Cables for forward- facing electrical installations are

held in place with an ”ETHAFOAM” pad to eliminate

slapping.

If additional cables from mid mast installations are

required, proceed as follows.

Lay the mast with forward face uppermost so that

the cables will rest in one comer of the conduit.

Drill the exit hole for the cable through the other

corner and forward of the cable. Use great caution

when drilling so as not to damage the cable.

Carefully burr the hole to eliminate any sharp

edges that could cause chafe. Some tape around

the cable will give added protection.

1.

2.

3.

Running cables

All in-mast furling mast extrusions have one or more cable conduits. These run uninterrupted to the mast heel

even on keel stepped masts.

A messenger is threaded through all empty conduits at the factory to facilitate cable drawing.

A new messenger should be drawn through a conduit at the same time as a cable is drawn through. This will

facilitate the running of additional cables.

If an existing cable should prevent a new one being run, it should be extracted after first having attached a new

messenger to it to take its place in the conduit. That messenger can then be used to pull two or more cables

through the conduit simultaneously.

Cables are led into a conduit at the masthead through a hole in the side of the mast extrusion. Cables should be

over-length. The head box can then later be removed without the need to disconnect electric installations. Cable

exits are located in the mast heel casting.

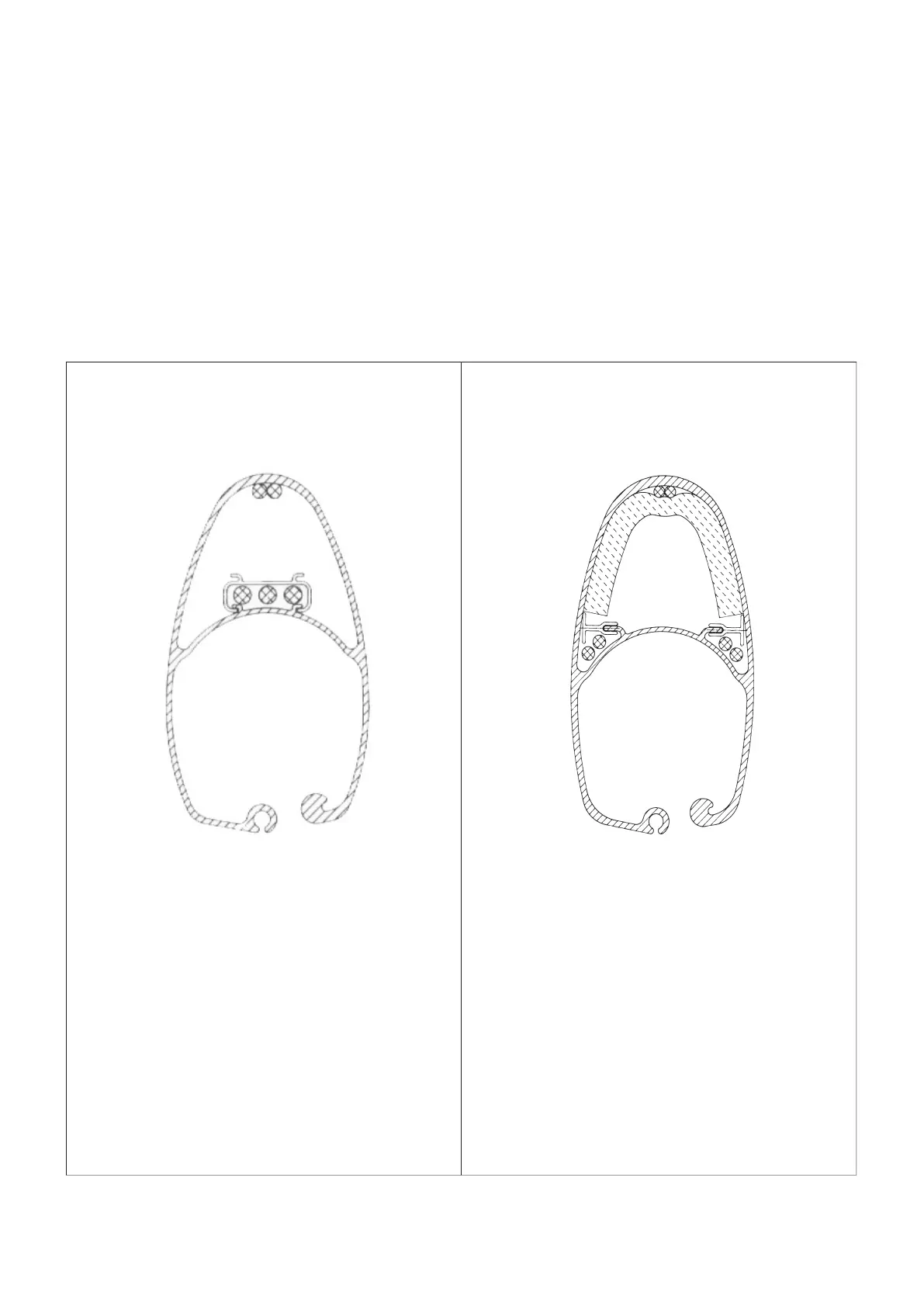

Extrusion:

