01:03-02

©

Scania CV AB 2011, Sweden

105

Machining crankshafts

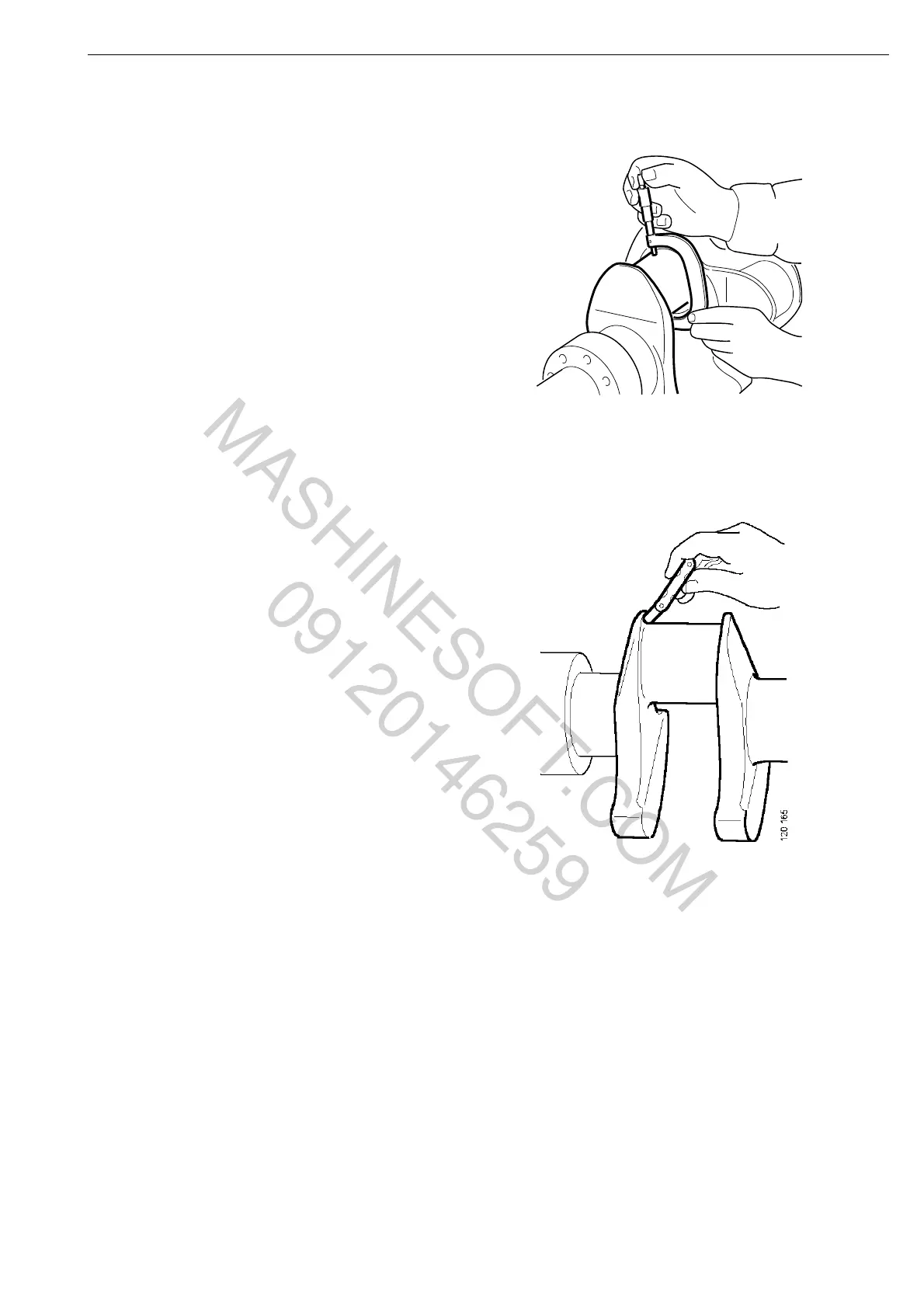

1 Measure the diameter on the crankshaft

bearing journals using a micrometer as

illustrated. Measure at several points around

the bearing journal. If any of these

diameters is lower than the minimum

indicated limit, regrinding of the crankshaft

should be considered. Oil pressure should

also be checked, as it is affected by such

factors as wear in the main bearings and

connecting rod bearings.

