OPERATION

FX-520 06/16 Operation Section 4-19

© 2016 Alamo Group Inc.

OPERATION

8.2 Implement Pre-Operation Inspection/Service

Before each use, a pre-operation inspection and service of the implement and tractor must be performed. This

includes routine maintenance and scheduled lubrication, inspecting that all safety devices are equipped and

functional, and performing needed repairs. Do not operate the implement and tractor if the pre-operation

inspection reveals any condition affecting safe operation. Perform repairs and replacement of damaged and

missing parts as soon as noticed. By performing a thorough pre-operation inspection and service, valuable

down time and repair cost can be avoided.

8.1 Tractor Pre-Operation Inspection/Service

Refer to the tractor operator’s manual to ensure a

complete pre-operation inspection and scheduled

service is performed according to the

manufacturers recommendations. The following

are some of the items that require daily service and

inspection:

• Tire condition/air pressure

• Wheel lug bolts

• Steering linkage

• PTO shield

• SMV sign is clean and visible

• Tractor’s lights are clean and functional

• Tractor Seat belt is in good condition

• Tractor ROPS is in good condition

• ROPS is in the raised position

• No tractor oil leaks

• Radiator free of debris

• Engine oil level and condition

• Engine coolant level and condition

• Power brake fluid level

• Power steering fluid level

• Fuel condition and level

• Sufficient lubrication at all lube points

• Air filter condition OPS-U-0030

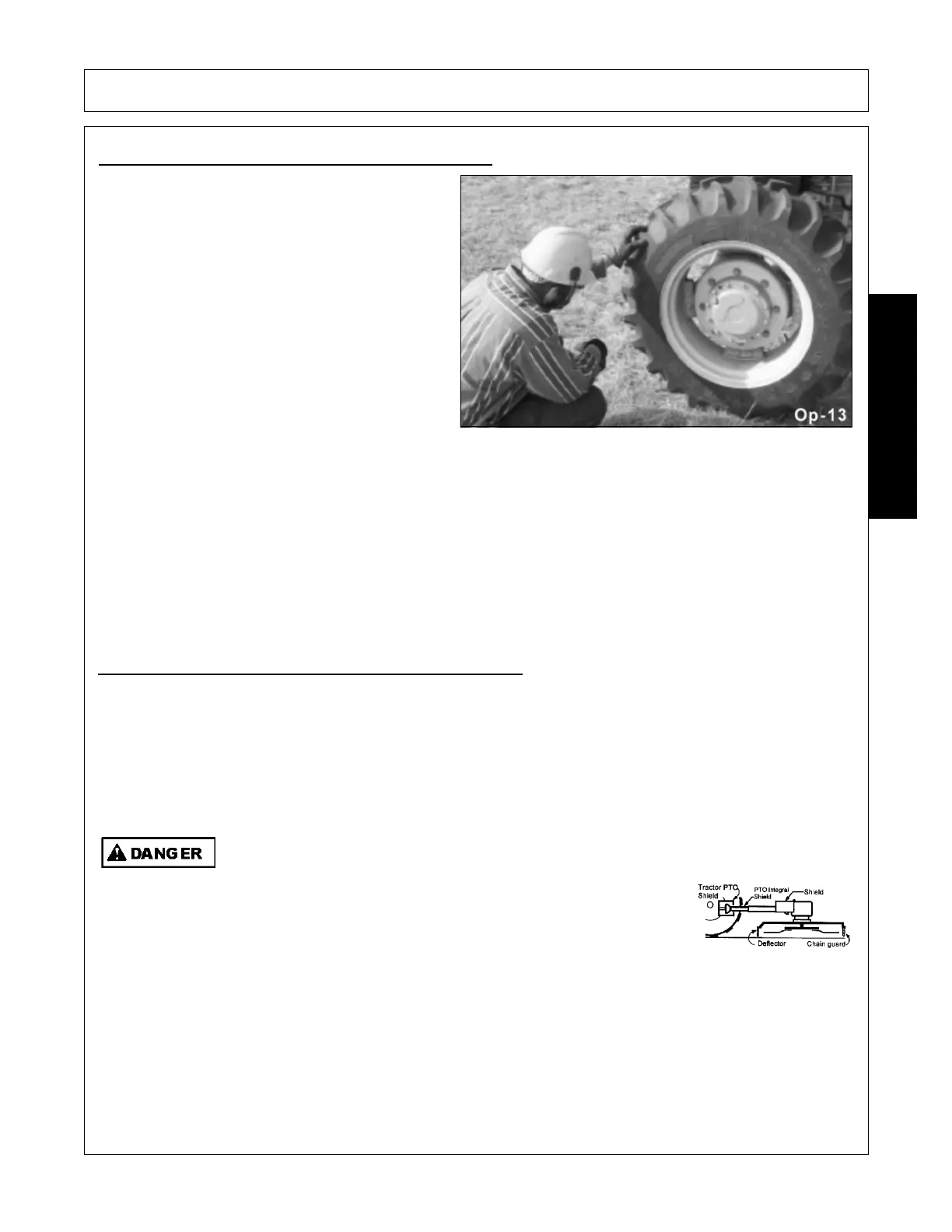

All Safety Shields, Guards and Safety devices including (but not

limited to) - the Deflectors, Chain Guards, Steel Guards, Gearbox

Shields, PTO integral shields, and Retractable Door Shields should

be used and maintained in good working condition. All safety

devices should be inspected carefully at least daily for missing or

broken components. Missing, broken, or worn items must be

replaced at once to reduce the possibility of injury or death from

thrown objects, entanglement, or blade contact.

(SGM-3)

Loading...

Loading...