113

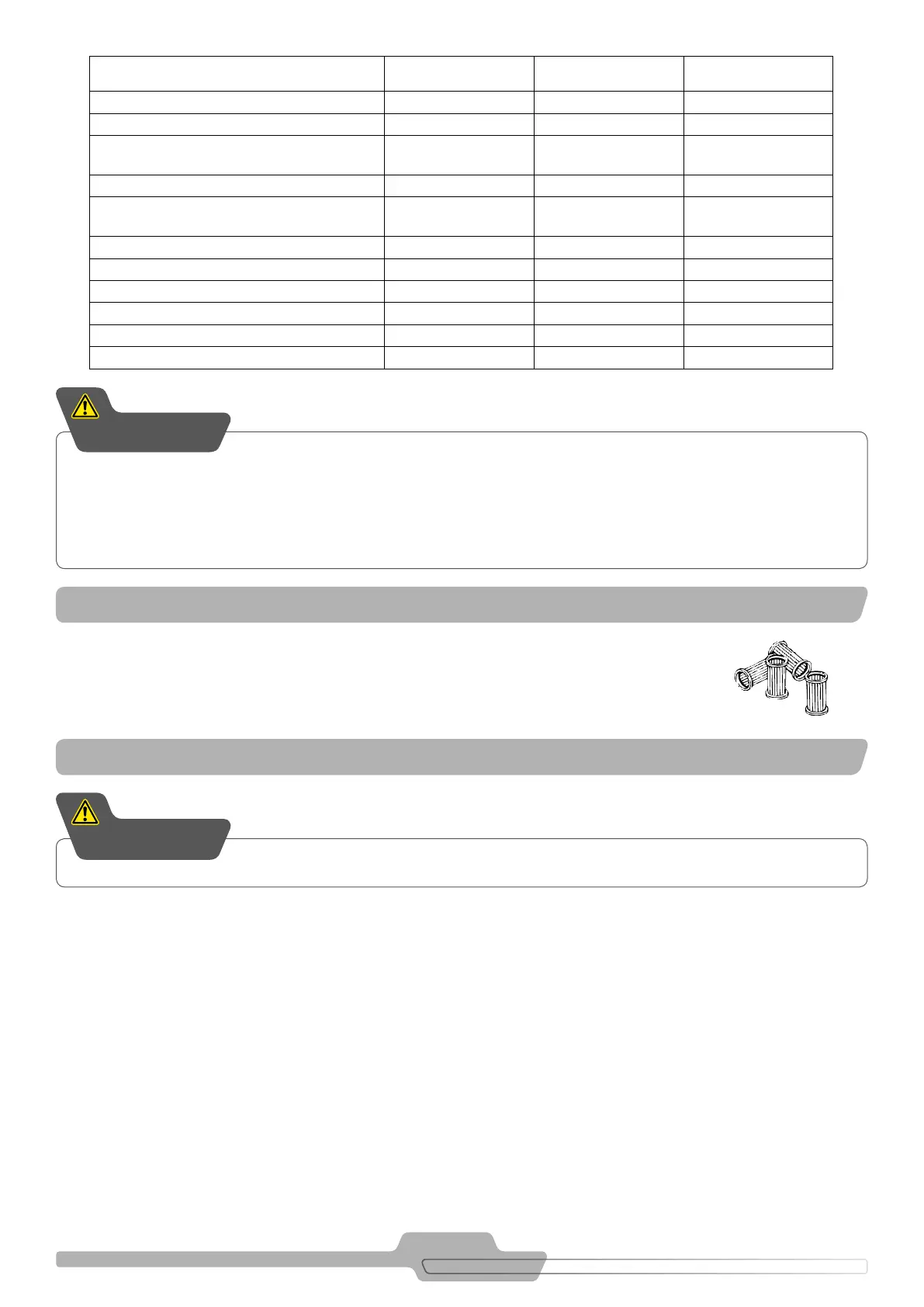

Procedure Daily

Every

1000 hours*

When required

Annually

Check the digital controller temperature X

Check the fan operation X

Check the dryer drain and the coalescent

filter operation

X

Clean the drain system X X

Check the display on the blockage of the

coalescent filters

X X

Change the coalescent filters X (1)

Check the voltage of electricity system X

Check the electrical current X

Clean the condenser X (2) X

Inspection performed by Technician X

Clean the compressed air circuit X

TABLE 14.1

When the SRS - Air Dryer coalescent filters have been operated, installed by customer, in compliance to current

local standards; they must be disposed of.

See additional guidance of “Recommended Environmental Guidance”.

15. REMOVING MAINTENANCE PARTS - DISPOSAL

16. CORRECTIVE MAINTENANCE

Check the dryer drain and the coalescent filter operation.

(1) For Coalescent Filters installed in the compressed air network (in compliance with manufacturer

instructions).

(2) The cleaning period can be anticipated or prolonged based on the existent contaminants in the SRS - Air Dryer equipment installation

location conditions.

* Use as a reference the scroll compressor hour meter whenever installed together with piston compressors to monitor maintenance

procedures.

IMPORTANT

To guarantee the SAFETY and RELIABILITY of the product, the repairs, maintenance and adjustments must

be performed through the nearest SCHULZ AUTHORIZED DEALER, which always uses genuine parts.

ATTENTION

Loading...

Loading...