TROUBLESHOOTING

42 | EN www.schmalz.com 30.30.01.00174/06

8 Troubleshooting

The vacuum tube lifter JUMBO must only be installed and maintained by qualified specialist personnel,

mechanics and electricians. Work on electrical equipment must be carried out by qualified electrical

specialists only.

After repair and maintenance work, always check the safety features as

described in section 9.2 “Check safety features”.

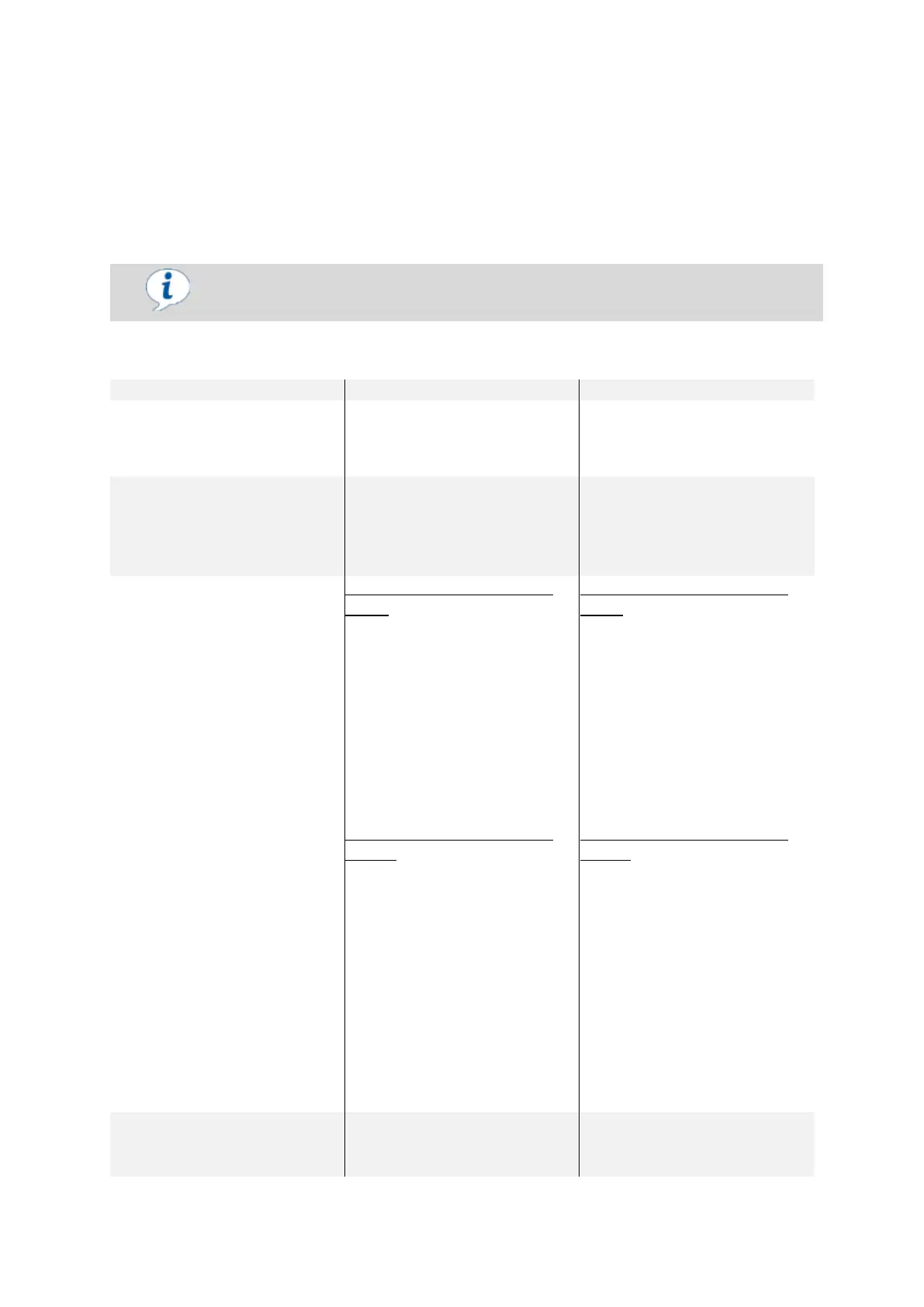

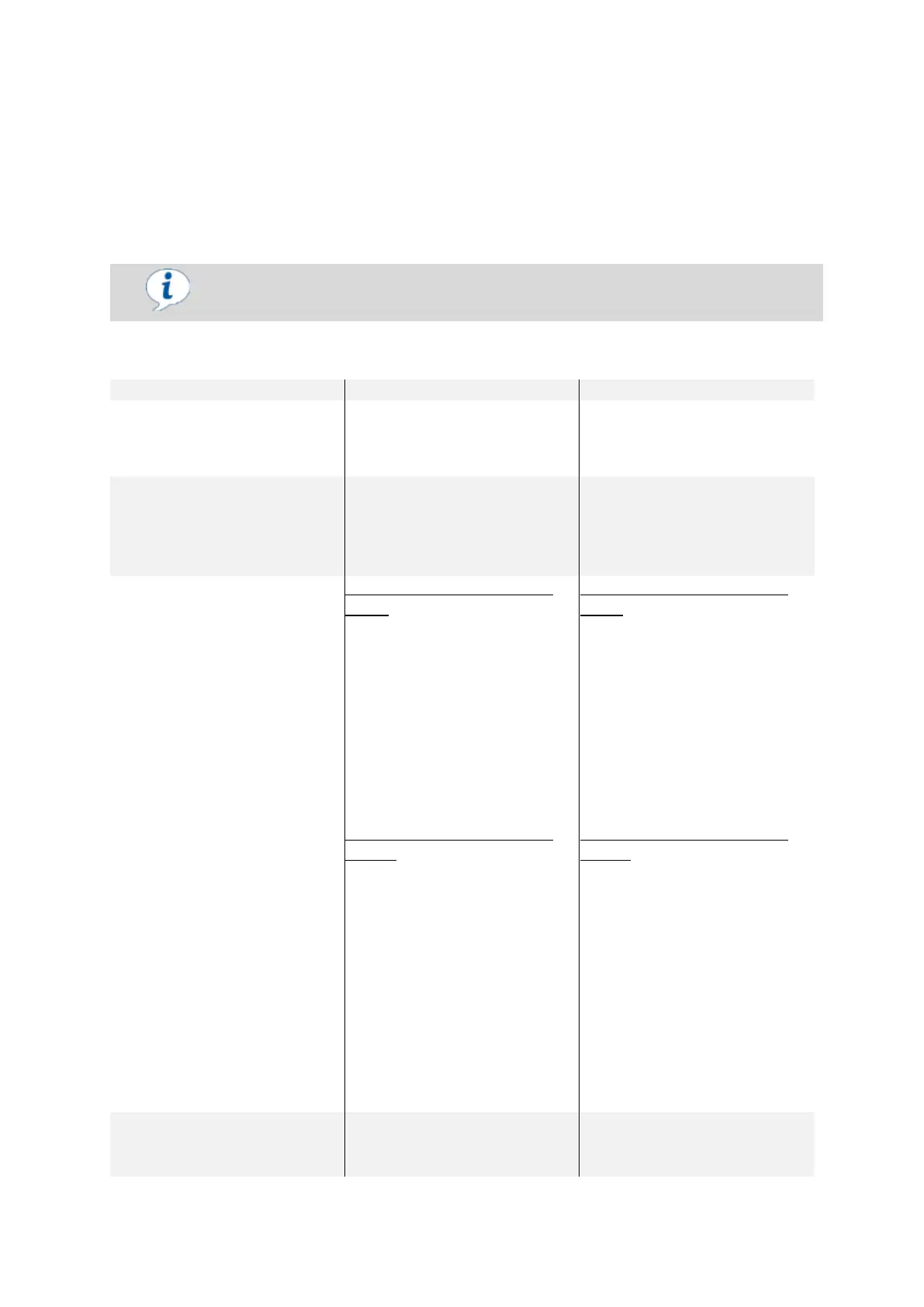

If the load cannot be lifted, work through the following list to identify and rectify the problem.

Pump rotation direction

reversed

Reverse the polarity of the pump

phases

- Use equipment to measure

the rotating field

- Use an automatic phase

sequence indicator

Check the electrical connection:

- Check the power supply line

- Check for voltage on all phases

Required vacuum not attained

Vacuum tube lifter JUMBO with

pump:

- Examine the supply hose and

tube lifter for cracks

- Check gripping mechanism

- Clean dust filter cartridge and

filter of the operator handle

(for Flex 20/35) and pump or

replace if necessary

- Check pump for faults. See

separate pump instructions

Vacuum tube lifter JUMBO with

pump:

- Increase filter maintenance

interval (see section 9.7)

- Consult with the

manufacturer

Vacuum tube lifter JUMBO with

ejector:

- Examine the compressed air

hose and tube lifter for cracks

- Check gripping mechanism

- Clean or replace the filter of

the operator handle (for Flex

20/35)

- Clean the silencer of the

vacuum generator

Vacuum tube lifter JUMBO with

ejector:

- Increase filter maintenance

interval (see section 9.7)

- Increase maintenance

interval for the filter in the

ejector

The load is too porous or non-

rigid

- The load cannot be lifted; use

a different suction pad for

non-rigid parts

- Decrease the load, use a

different lifting device

- Ensure that the workpiece to

be lifted does not exceed

the maximum load

Loading...

Loading...