86

1. Electronic Controller

2. On/Off

3. Low pressure - switch

4. Fan control switch

5. High pressure - switch

6. Hot gas “by-pass” valve

7. Refrigerant filter

8. Refrigeration compressor

9. Contactor

10. Breaker Switch

11. Motor fan(s)

12. Needle valve

13. Purge solenoid valve

14. Compress air outlet without humidity

15. Compress air outlet with humidity

16. Condensation outlet

17. Electrical cable entrance

18. Heat exchanger

19. Condenser

20. Expansion device

SRS – Air Dryers are supplied with feminine flanges, gauges as shown on Table 6.1 - Technical Specifications.

Do not use a reduction fitting on the outlet of the SRS - Air Dryer, or install undersized line filter(s) so that there is no loss of pressure near

the air production source. Whenever possible install “Y” connectors instead of “T” connectors and long-radius bend connectors.

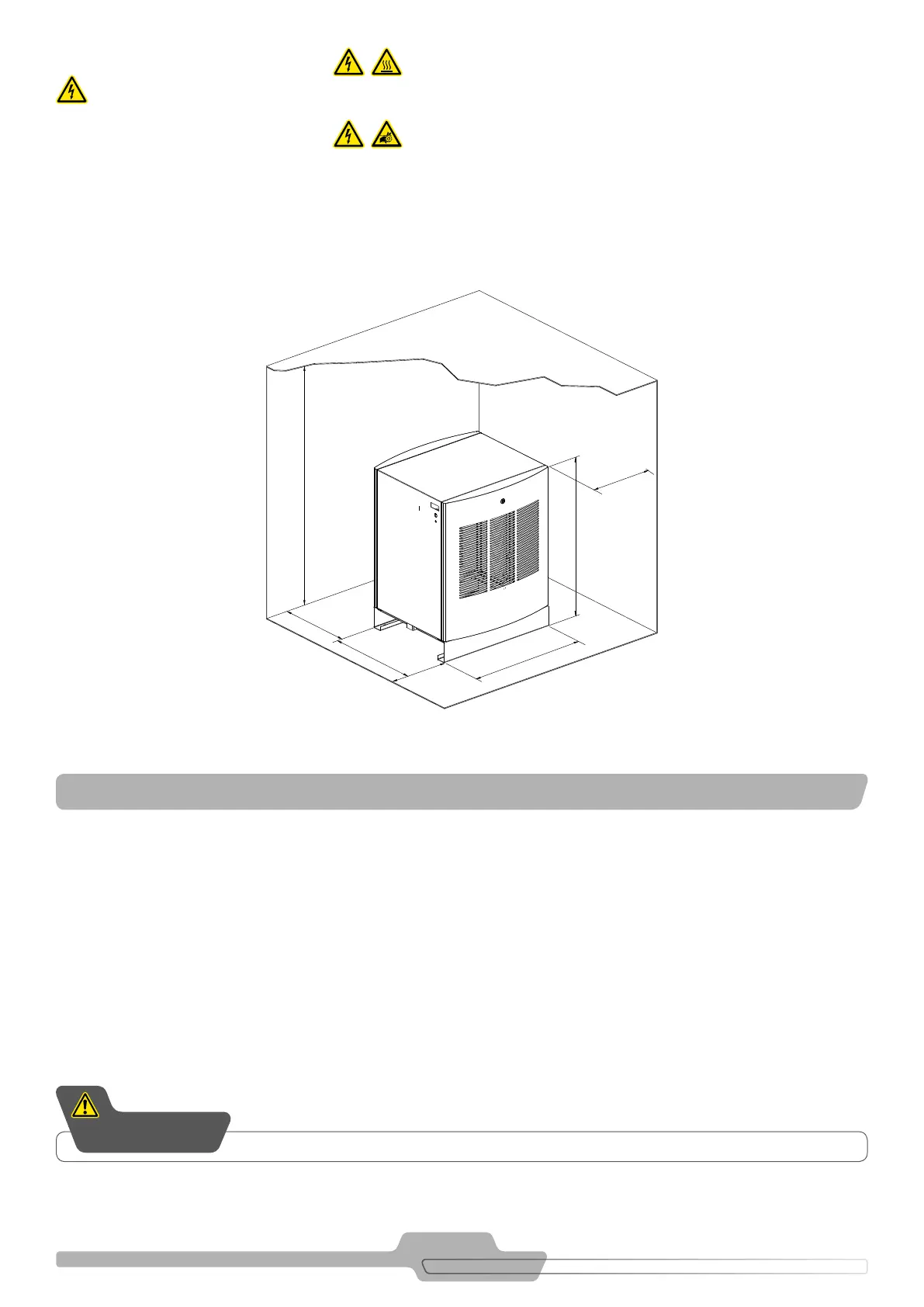

FIGURE 8.3 – MINIMUM DISTANCES FROM WALL AND CEILING (OR ANY OTHER OBSTACLE) THE PRODUCT MUST BE INSTALLED TO

GUARANTEE NECESSARY VENTILATION CONDITIONS

1 m

1 m

3 m

1 m

c

a

b

1. Location

The compressor must be installed in an engine room according to NR13 of MTb, in a roofed area that is well ventilated, free from dust, toxic

gases, humidity or pollution of any kind. In order to reduce the excess of noise, a soundproofing project must be taken into consideration.

The maximum recommended room temperature for operation is 38°C. The access to the equipment must be prohibited for people who are

unfamiliar with the use. If the room temperature is over that, it is necessary to use the flow correction table. This applies factors which

help to find out the corrected discharge the dryer is able to process. The use of exhaust fans is also recommended, cooling ducts, or other

means to provide a decrease in temperature. Then, in the case of Alternating Piston Compressors, it is strongly recommended for the dryer

to be in a well-ventilated environment and as far as possible from the place where the air compressors are to be installed. In even higher

temperatures, (room temperature over 40°C) operating with Piston Compressors, the next higher discharge capacity of dryer model must be

used or get in touch with an accredited Schulz Authorized-Technical/Distributor for this equipment.

If the room temperature is near or less than 5°C, the SRS - Air Dryer is not recommended, as heating is required for the machine room and the

entire compressed air pipeline for temperatures around or over 10°C. The presence of contamination agents (dust, fibers, etc.) suspended

in the air can cause premature obstruction of the condenser (See the chapter on Preventive Maintenance).

2. Placement

Notice the recommended distance in Illustration 8.3, away from any obstacle to avoid harming the operation and at the same time facilita-

ting preventive maintenance of the SRS - Air Dryer.

9. INSTALLATION

Do not install the air dryer in chemically contaminated areas.

ATTENTION

Loading...

Loading...