Rated on-load voltage U

o

in V

a) Peak value in case of direct current;

b) Peak & r

.m.s. value in case of alternating current.

Direct current

Fuse

X Duty cycle (Factor)

1

2

Rated weld current

U

2

Conventional load voltage

Mains supply and number of phases

(i.e. 1 or 3) with symbol for

alternating current.

(1)3

5. VARIOUS WELDING METHODS

4. MIG/MAG WELDING

Principles

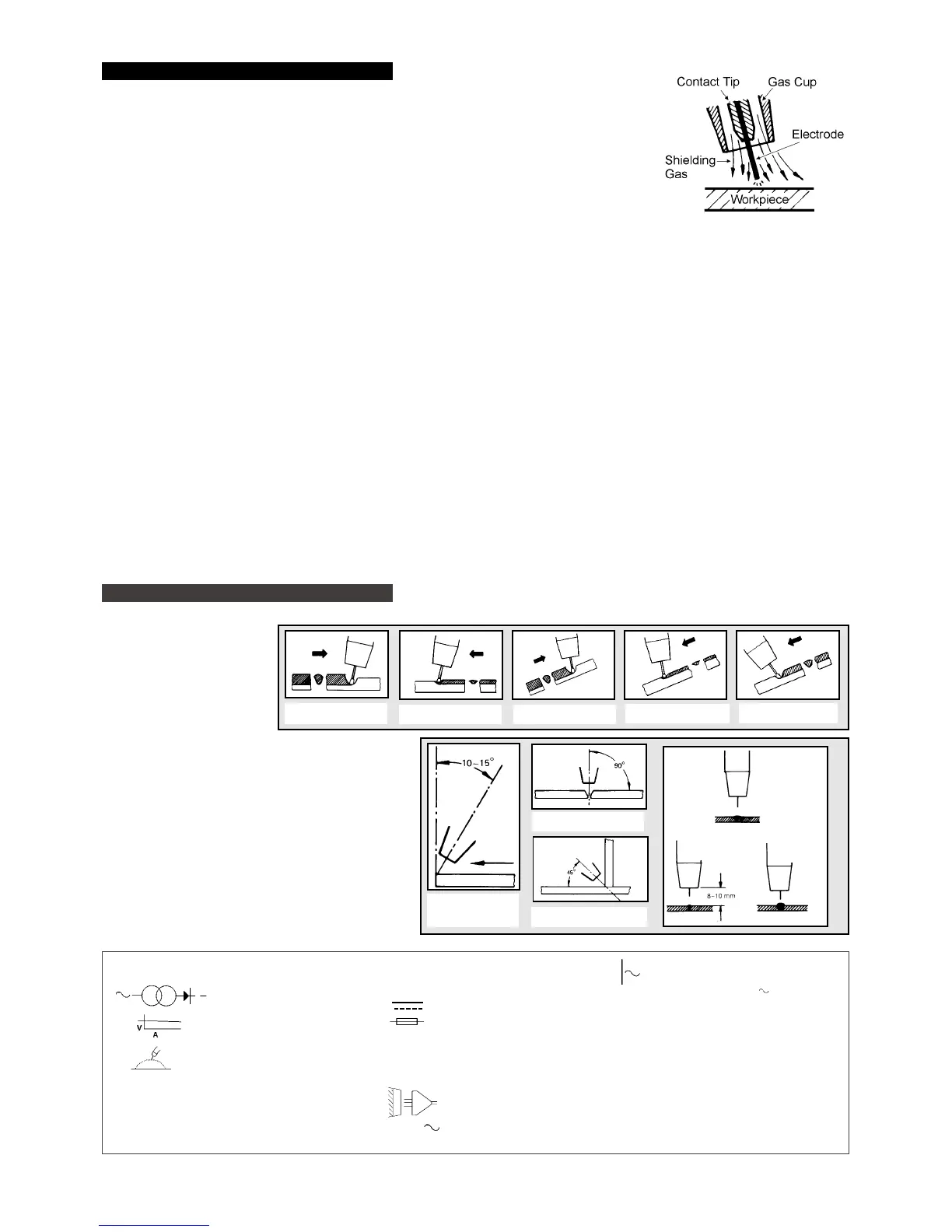

A spool of welding wire is positioned on the welders spool holder and automatically fed through

