Copyright © 2021 Axxiom Manufacturing, Inc.

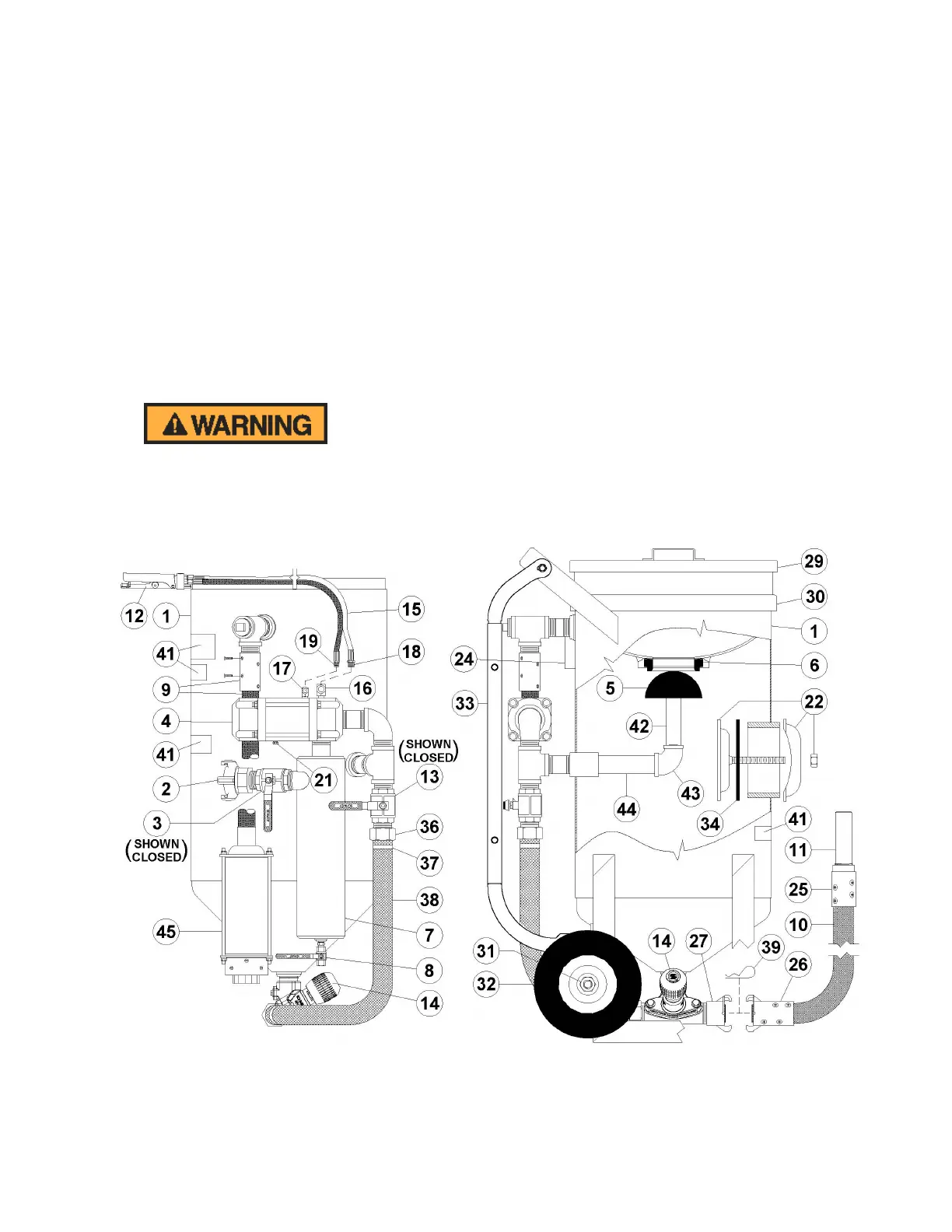

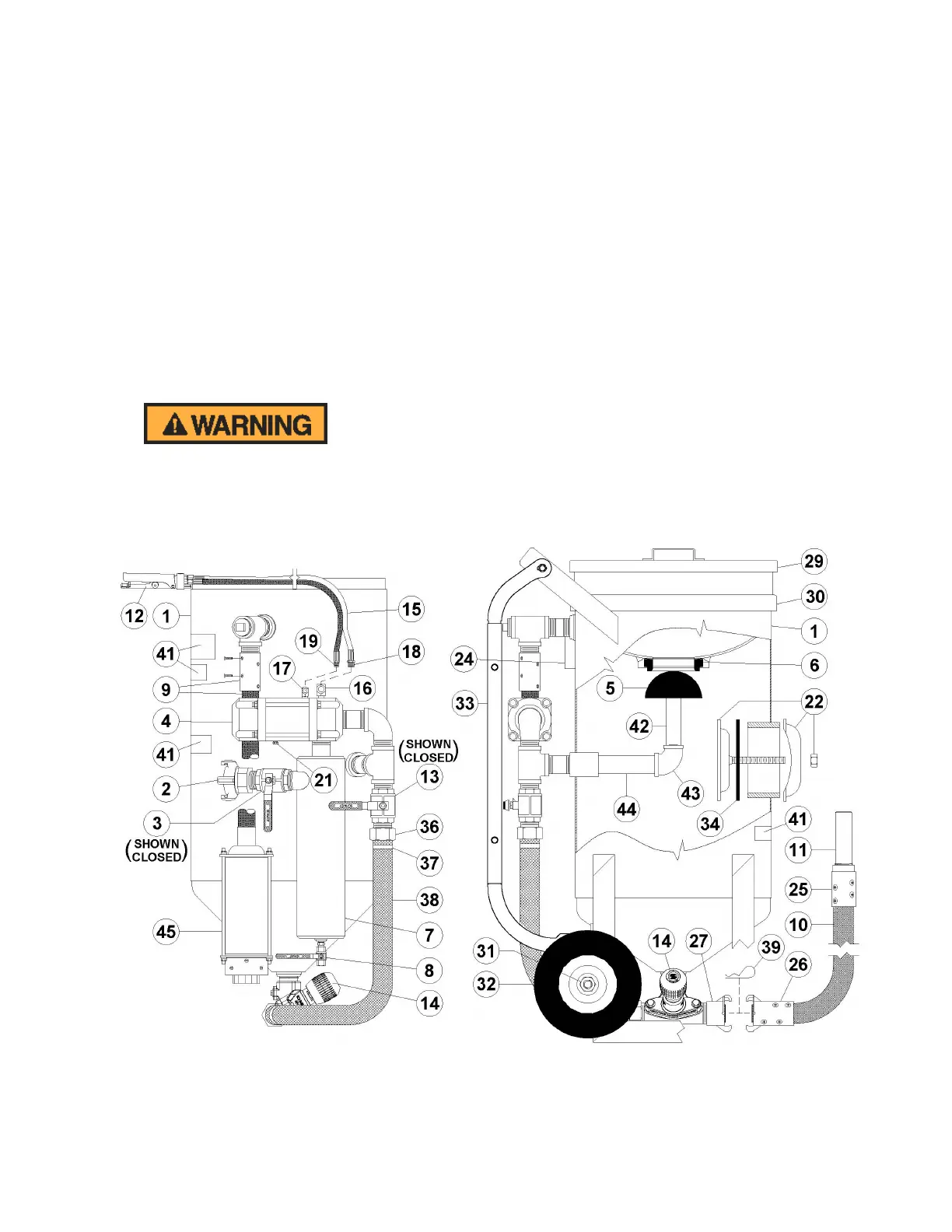

5.16 Volumetric Blowdown Suppression System II (patent pending)

The Volumetric Blowdown Suppression (VBS II) System (#45) is designed to reduce the noise

level and eliminate floor damage caused by the ComboValve® blowdown exhaust air. The

VBS II attaches to the end of blowdown hose assembly (#9) and is supported by a bracket that

attaches to the ComboValve. The VBS II System changes the characteristics of the blowdown

exhaust air as it flows through. First, the VBS II reduces the noise level of the blowdown air by

internal sound absorption. Secondly, the VBS II system diffuses and reduces the velocity of the

blowdown air and abrasive mixture. The VBS II self-cleaning urethane exhaust cap design

absorbs the abrasive impact to reduce wear on the internal components and prevents clogging.

The standard blowdown hose must be shortened to 14-1/2” to accommodate the VBS II System.

Note: The VBS is standard on MV3 / ComboValve package blasters manufactured after June

2011 (except for 1.5cf). Conversion kits are available for field addition of the VBS II System.

Consult Axxiom Manufacturing, Inc. or an authorized Schmidt distributor.

Airborne particles and loud noise hazards from blowdown exhaust air can cause serious injury

and loss of hearing. Wear approved eye and ear protection. Stay clear of exhaust air path. DO

NOT place hands or other body parts in the exhaust air path. Make sure no personnel are in the

exhaust air path.

Figure 5.8 – Typical MV3 Blaster with the VBS II System

Loading...

Loading...