Copyright © 2021 Axxiom Manufacturing, Inc.

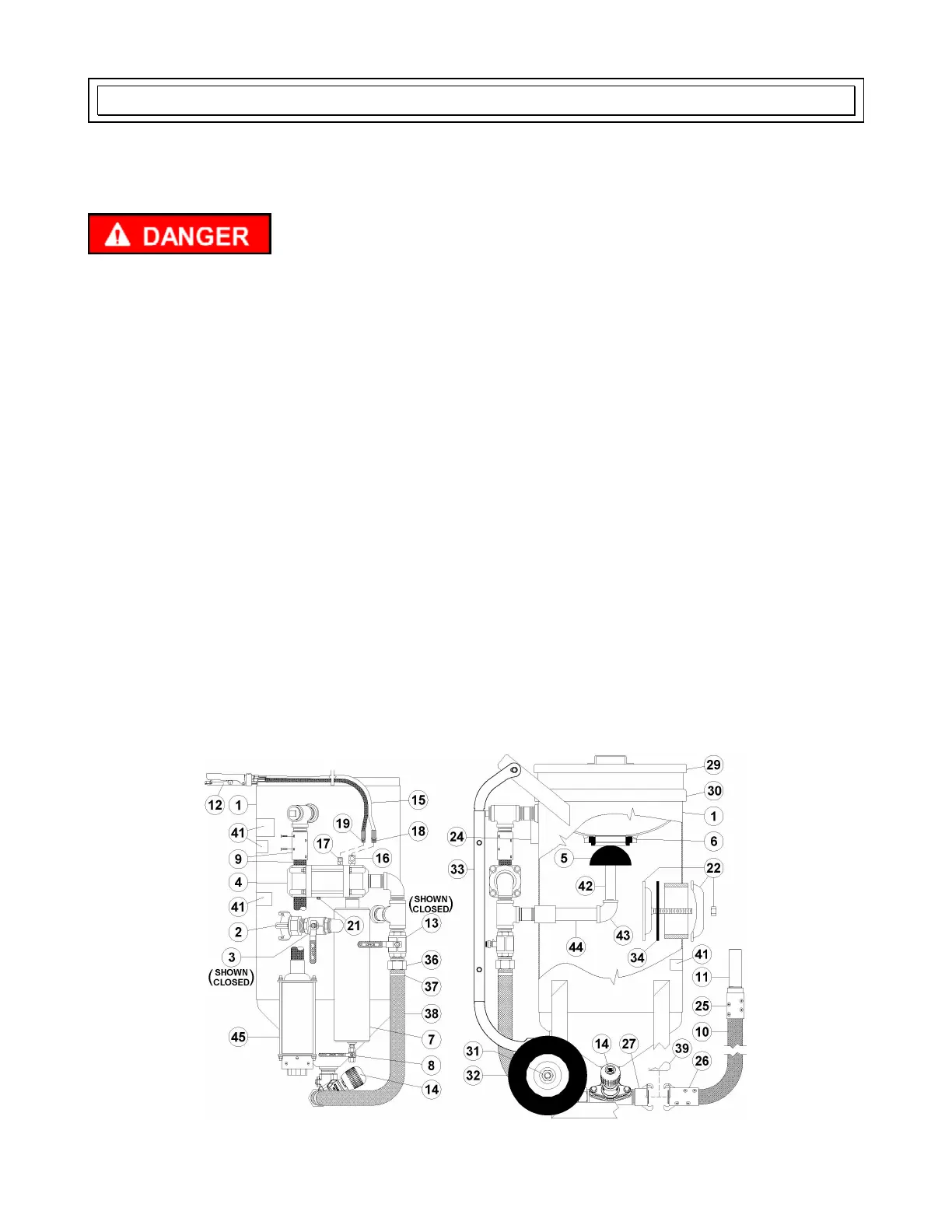

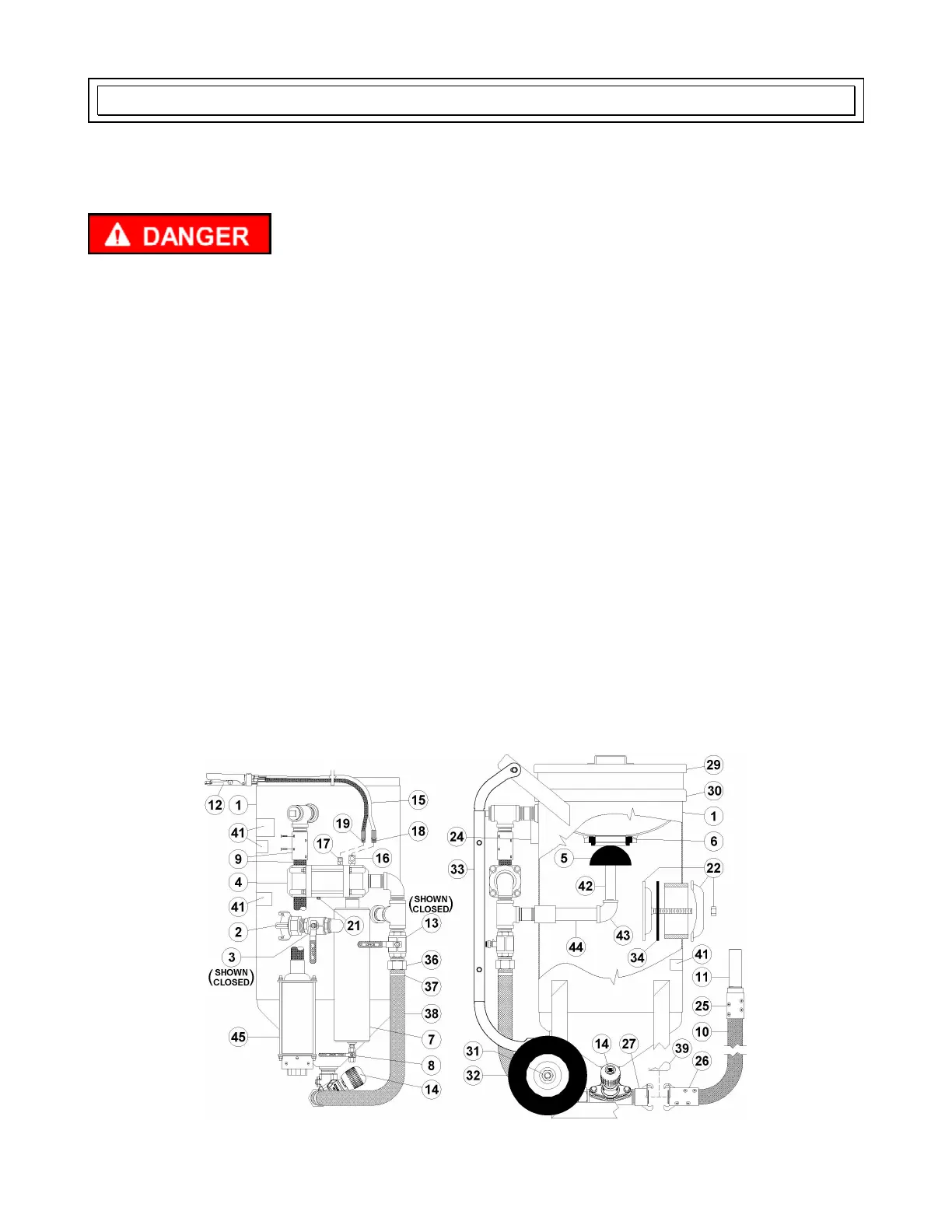

This section lists probable causes of problems that may occur during operation of the abrasive blaster.

Not all the “probable causes” may apply to your abrasive blaster. The probable cause may not apply

because of the control type and accessories on the abrasive blaster. Refer to Figure 11.1 and the

drawings in Section 9.0.

The MV3 Valve abrasive blaster is a Pressurized Vessel. Propelled objects will cause serious injury or

death. Depressurize vessel before performing any maintenance. See Section 6.2.

11.1 Malfunction with Deadman Lever in the “Off” Position

11.1.1. Abrasive stops but blast air will not shut off

(1) Defective or broken valve plug assembly in ComboValve® (#4).

(2) Defective ComboValve (#4) lower rod guide seal.

11.1.2. Both blast air and abrasive will not shut off

(1) Twinline hoses to deadman valve (#12) are crossed.

(2) Non-Schmidt deadman (#12) has been installed.

(3) Control valve (#20) stuck in the “ON” position. (MV3 Electric only)

(4) Blocked twinline hose.

(5) Defective deadman valve (#12). Pneumatic deadman cartridge plunger stuck in the “ON”

position (down). Cartridge plunger is visible below deadman handle.

(6) Defective or broken ComboValve (#4) spring.

(7) Defective ComboValve (#4) lower rod guide seal.

11.1.3. Blast outlet turns on accidentally

(1) The deadman lever (#12) is worn out.

(2) The safety button on the deadman is missing. See drawings in Sections 9.8 and 9.9.

(3) A bleeder type deadman valve has been installed. A bleeder type deadman valve is not safe

because a particle of dirt from the air hose can plug the bleed hole and cause the blast outlet

to turn on. See Warnings and Rules for Safer Operation in Section 1.0.

(4) Defective electric deadman switch or electric wiring (check for an electric short).

(5) Defective ComboValve (#4) lower rod guide seal.

Figure 11.1 – MV3 Valve Abrasive Blaster with pneumatic blast controls

Loading...

Loading...