15

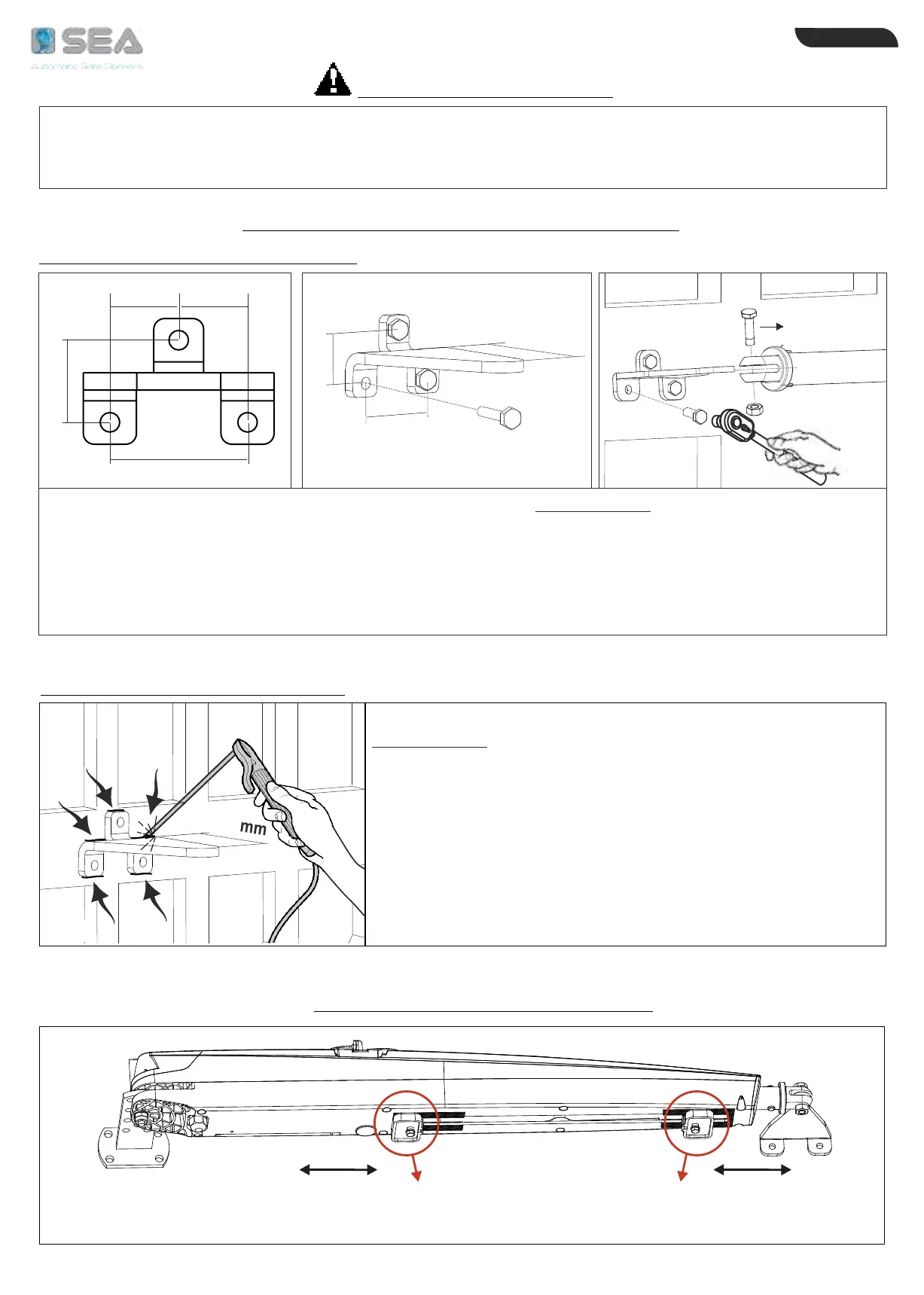

Fig. 18 Fig. 20

Fig. 19

110 mm

62 mm

38mm

62mm

= =

38mm

(A)

Once the operator has been mounted on the rear fixing bracket,

close the leaf and proceed as follows:

1) Release the operator keeping it always in a horizontal position

2) Weld the front fixing bracket on the gate operating on the points

indicated by the arrows (Fig. 21)

3) Insert the bracket into the housing pin on the operator (Fig. 20)

and tighten the «A» screw to max 8.5 Nm

CAUTION: Lubricate the pin with grease before installing the

front fixing bracket on the operator

1 - According to the gate type (wood, iron, aluminium) the front bracket can be welded or screwed

2 - Before mounting the rear and the front fixing brackets, lubricate with water repellent grease

3 - The operator must be mounted with the release facing upwards (Fig. 14)

