16

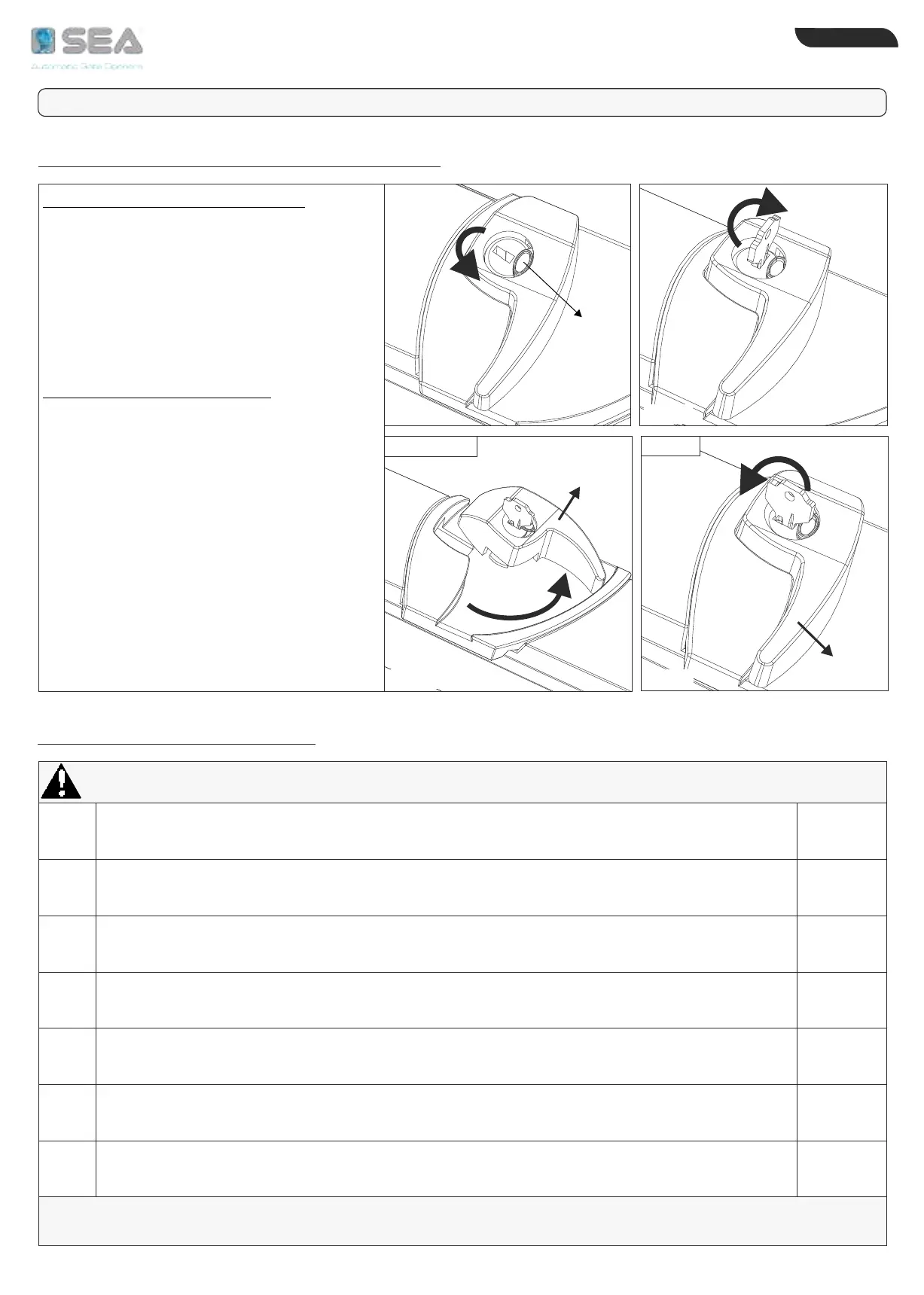

INTERNAL METAL RELEASE SYSTEM

TO RELEASE THE OPERATOR:

1) Turn counter-clockwise the lock

protection cover (Fig. 22)

2) Insert the key and turn of about 90°

clockwise (Fig. 23)

3) handleTurn the counter-clockwise to

release the operator (Fig. 24)

