82

Operation

SP 500 / 750-15 / 750-18 / 1000 / 1250 Operation Manual

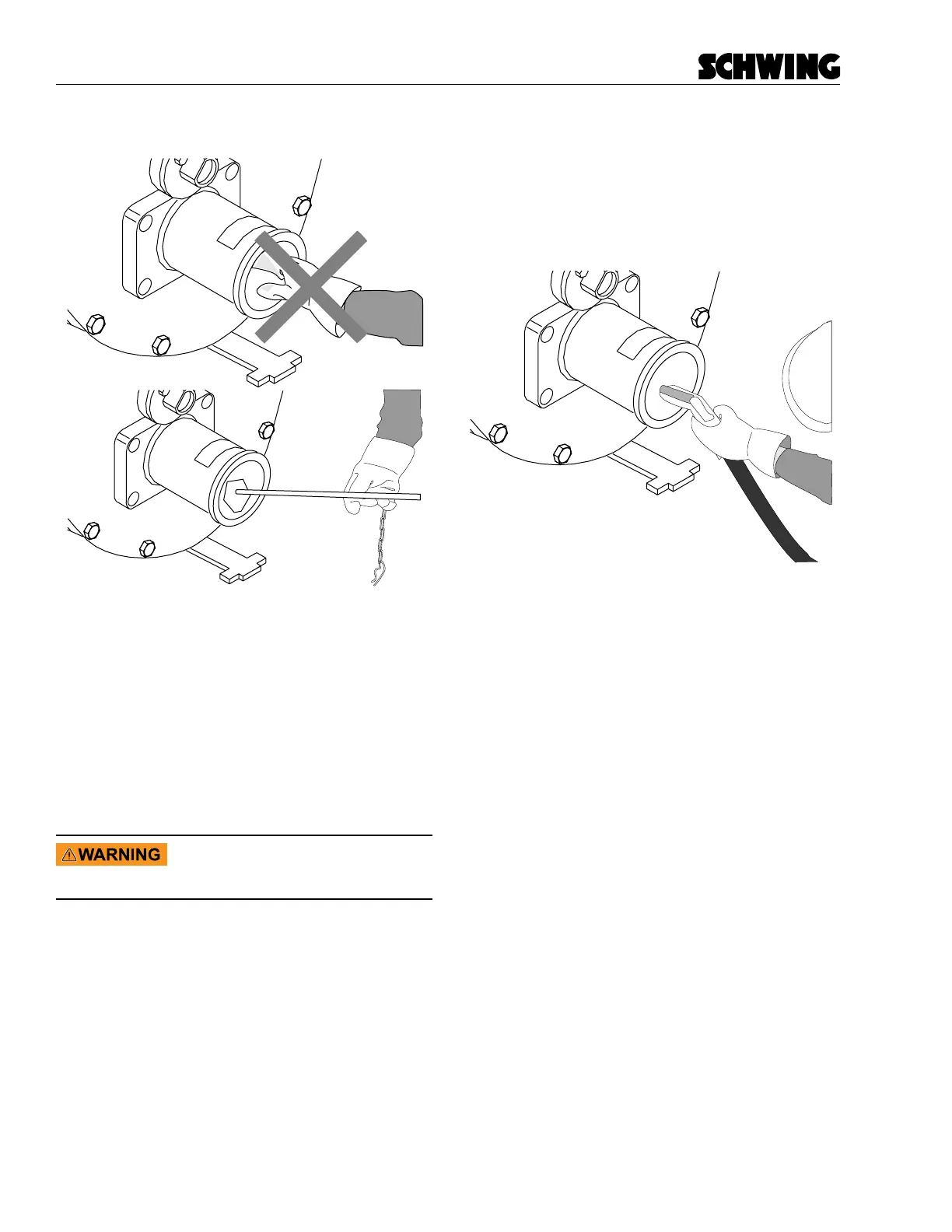

Cleaning the Rock Valve

SWG98n190.eps

SWG98n189.eps

Figure 25

Rock Valve and Material Cylinder Cleanout

Once the hopper is clean, you should clean out the

Rock Valve and material cylinders. Before you begin

this step, bring the engine speed to an idle. Stroke the

concrete pump one complete stroke in reverse, until the

Rock Valve shifts across, then stop the pump. This step

ensures that the exposed material cylinder will have the

rubber ram extended to the end, thereby eliminating the

need to pull material from deep inside the cylinder.

Amputation hazard. Stop pump be-

fore cleaning the Rock Valve and

hopper.

Be sure that the concrete pump is turned to the OFF

position before proceeding. Using your cleanout rake,

pull any material from the exposed material cylinder, the

Rock Valve, and the outlet pipe (Figure 25).

