81

Operation

SP 500 / 750-15 / 750-18 / 1000 / 1250 Operation Manual

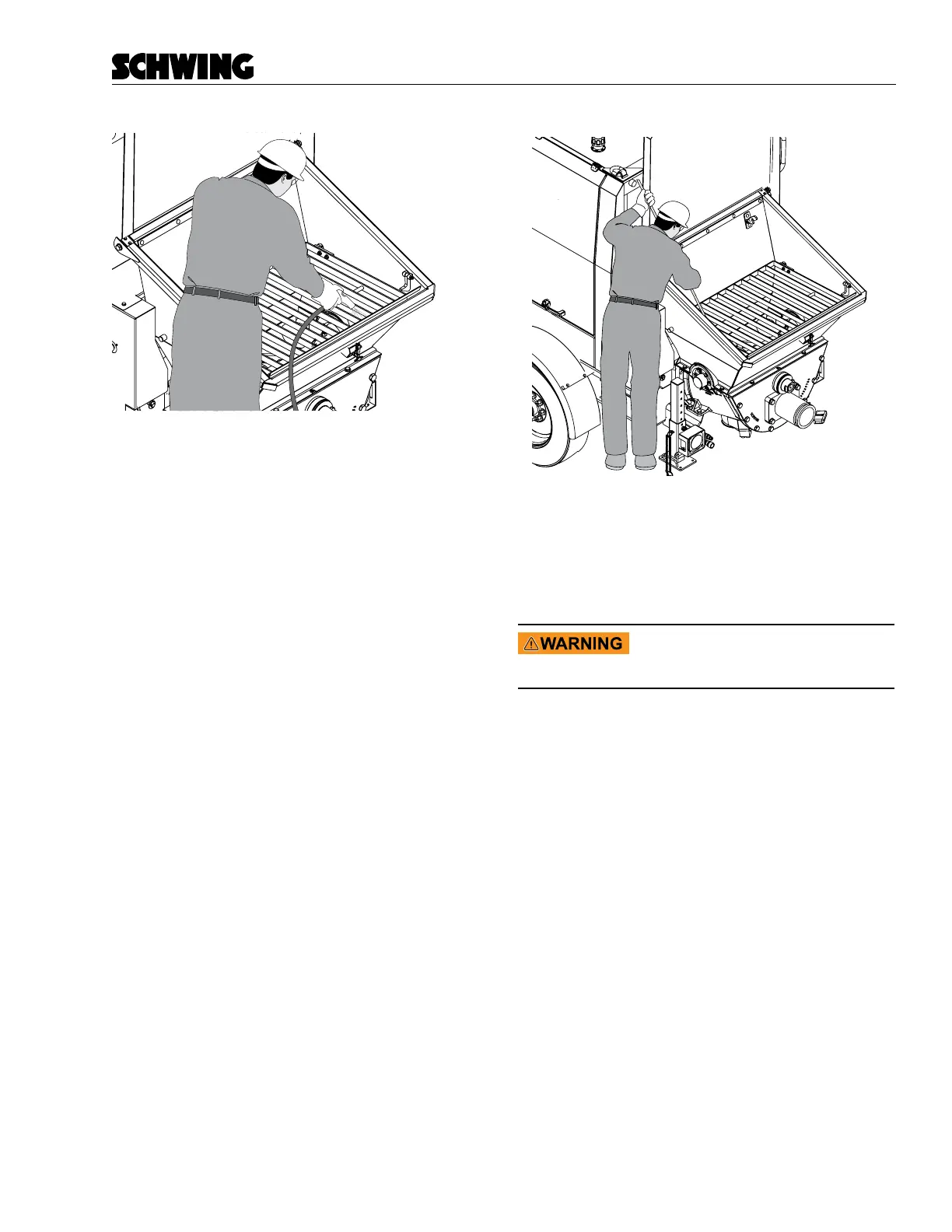

Figure 23

Clean Agitator and Hopper

• Keep the agitator turning until you have sprayed

the blades clean (Figure 23). Wash the material

from the hopper out of the cleanout door on the

bottom.

• Stop the agitator from turning with the agitator

switch on the control panel. Do not proceed to the

next step until this is done. Visually conrm that

the agitator has stopped by looking into the hop-

per.

