Copyright © 2021 Axxiom Manufacturing, Inc.

7.1 Filling the Abrasive Blaster with Abrasive

`

7.1.1. The Abrasive blaster must be completely depressurized before filling with abrasive.

Follow the depressurizing procedure in Section 6.2. Disable the blaster by closing the

air inlet ball valve (#3).

Airborne particles and loud noise hazards from blowdown exhaust air can cause serious

injury and loss of hearing. Wear approved eye and ear protection. Stay clear of

blowdown air path. DO NOT place hands or other body parts in the blowdown air path.

Make sure no personnel are in the blowdown air path.

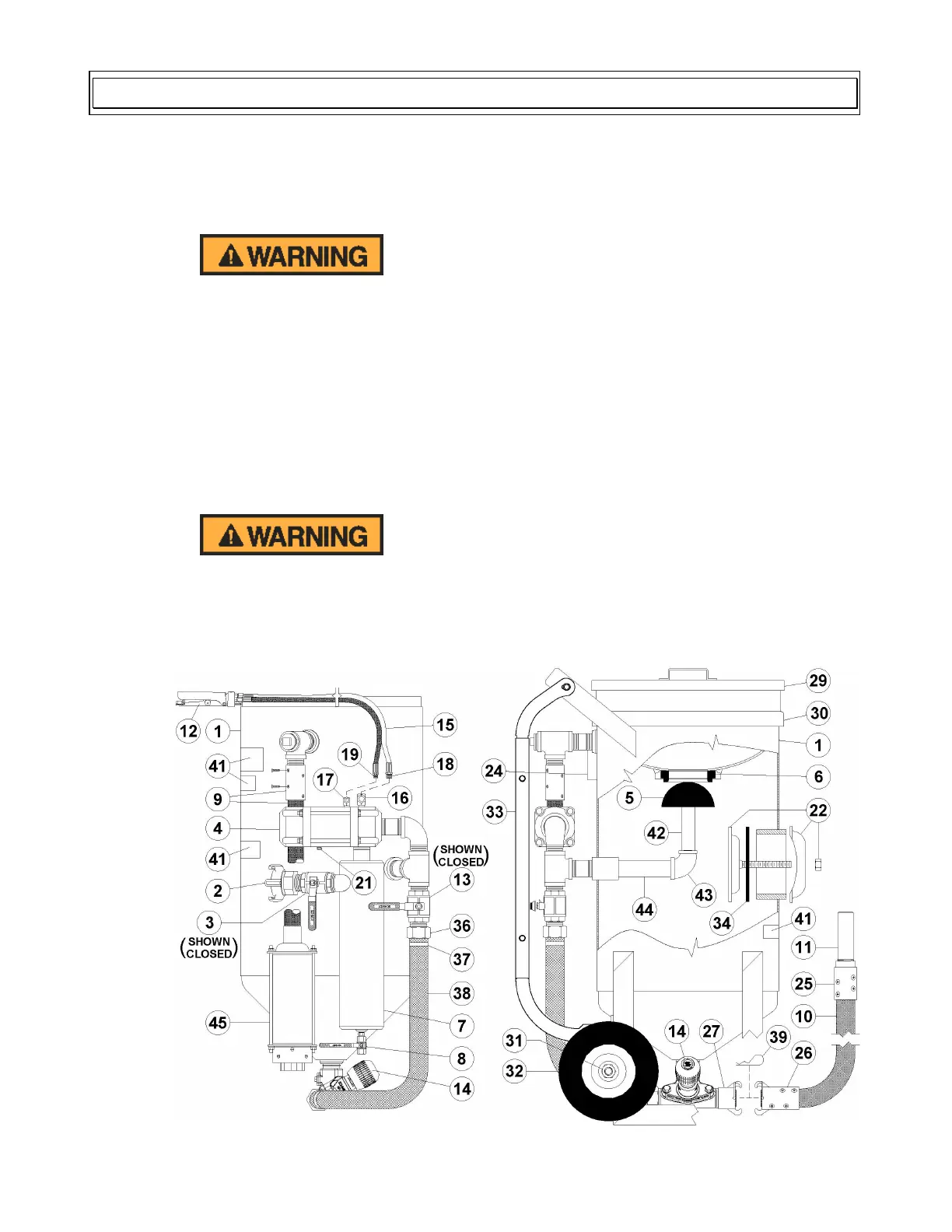

7.1.2. Remove the vessel lid (#29) and screen (#30) to check that the popup (#5) has dropped

open. The open popup indicates that the blast vessel is depressurized. See Figure 7.1.

