Copyright © 2021 Axxiom Manufacturing, Inc.

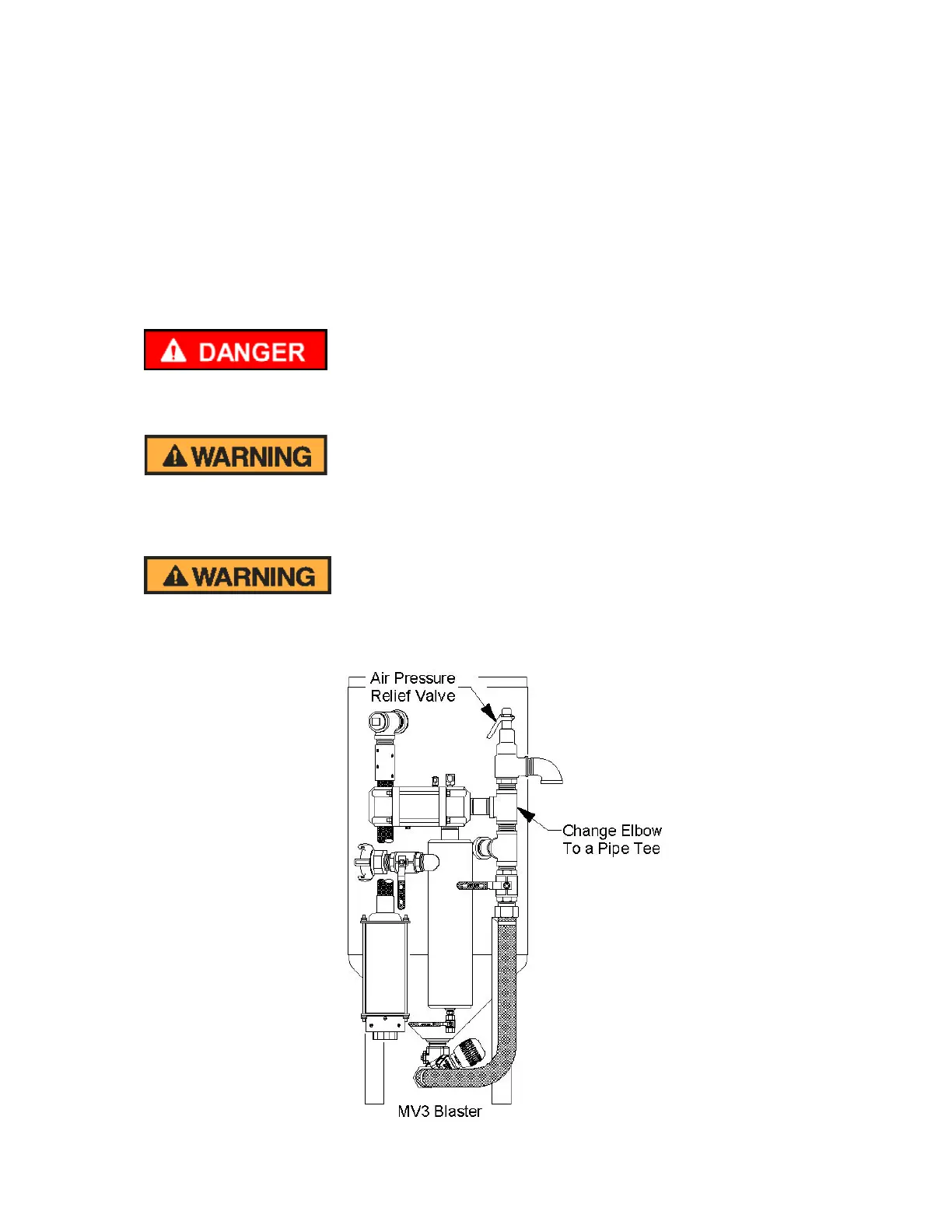

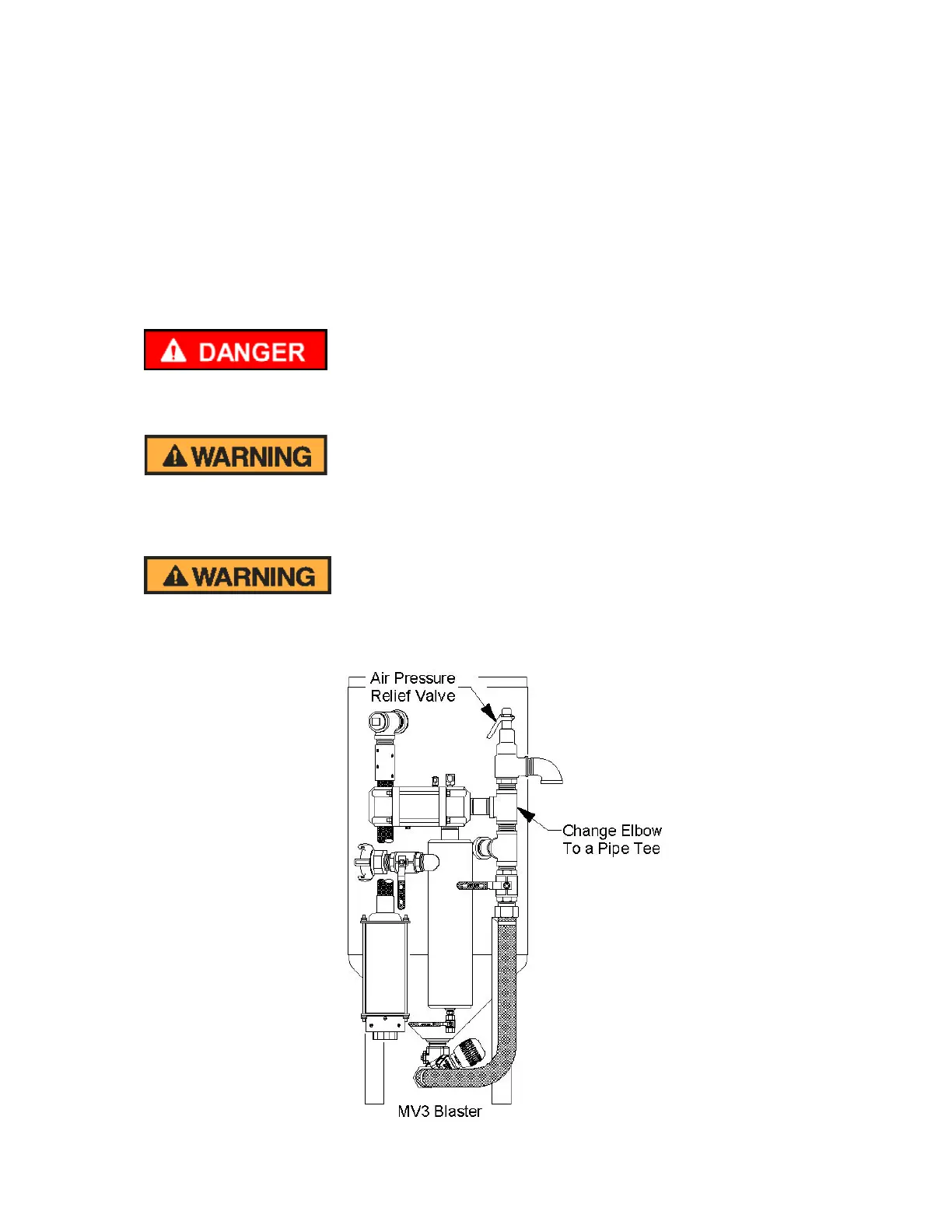

3.11 Pressure Relief Valve Installation

Do Not operate this equipment without a pressure relief device installed to protect the blaster

pressure vessel from over-pressurization. The ASME Code requires that all vessels be operated

with pressure relief devices in place.

If the compressed air system does not provide for the installation of a pressure relief valve one

can be installed on the pressure vessel piping. Refer to Figure 3.11 for the recommended

location of the air pressure relief valve.

Local regulations set the specifications for pressure relief valves; therefore, it is the

responsibility of the owner of the abrasive blaster to install a pressure relief valve that meets all

applicable regulations. The pressure relief device must be set at the maximum allowable

working pressure of the abrasive blaster pressure vessel See the ASME/CE vessel nameplates

attached to the pressure vessel.

Rupture Hazard. Operating the pressure vessel above the maximum allowable working pressure

can result in rupturing the pressure vessel. Install an air pressure relief valve to protect against

over pressurization of the blast vessel.

Airborne particles and loud noise hazards from relief valve exhaust air can cause serious injury

and loss of hearing. Wear approved eye and ear protection. Stay clear of exhaust air path. DO

NOT place hands or other body parts in the exhaust air path. Make sure no personnel are in the

exhaust air path. Direct the relief valve exhaust away from work area.

In special cases at the request of customer, a pressure relief valve may be included with the

equipment. It is the responsibility of the owner/user to confirm that the supplied pressure relief

valve meets all local regulations.

Figure 3.11 – Suggested location for air pressure relief valve

Loading...

Loading...