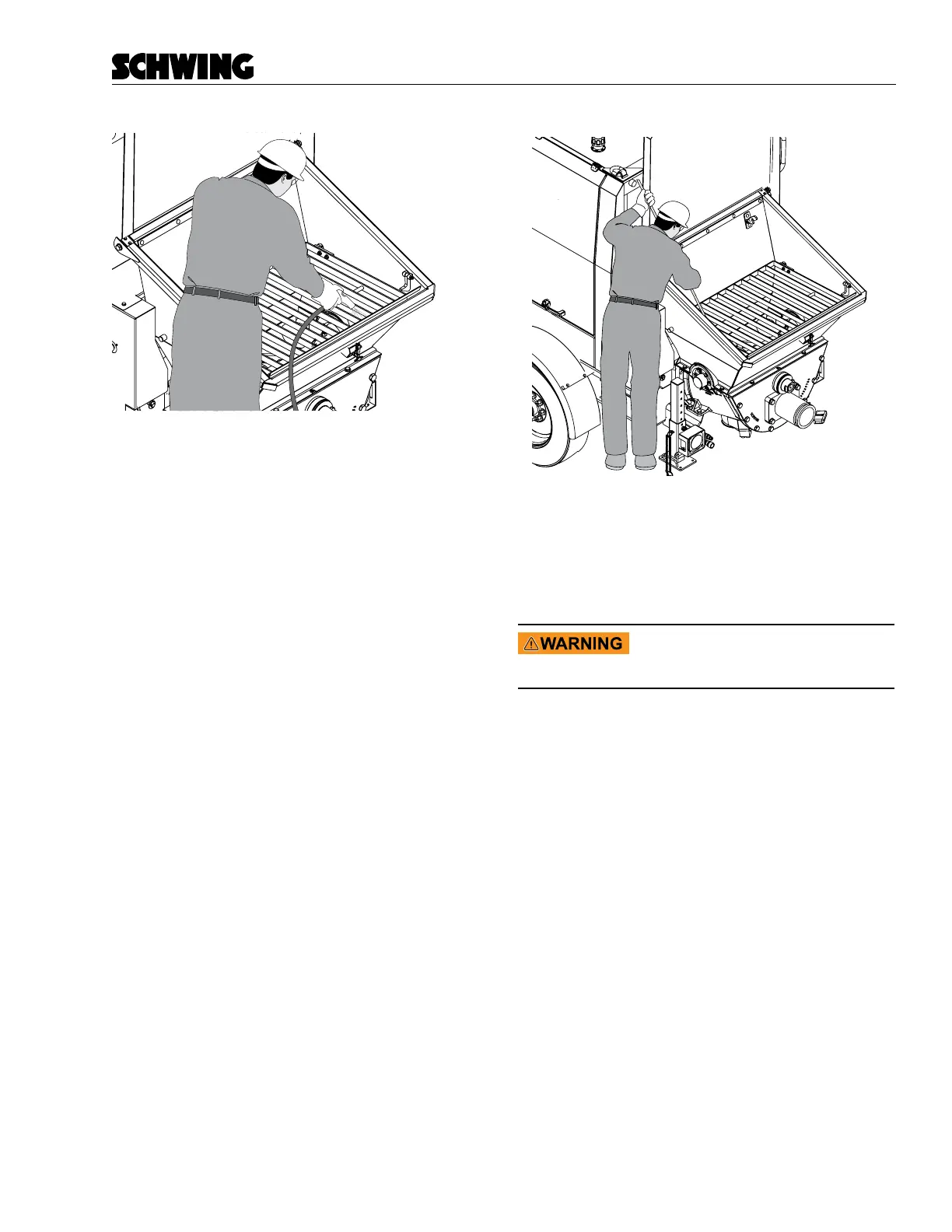

• Poke any material that has set in the corners of

your hopper with a piece of rebar or another sti,

long bar (Figure 24). Do not remove the hopper

grate for this cleanout procedure. This procedure

must be done with the hopper grate in place. Do

not spend too much time on this procedure, or

the concrete will have time to set up in the Rock

Valve and material cylinders.

SWG98n188.eps

Figure 24

Remove Hardened Concrete From Hopper

If concrete in the hopper has completely set, you will

need to use a chipping hammer or another power tool to

clean it. The grate is removable for this purpose.

Amputation/crushing hazard. Never

work inside the hopper without dis-

abling the hydraulic system.

For safety reasons, return to your shop before you re-

move any concrete that has completely set. Once the

concrete has set, there is no advantage to chipping it

away at the job site.

Loading...

Loading...