Copyright © 2021 Axxiom Manufacturing, Inc.

6.1.6. Verify that all required personal protective equipment is available for each operator and

in good operating condition (safety glasses, safety shoes, ear plugs, gloves, airline filter,

respirator, & carbon monoxide monitor). Critical: Adhere to all local, state, and federal

regulations including, but not limited to, OSHA (Occupational Health and Safety

Administration). Pay close attention to requirements regarding breathing air quality.

When an oil-lubricated air compressor is used, additional requirements for a high

temperature alarm and/or a carbon monoxide monitor become necessary. See Sections

3.9 and 3.10.

Failure to use personal protective equipment could result in serious injury or death.

6.1.7. Hose clamp the deadman (#12) to the blast hose assembly in a comfortable position

behind the nozzle holder (#25).

6.1.8. Wire tie the twinline hose (#15) or electric deadman extension cords to the blast hose

assembly (#10).

6.1.9. Screw nozzle (#11) into the nozzle holder (#25) at end of the blast hose assembly (#10).

6.1.10. Connect the blast hose coupling (#26) to the threaded coupling (#27) on the abrasive

metering valve (#14). Then install safety pins (#39) and a hose whip check (#40) to

protect against accidental disconnections during operation. See Sections 5.12, and 8.7.

Failure to install safety pins on all blast hose couplings can result in hose disconnects

and could result in serious injury or death. See Sections 5.12 and 8.7.

6.1.11. Connect the twinline hose quick disconnects (#18 & #19) or the electric deadman

extension cord to the mating disconnect(s) (#16 & #17) on the abrasive blaster piping.

6.1.12. Close the air inlet ball valve (#3).

6.1.13. Connect a 150psi rated (minimum) air supply hose to the air inlet crowfoot (#2) and

install safety pins (#39) and a hose whip check (#40) to protect against accidental

disconnections during operation. See Sections 5.12 and 8.7.

Failure to install safety pins on all air hose couplings can result in hose disconnects and

could result in serious injury or death. See Sections 5.12 and 8.7.

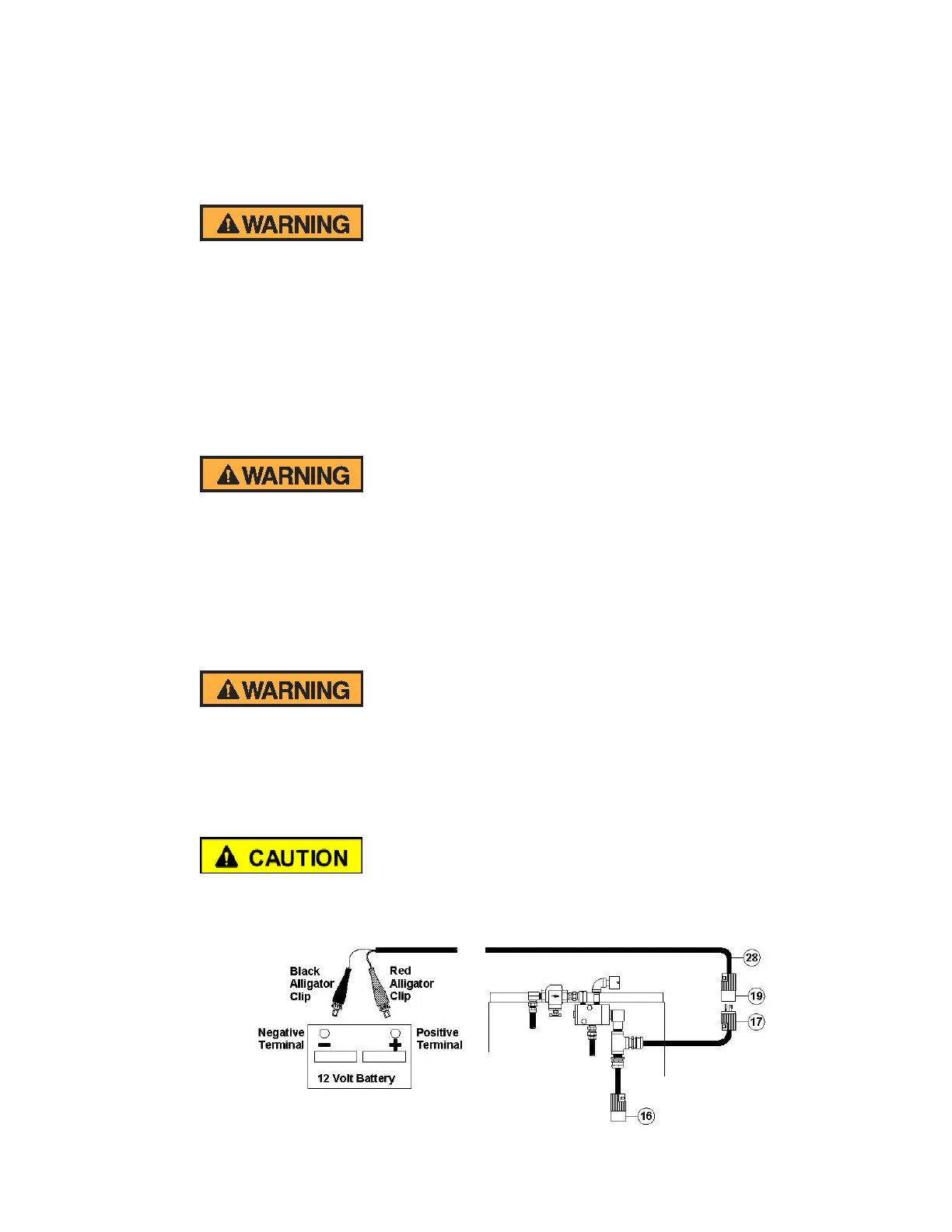

6.1.14. The following steps apply only to abrasive blasters with electric systems. Connect the

electric power cord (#28) to the blaster junction tee connector (#17).

6.1.15. Connect the electric power cord alligator clips (#28) to the air compressor battery

terminals or to another 12Vdc power source. See Figure 6.1.

Electric shock hazard. Abrasive blasters with electric deadman blast control systems

must operate on low voltage supply (12-24 volts). To minimize shock hazard only use

low voltage sources and use caution when connecting the power to the abrasive blaster.

See Section 3.7.

Figure 6.1 – Electric power connection

Loading...

Loading...