an insulated liner in the torch to the tip. The torch assembly consist of a switch, liner, gas hose,

and control cable. The switch activates the wire feed roller and the gas flow. Conversely, releasing

the switch stops the wire feed and gas flow. The weld current is transferred to the electrode (the wire)

from the contact tip at the end of the torch. A gas cup fits over the contact tip to direct the gas flow

towards the weld ensuring that the arc welding process is shielded from oxidising air contaminates.

The shielding gas also assists heating of the weld materials. The torch is connected to the positive

side of a DC rectifier, and the negative clamp is attached to the workpiece.

Preparation for welding.

IMPORT

ANT: Welder must be switched off at the mains before starting. If welding a vehicle, disconnect battery or fit an electronic circuit protector.

4.1. Connecting the Earth Lead

To ensure a complete circuit, the earth lead must be securely attached to the work piece that is to be welded.

4.1.1. The best connection is obtained by grinding clean the point of contact on the workpiece before connecting the earth clamp

to the job to be welded.

4.1.2. The weld area must also be free of paint, rust, grease, etc.

4.1.3. When welding a vehicle, be sure the vehicle battery is disconnected or fit a PROSAF/12V or 24V Electronic Circuit Protector

available from your Sealey dealer.

4.2. Setting Up

The Supermig250/10 has an automatic wire speed system, which for most effective welding should be set up as follows:

4.2.1. Select the voltage step that best suits the thickness of the material to be welded

4.2.2. Adjust the wire feed knob until a perfect weld bead is obtained.

NOTE: If the wire speed increases, even to reaching maximum, do not be concerned as the wire speed setting will re-adjust

correctly to any voltage step selected thereafter.

4.3. Welding mild steel

To weld mild steel you can use CO2 gas for most tasks where spatter and the high build up of weld do not pose a problem.

To achieve a spatter free and flat weld, you must use an Argon/CO2 mixture.

4.4. Welding aluminium

To weld aluminium use: 3 Argon gas, 3 0.8mm Contact Tip (AK957), 30.8mm Aluminium Wire, (MIG/2/KAL08).

Alternating current & the rated

frequency in hertz i.e. 50Hz

P

max

... kW

Maximum power consumption in case

of a rotating welding power source. This

value will only be given when it is not

combined with a prime mover.

U

1

... V/...Hz

Rated values of the supply voltage

and the frequency

.

/

1

Rated supply current.

IP Degree of protection, i.e. 21 or 23.

