SEL-2414 Data Sheet Schweitzer Engineering Laboratories, Inc.

2

➤

Advanced Asset Monitoring. Monitor critical substation assets with comprehensive transformer thermal and

through-fault monitoring. Calculate top oil, hot-spot, insulation aging acceleration factor, and loss of life while

generating hourly and daily data about your transformer. Capture the maximum/minimum values of all trans-

former model quantities. Capture through-fault current data that could lead to increased transformer wear.

➤ Critical Reporting and Logging. Store as many as 512 Sequential Events Recorder (SER) reports of digital input

transitions, time-tagged to the nearest millisecond. Analyze SER reports, analog trending, and oscillographic event

reports for rapid commissioning, testing, and post-event diagnostics. Send the SER data to a communications pro-

cessor or computer for system analysis.

➤ Communications and Integration. Automate fan bank control with flexible communications options that provide

easy integration with SCADA. Choose from single and dual Ethernet, Modbus

®

TCP, DNP3 LAN/WAN,

IEC 61850 Ed. 2, Modbus Serial, EIA-232, EIA-485, Telnet, and File Transfer protocols.

➤ AC Metering Capabilities. Take advantage of extensive ac metering and monitoring capabilities. Voltage, current,

power, energy, power factor, frequency; demand/peak demand metering; and maximum/minimum metering are

measured and recorded. Values can be used in programmable calculations and triggers within the meter.

➤ Simple Commissioning Tools. Make use of a front-panel HMI that provides complete configuration access and

displays settings, measurements, and calculated values. Easily set with

ACSELERATOR QuickSet

®

SEL-5030 Soft-

ware.

Product Summary

The SEL-2414 Transformer Monitor withstands harsh physical and electrical environments and is built and tested to

meet mission-critical IEEE and IEC protective relay standards. Apply the SEL-2414 to satisfy standalone or distributed

monitoring and control of transformers, or choose from the flexible communications options to connect to a substation

distributed SCADA or automation system, or a SCADA master. Communications options include serial, fiber-optic, and

Ethernet connections and ASCII, SEL Fast Message, M

IRRORED BITS

®

communications, Modbus, and DNP3 protocols.