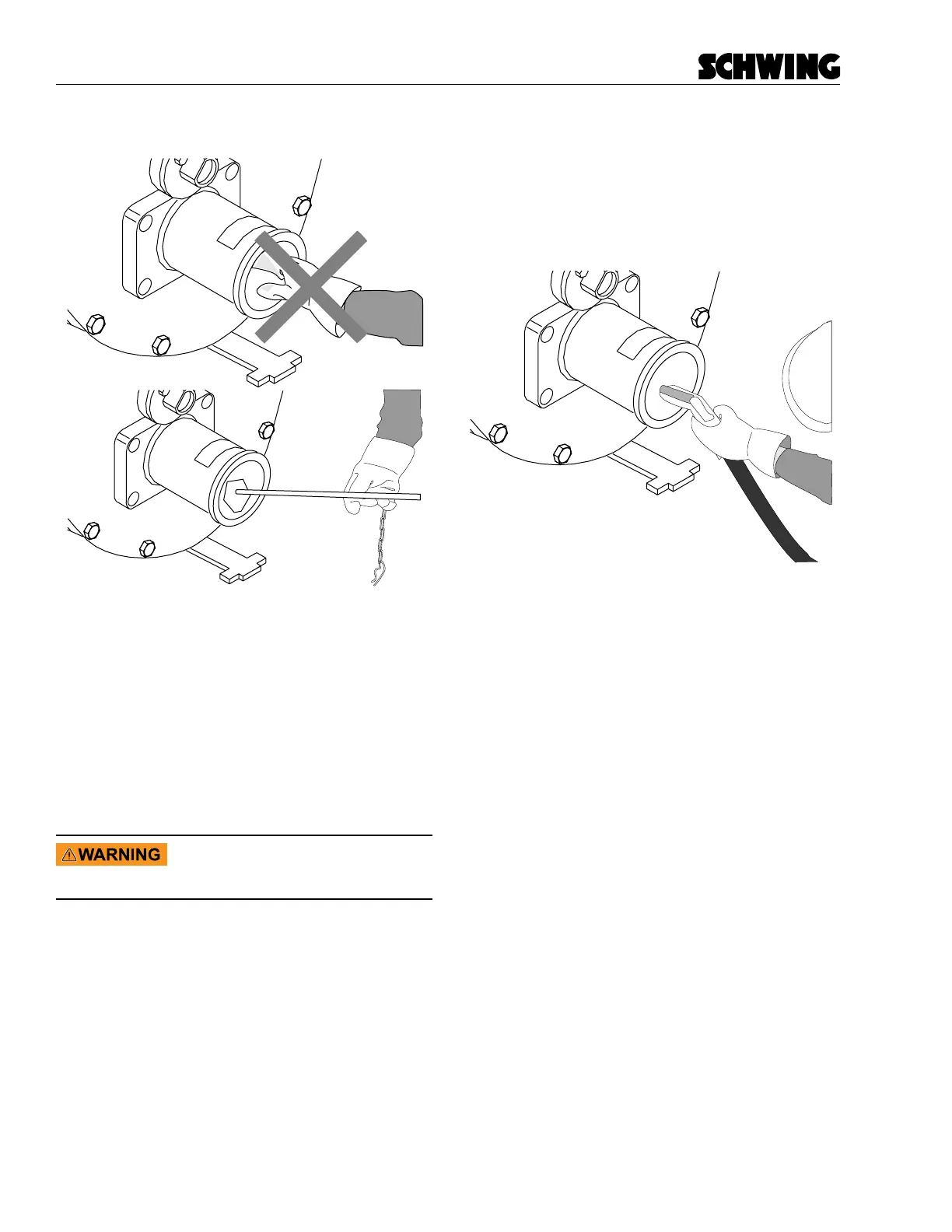

• Spray water into the opening, washing the end

of the rubber ram, the material cylinder, the Rock

Valve, and the outlet pipe (Figure 26). Continue

washing until the water that leaves the valve is

clear and clean. Visually inspect that no rocks,

sand, or clumps of concrete remain. If there is still

material, continue spraying water.

Figure 26

Spraying out Rock Valve

• Be sure that your rake and other tools are out of

the Rock Valve area, then cycle the machine in

reverse for one more stroke. This will expose the

opposite material cylinder, and completely extend

its rubber ram. Remove any loose material with

the clean out rake, then spray out the material cyl-

inder as in the previous step.

• By putting the pump into reverse mode, you are

sucking from the direction of the pipeline (which

is not connected during the cleanout procedure)

and pumping into the hopper. Because of this, you

may nd that you now have some material in the

bottom of the hopper again. You need to wash this

material out.

• Spray o the clamps, gaskets, and wedges.

• Close the hopper cleanout door, and reattach the

bungy cord, if used.

Loading...

Loading...