ED%

Duty cycle

%

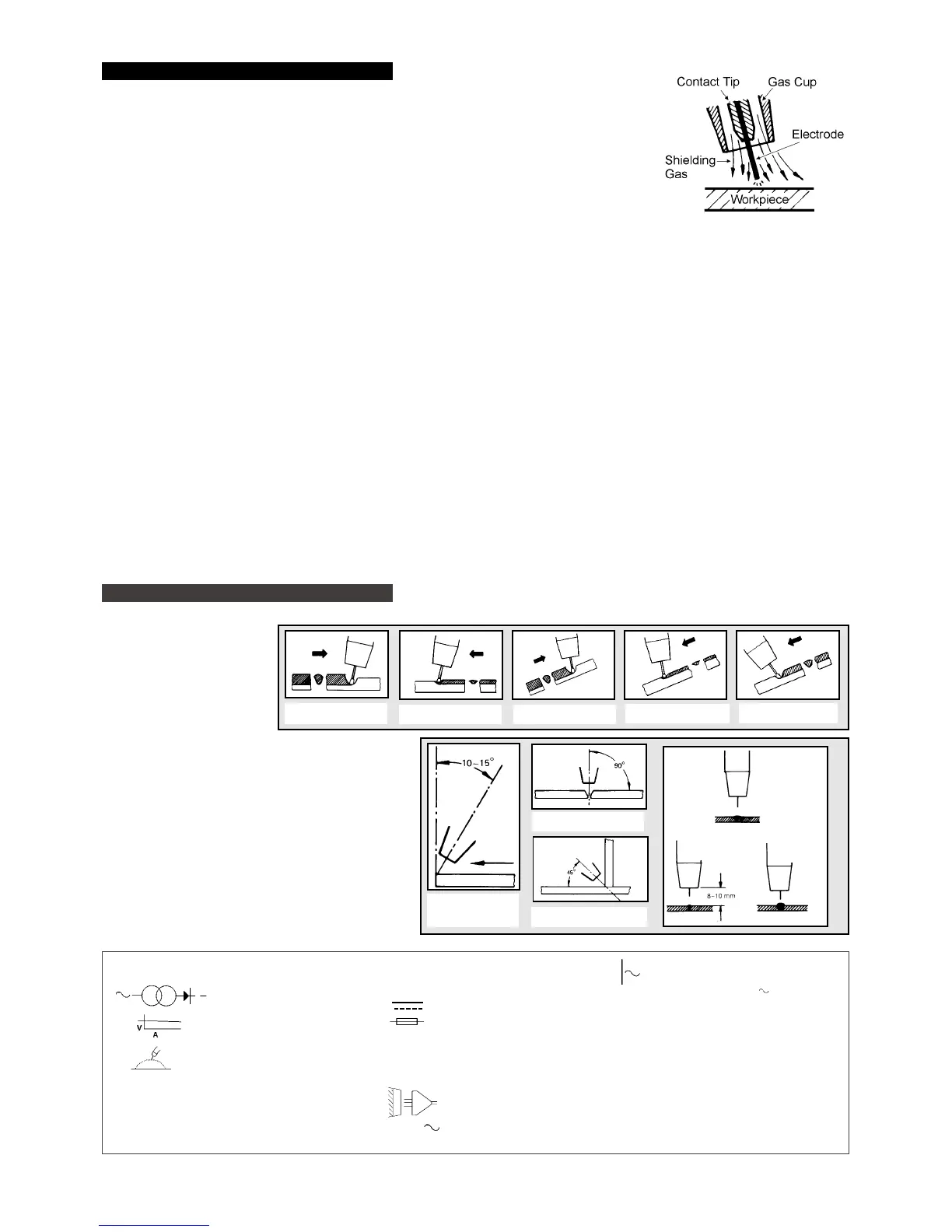

The position of the torch,

its angle and direction of travel

in relation to the workpiece

is essential for the appearance

and quality of the weld.

The illustrations demonstrate

various positions and directions.

Rightward Welding

Welding in general

W

elding with a long arc reduces penetration and widens

the arc.

This in turn results in more spatter

.

A long welding arc can be appropriate for welding butt

joints in thin materials.

Welding with a short arc (at the same weld settings)

results in greater penetration and a narrower weld

and reduces the amount of spatter.

Leftward Welding

Vertical Rightward

Downhard leftward

Down Rightward

1. Direction of

Welding

3. Fillet Weld

3. Butt Weld

Normal

Welding

Arc

Long

Welding

Arc

Short

W

elding

Arc

MEANINGS OF MARKINGS, AND SYMBOLS

Single Phase transformer & rectifier

Flat Characteristic

MIG/MAG welding

...A/ ... V to ...A/ ... V Range of output, rated min

& max welding current and

their corresponding conventional

load voltage.

PA kVA Power Efficiency

SUPERMIG 250-Job181-280198

Loading...

Loading...