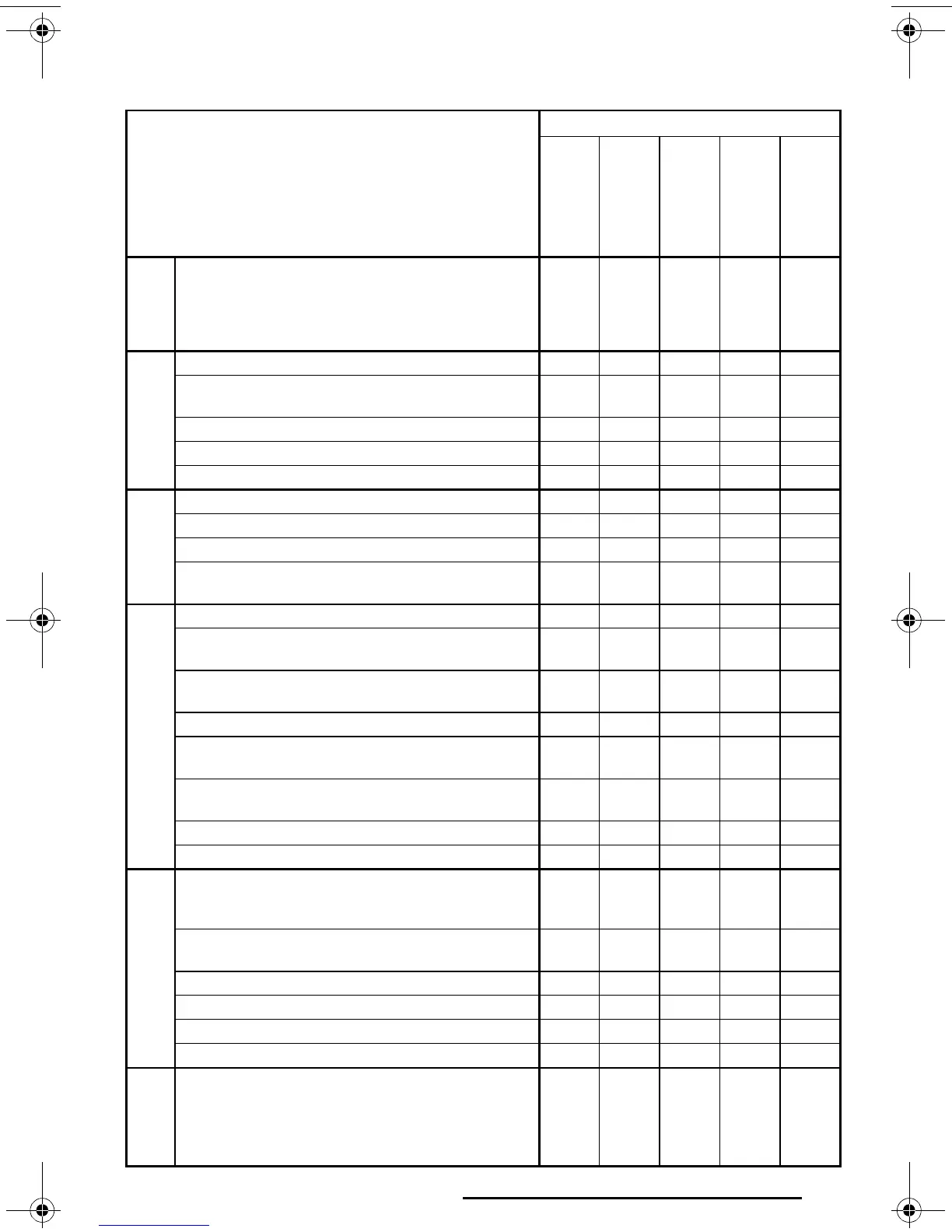

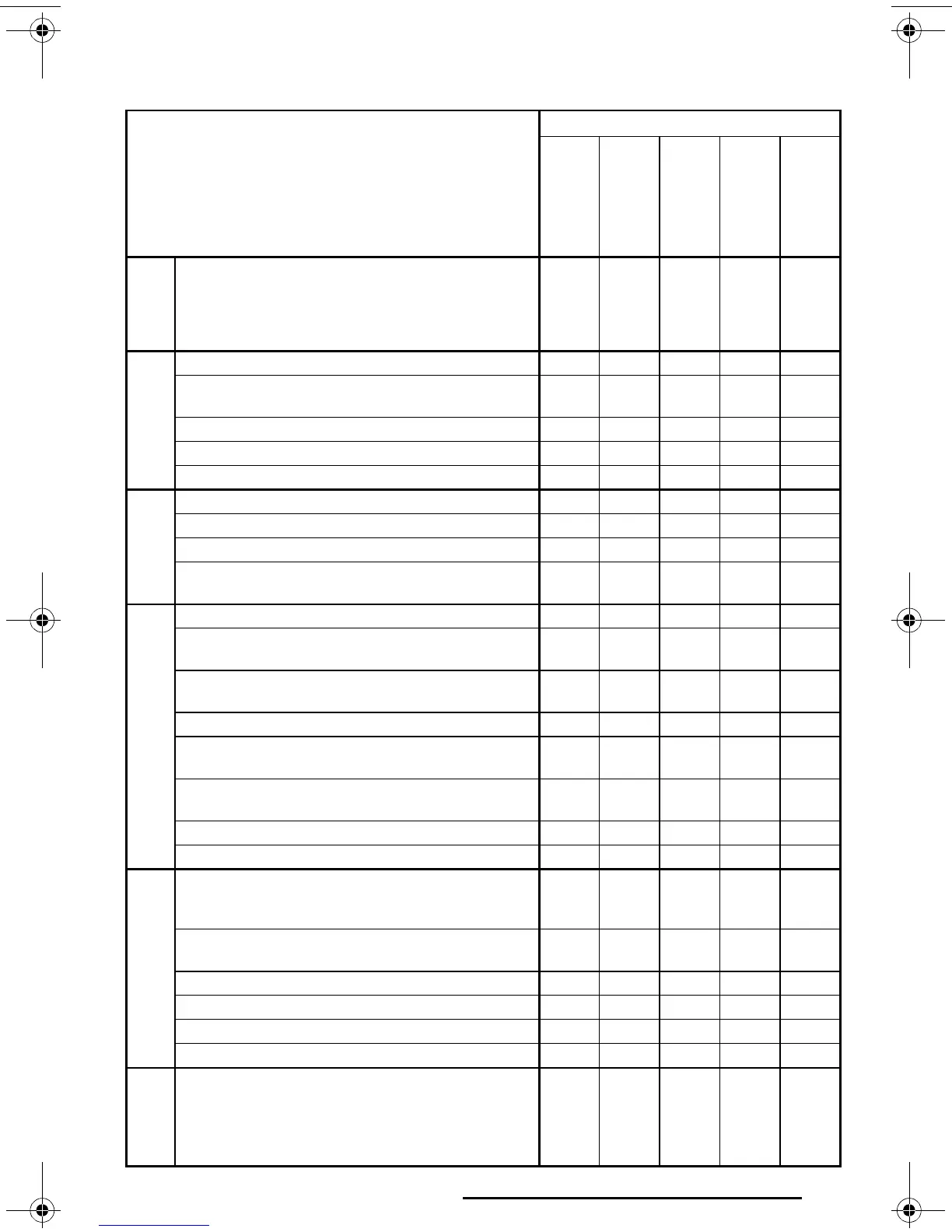

67

Periodic Inspection Chart

DESCRIPTION

FREQUENCY

FIRST 10

HOURS

EVERY 25

HOURS OR

3 MONTHS

EVERY 50

HOURS OR

6 MONTHS

EVERY 100

HOURS

OR 1 YEAR

TO BE

PERFORMED

BY

GENERAL

Lubrication/corrosion protection ✔ O

ENGINE

Engine oil and filter replacement ✔✔D

Support and rubber mount condition/

tightness

✔✔D

Condition of seals and fasteners ✔✔D

Exhaust system fasteners ➄✔ ✔D

Spark plug replacement ➄✔D

COOLING

SYSTEM

Flushing (exhaust system) ✔➂ O

Hose condition and fasteners ✔✔D

Coolant replacement ➃ D

Coolant expansion tank cap/cooling system

pressure test

➃ D

FUEL

SYSTEM

Throttle cable, inspection/lubrication ✔ O

Fuel injection system sensors, visual

inspection ➄

✔✔D

Throttle body cleaning and inspection. Fault

code reading ➄➀

✔ D

Fuel vent line pressure relief valve inspection ✔ D

Fuel lines, connections and fuel system

pressurization ➄

✔✔D

Visual inspection: throttle body, sensors, fuel

lines, fuel rail and fittings ➄

✔✔D

Air intake silencer fit/tightness ✔✔D

Fuel tank straps visual inspection ✔✔O

ELECTRICAL

SYSTEM

Electrical connections condition and

fastening (ignition system, starting system,

fuel injectors etc.)

✔✔D

MEM and engine ECU connectors inspection

and lubrication

✔➀ D

MPEM mounting brackets/fasteners ✔ D

Digitally Encoded Security System ✔✔D

Monitoring beeper ✔✔D

Battery condition and fasteners ✔✔D

STEERING

SYSTEM

Inspection and cable adjustment ✔✔D

smo2002-003b.fm Page 67 Thursday, December 6, 2001 2:16 PM

Loading...

Loading...