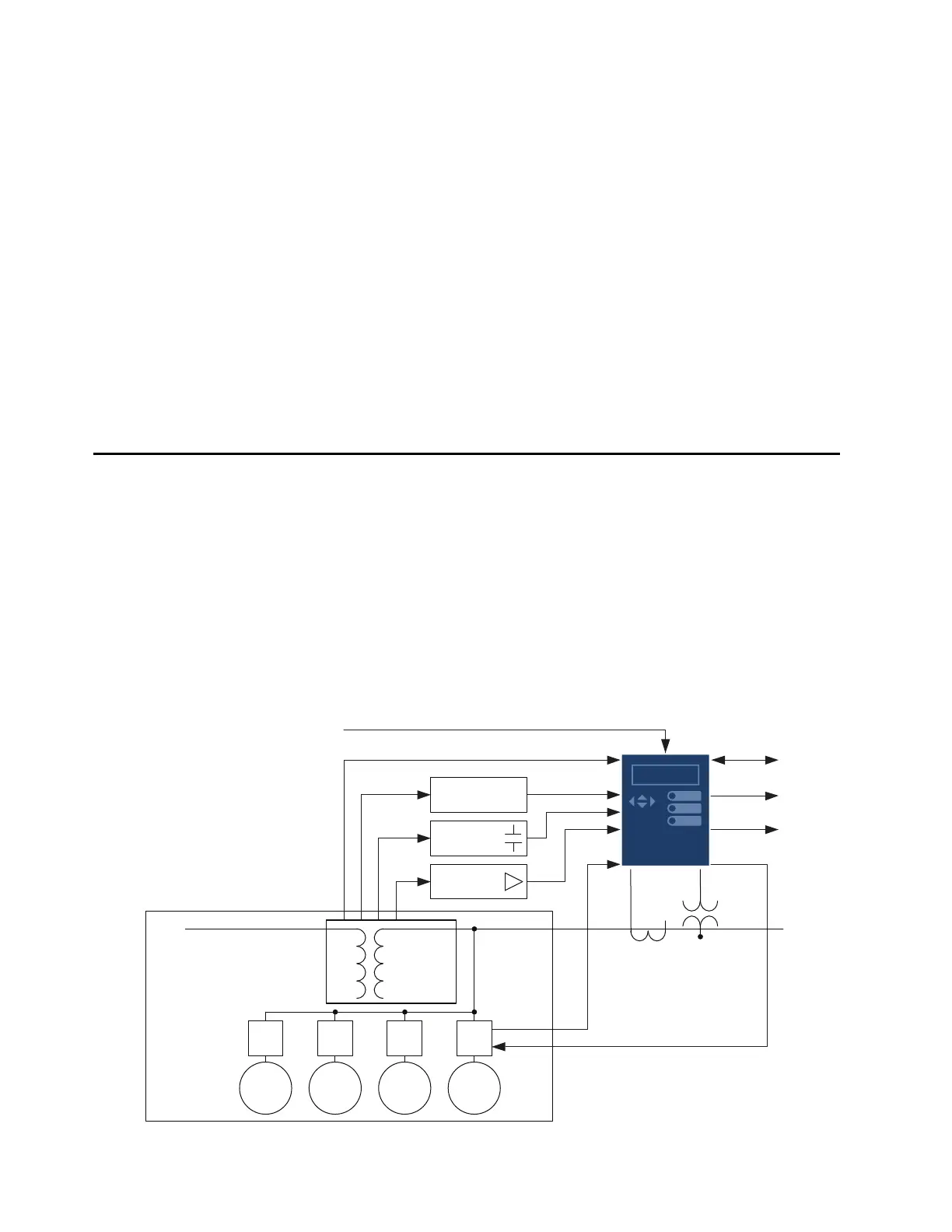

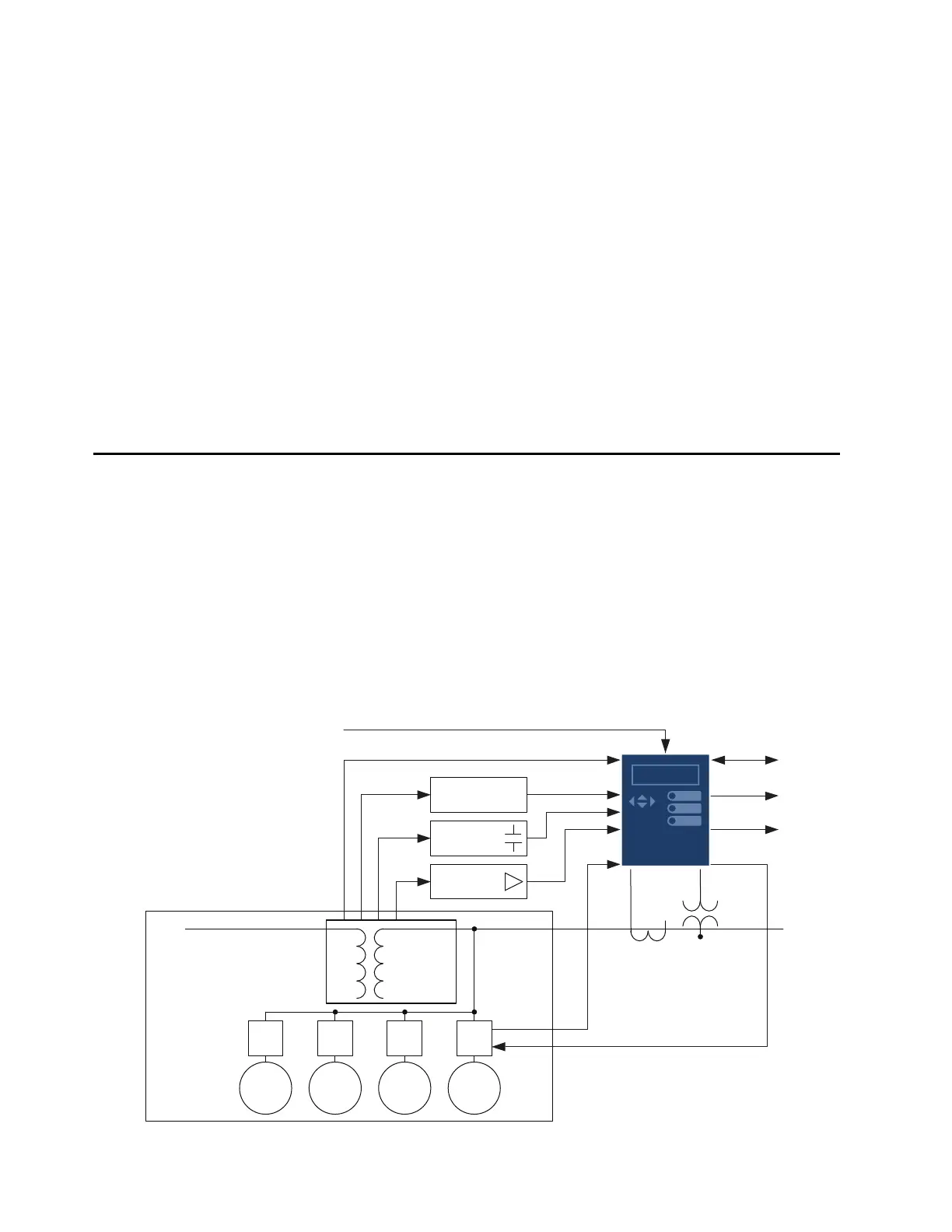

Figure 1 shows the SEL-2414 functionality.

Apply flexible I/O options to meet the many needs of new or retrofit transformer installations. The SEL-2414 includes

four slots for plug-in I/O cards. Use digital inputs (DI) to monitor critical transformer alarms and status points. Use

analog inputs (AI) to measure pressure, oil level, temperatures, tap positions, and process-level signals (e.g., 4–20 mA,

0–1 mA) from transducers. Operate cooling fans, equipment, alarms, or provide indication with relay-contact or solid-

state digital outputs (DO) and analog outputs (AO). Measure ac currents and ac voltage to calculate three-phase power,

demand, energy, save in oscillographic reports, and for automatic control processes.

Figure 1 Transformer Monitor and Control System

SEL-2600 RTD

Transducer

IRIG-B

Up to 10 RTDs or TC (°C)

Up to 12 RTDs

Communications

Alarms

DNP3

Alarms (DOs)

Analog Outputs

Currents Voltages

Status

52 = Breaker

M = Cooling Fan Motor

Control

Sensor(s)

with DOs

Sensor(s)

with AOs (mA)

Core & Coil

Transformer

52

M

52

M

52

M

52

M

SEL -24 14

Loading...

Loading...