7.1.3. Fill the blaster with dry abrasive though the abrasive inlet (#6). Pass recycled abrasive

through the screen (#30) to remove trash. Do not over-fill the blast vessel. An excessive

amount of abrasive piled above the popup (#5) after the blast vessel is full may prevent

the popup from sealing properly.

Pinch point hazard. Vessel pressurization will close the popup. Keep hands and fingers

away from popup. Disconnect air supply prior to performing popup maintenance.

7.1.4. After completing all the pre-operation procedures in Sections 6.0 and 7.1 pressurize the

abrasive blast vessel per Section 7.2, and then check the popup for leaks. Periodically

check the popup for leaks thereafter.

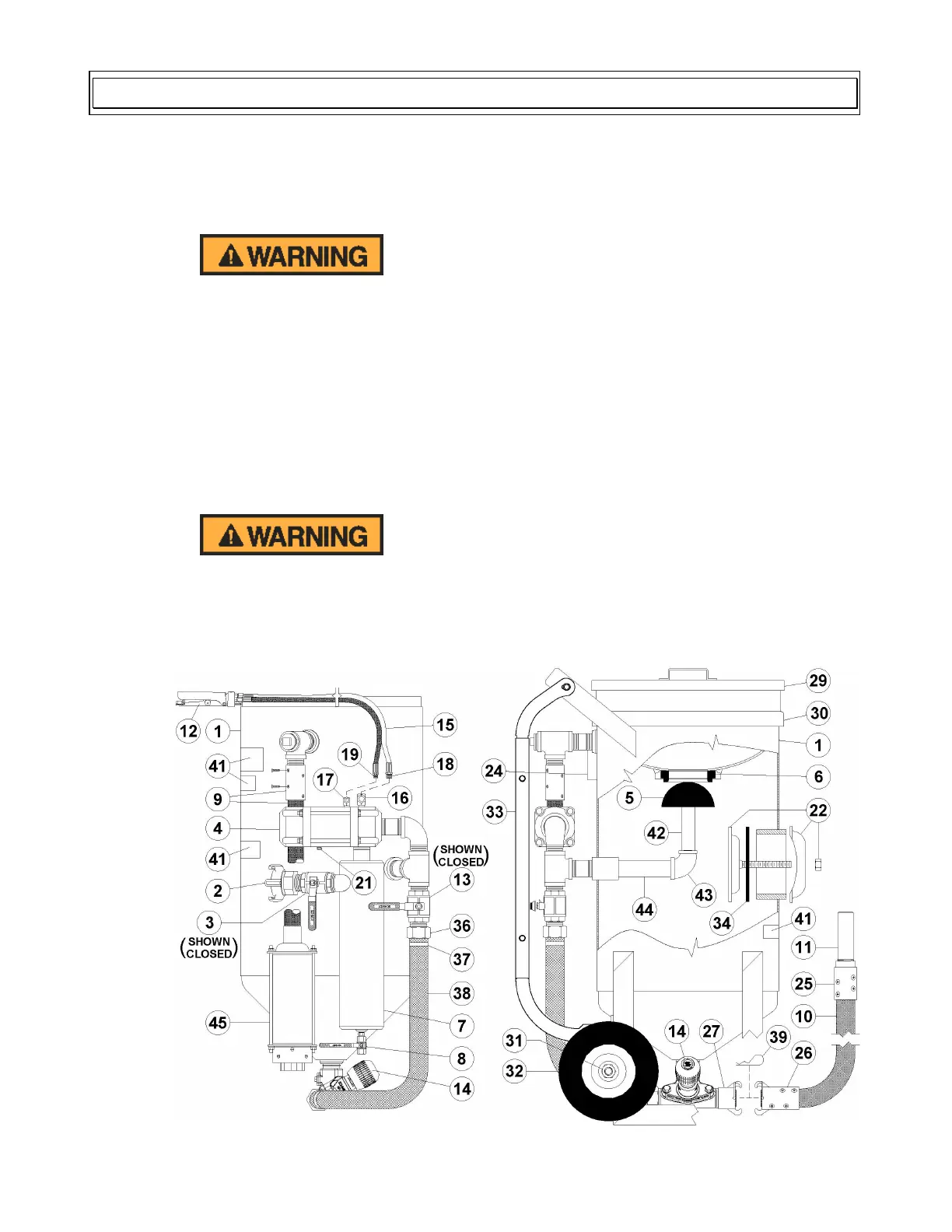

Figure 7.1 – MV3 Valve Abrasive Blaster with pneumatic blast controls

7.0 Operating Instructions

Loading...

Loading...