PRELIMINARY NOTES

FRONT FIXING BRACKET MOUNTING

SCREWED FRONT FIXING BRACKET

WELDED FRONT FIXING BRACKET

Once the operator has been mounted on the rear fixing bracket, close the leaf and proceed as follows:

1) Release the operator keeping it always in a horizontal position

2) Screw the front fixing bracket onto the gate in correspondence of the holes made respecting the

dimensions as per Fig. 18 and Fig. 19

3) Insert the bracket into the housing pin on the operator (Fig. 20) and tighten the «A» screw to max 8.5 Nm

CAUTION: Lubricate the pin with grease before installing the front fixing bracket on the operator

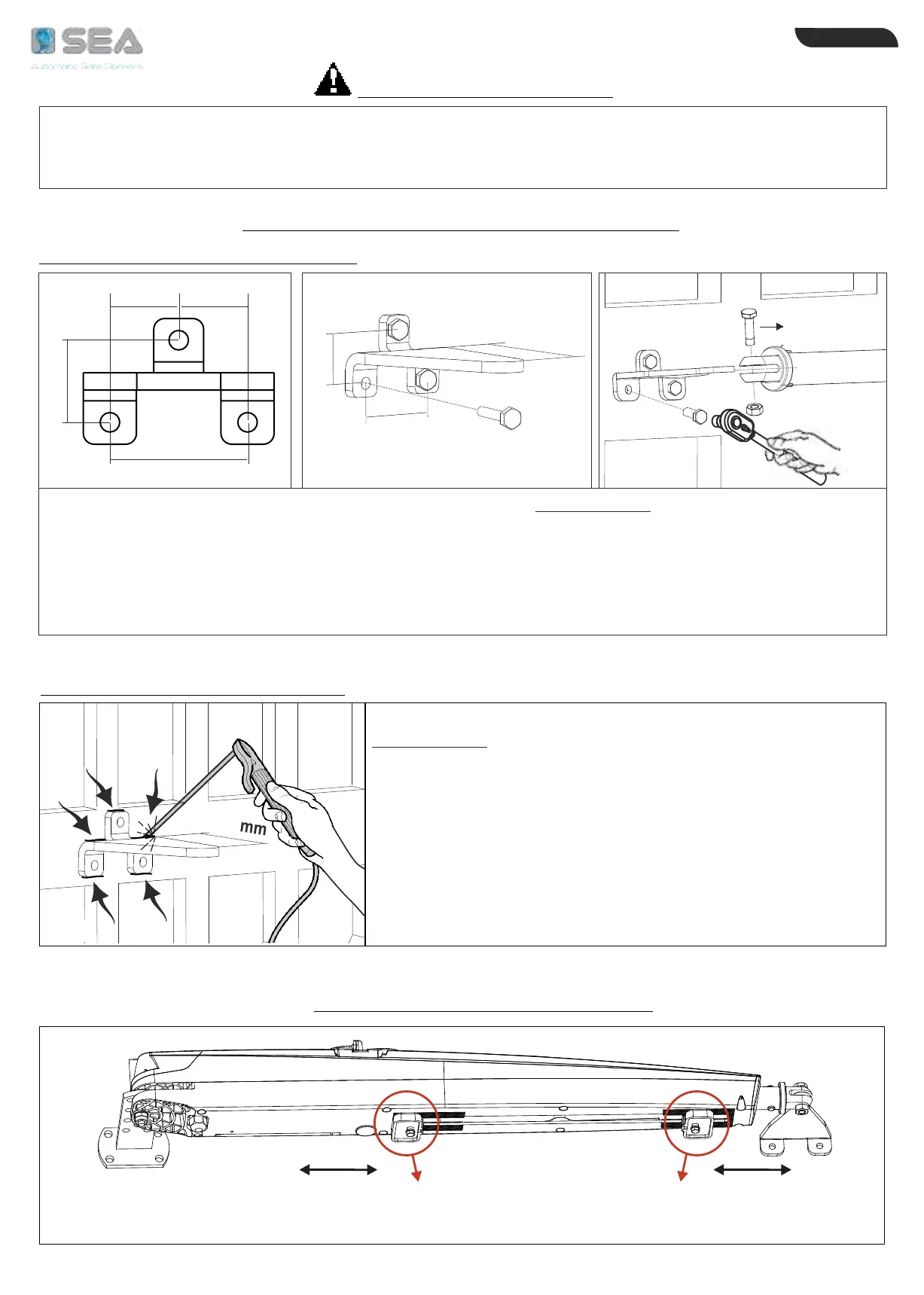

LIMIT SWITCH

IN CLOSING

30 mm

Max

1

10 mm

Fig. 21

MAGNETIC LIMIT SWITCHES

LIMIT SWITCH

IN OPENING

55 mm

Max

ENGLISH

International registered trademark n. 804888

Loading...

Loading...