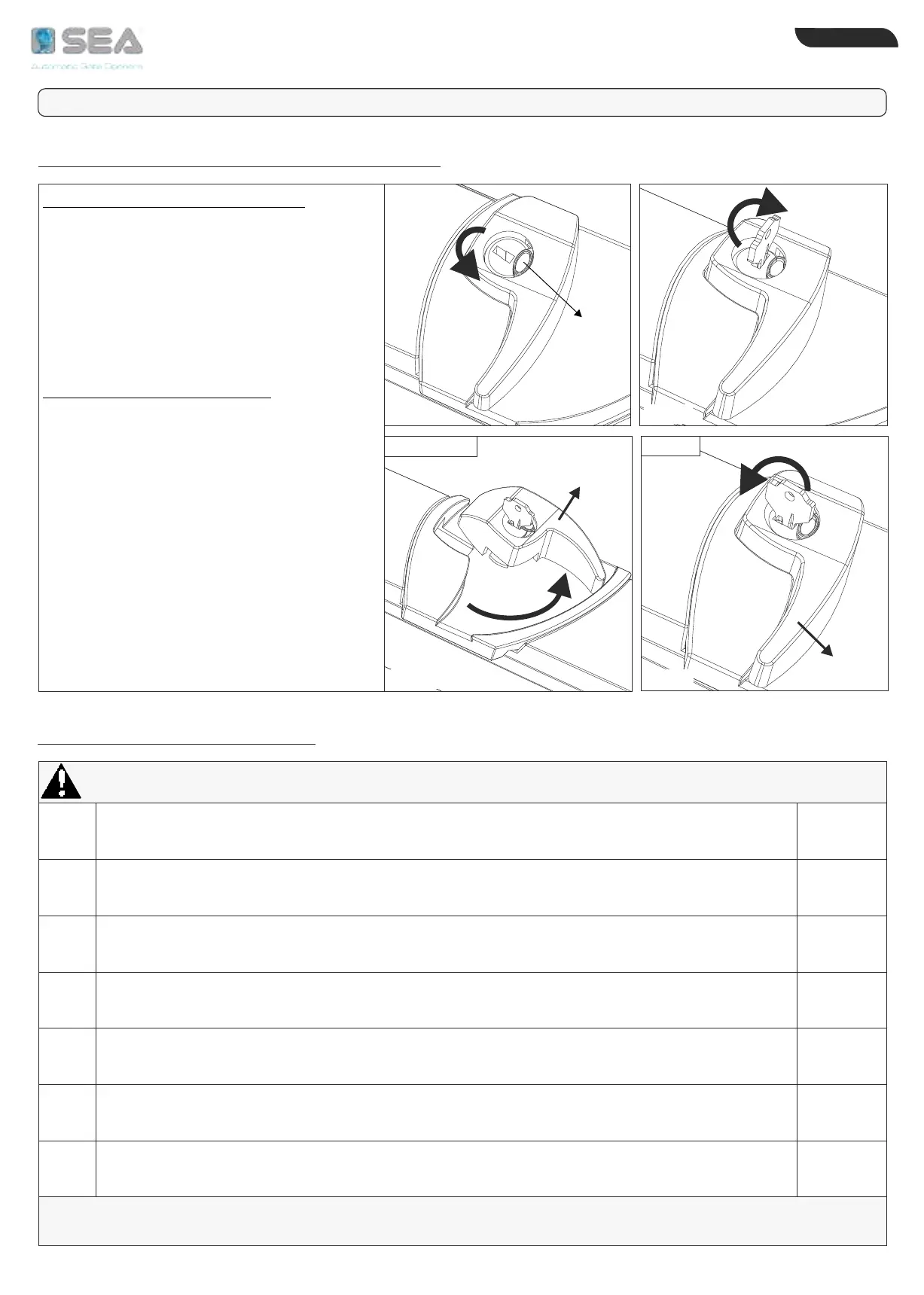

TO LOCK THE OPERATOR:

1) Turn the handle clockwise to revert it to

the initial position

2) Turn the key about 90° counter-

clockwise (Fig. 25)

3) After having relocked the operator, close

the lock protection cover to prevent

damages due to atmospheric agents

NOTE: for a proper operation of the

manual release it is recommended to

observe the current regulations

regarding the thrust force

90°

90°

Fig. 25

LOCK

RELEASE

Fig. 22

Fig. 23

Fig. 24

PERIODIC MAINTENANCE

TO THE ATTENTION OF THE TECHNICIAN AND THE END-USER

Handle

Handle

Lock

protection

cover

1

2

3

4

5

6

7

ALL OPERATIONS MUST BE MADE EXCLUSIVELY BY AN AUTHORIZED INSTALLER AND WHEN POWER SUPPLY IS OFF

AFTER THE PERIODICAL MAINTENANCE OPERATIONS IT IS NECESSARY TO REPEAT THE TEST OF THE

AUTOMATION AND ITS COMMISSIONING

YEARLY

YEARLY

YEARLY

YEARLY

YEARLY

YEARLY

YEARLY

Check the robustness and the stability of the gate, especially of the points of support

and/or the gate points of rotation (pivots)

Check the release system function

Check and grease the fixing pivots and the endless screw

Check the integrity of the connection cables

Verify the function and the conditions of the mechanical stops in opening and closing

Verify the good condition of all mechanism subject to stress

(as front and rear fixing brackets)

Check the function of all accessories, in particular of all safety devices

ENGLISH

International registered trademark n. 804888

Loading...

Loading...