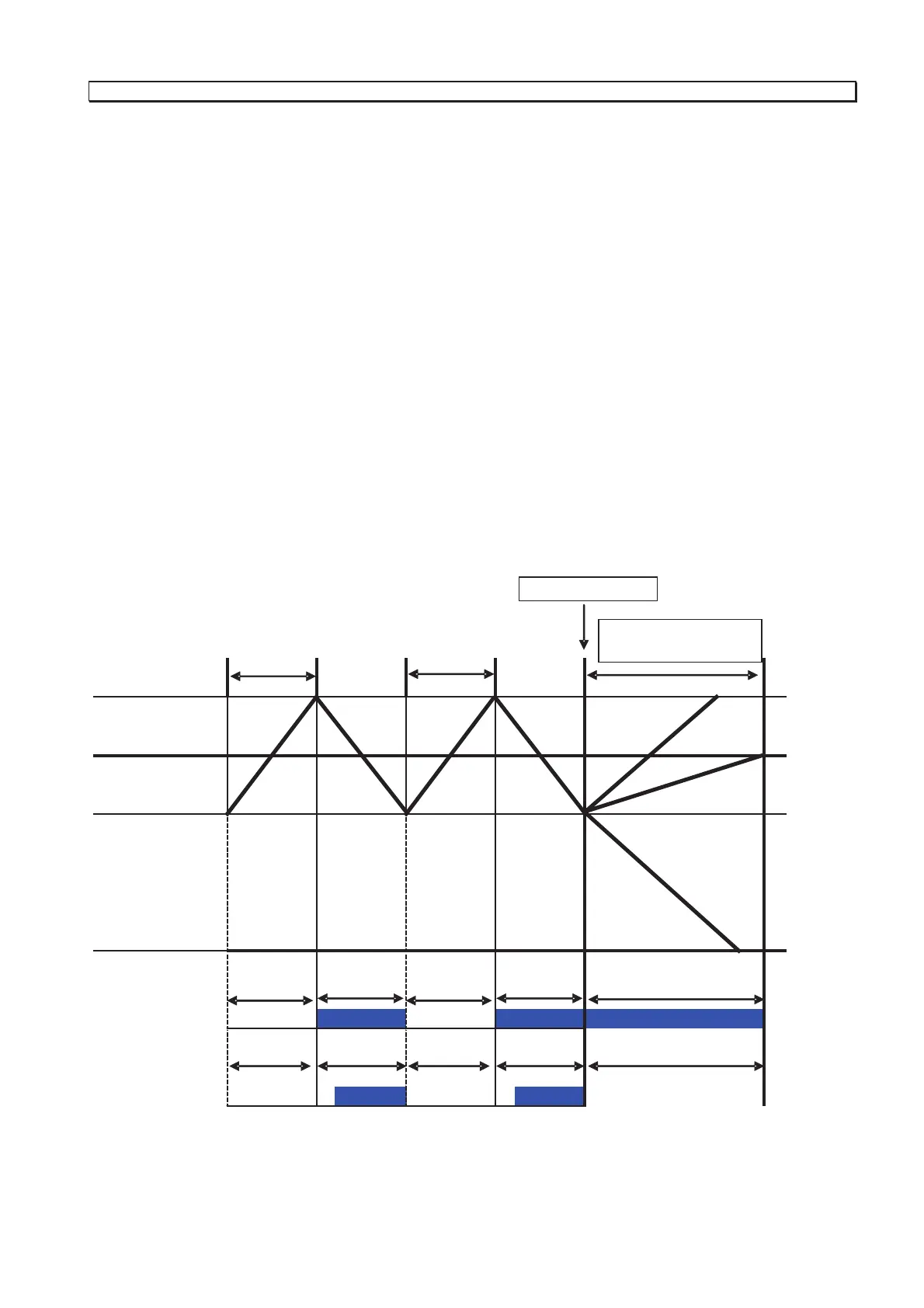

(1) Normal mode

㽲㩷 Frequency: Diagnosis is performed for once per day (2:00a.m. or later) on either compressor A and B.

Diagnosis of compressor A is done first.

(Ex.) After the power is supplied, diagnosis of compressor A is performed at 2:00a.m. or later.

Diagnosis of compressor B is performed the next day.

㽳㩷 2 portions of pull-up time just before diagnosis (㽳 indicated in the picture below) are stored.

㽴 Calculation of period for diagnosing cooling circuit: (ǻT1+ǻT2)/2x1.1 (Ԛ indicated in the picture below)

Diagnosis pattern

a. When unit reaches set temp -2.0㷄 beyond the OFF point (set temp -0.6㷄) during a single compressor

cycle, the diagnosis is considered 㵰Normal㵱 that the unit can keep cooling performance.

(Line-a indicates in the picture below)

b. When unit keeps temperature almost near set temp and diagnosis period expires, the diagnosis is

considered 㵰Normal㵱 that the unit can keep cooling performance.

(Line-b indicates in the picture below)

c. When unit reaches the ON point (set temp +0.6㷄) during diagnosis, the diagnosis is considered

㵰Abnormal㵱 that the unit cannot keep cooling performance because temperature increases is the same

as pull-up temperature except in cycle operation. (Line-c indicates in the picture below)

ĺ Diagnosis will be performed again 48 hours later and it will be determaind as a 㵬failure㵭 in cooling

circuit if the results are the same.

㩷

ON

䋨Set temp+0.6㷄䋩

Chamber temp

OFF

(Set temp-0.6㷄)

Diagnosis OFF

(Set temp-2.0㷄)

Comp 䌁

Comp 䌂

of

of

on

on

of

of

on

on

㽳Pull-up time

㰱㪫㪈

㽳Pull-up time

㰱䌔㪉

of

on

㽴Diagnosis period

㩿Ʀ㪫㪈㪂Ʀ㪫㪉㪀㪆㪉×㪈㪅㪈

㽲Diagnosis point

㪸

㪹

㪺

Loading...

Loading...