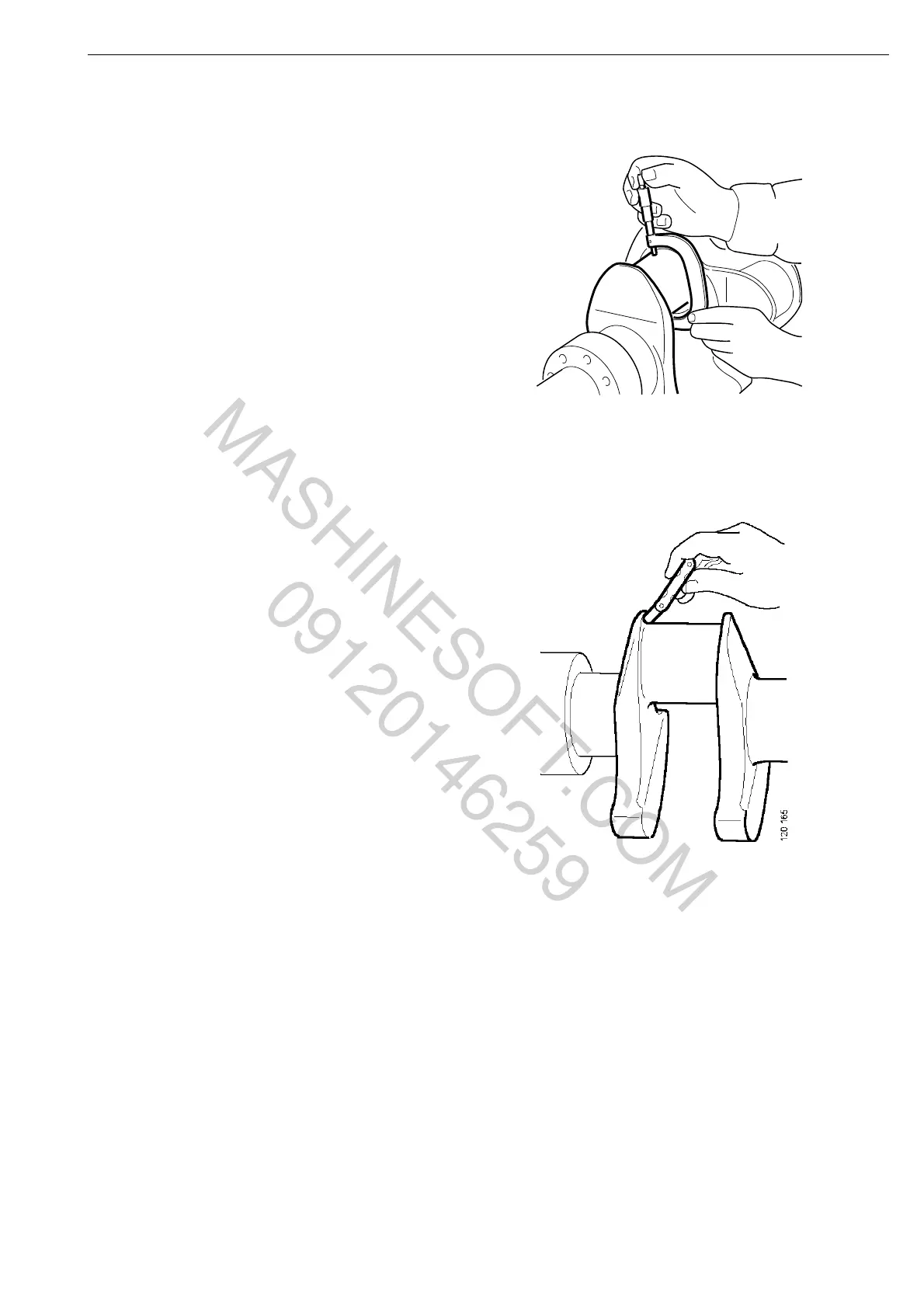

2 When regrinding, keep to the specified

minimum dimensions. Suitable bearings are

available for these sizes. It is important that

the fillet radius of the bearing journals is

correct. Check the fillet radius using a

template as illustrated.

3 After grinding the bearing journals, round

off and polish the oil hole openings on the

bearing surfaces.

Crankshaft

MASHINESOFT.COM

09120146259

Loading...

Loading...