232/126

260/136

290/150

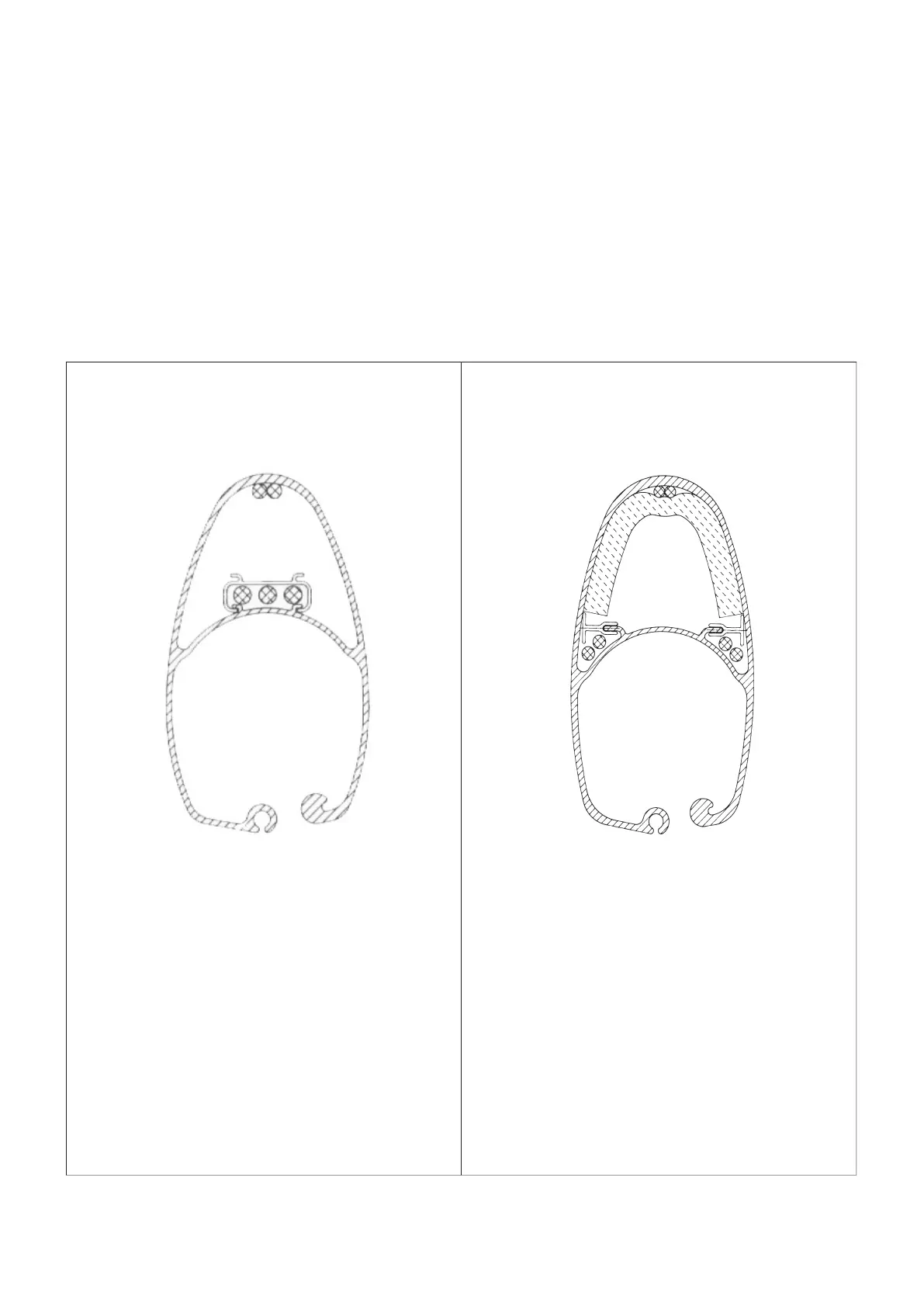

Fig. 11.1 Fig. 11.2

Extrusion:

214/122

Loading...

Loading...