Removal of the in-mast furling mast gear from the mast

Lay the mast horizontally on trestles.

Detach the luff extrusion from the in-mast furling mast gear by slackening the tension and undoing the togg-

le. (See page 4, ”Luff extrusion adjustment”).

Remove the in-mast furling mast gear from the mast by undoing the eight holding bolts and taking it away

from the mast. (The in-mast furling mast gear can be removed even when the mast is stepped).

Remove the headbox by undoing the nuts on top and lifting it off.

Remove the top swivel from the luff extrusion.

Top swivel 540-104: Undo the two lower bolts. (The upper bolts holds the swivel halves together).

Top swivel 540-204: Undo the three lower bolts. (The upper bolts holds the swivel halves together).

Slide the halyard swivel off the luff extrusion.

1.

2.

3.

4.

5.

6.

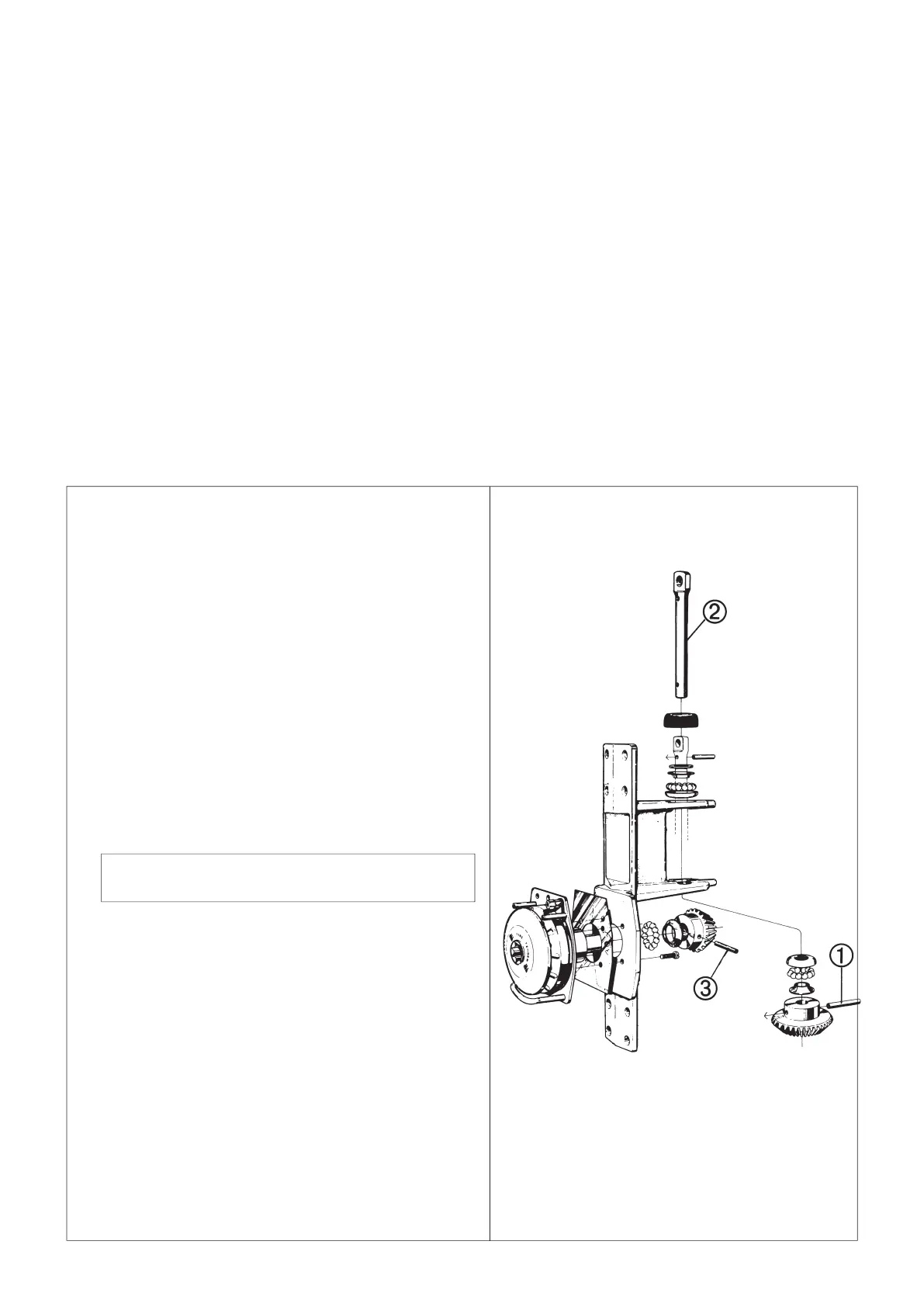

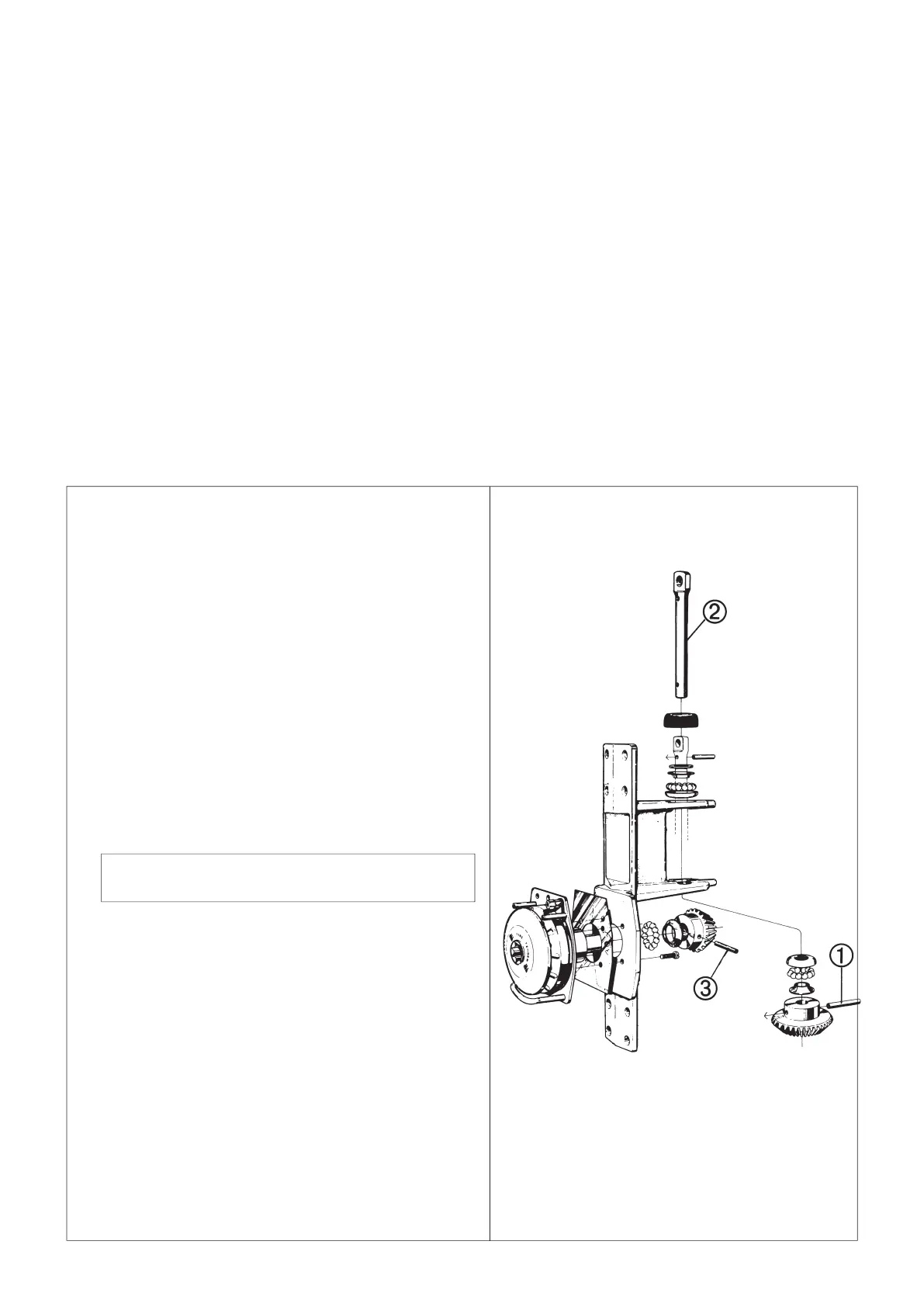

Dismantling units with ball bearings

All dismantling should be undertaken on a clean unbroken surface. The various ball bearing units contain

many small parts that fall apart when dismantling. Lay the dismantled parts out in an orderly manner.

Dismantling the in-mast furling mast gear

Tools required:

– Hammer

– Punch, (6 –8 mm) (1/4–5/16”).

– Allen key, 6 mm.

– Screwdriver, small

Drive the spring-pin

from the large bevel gear.

Use hammer and punch.

Draw the shaft

up and out from the in-mast

furling mast gear.Take care of the balls and races

which will fall apart.

Drive out the spring-pin

from the small bevel

gear. Draw the gear and ball bearings off the shaft.

Take care of ball bearings and races, which will fall

apart.

Undo the four bolts holding the reefing winch, and

remove the winch from the holding bracket.

Remove loose components from the reverse side

of the winch, and remove the locking ring from the

shaft. The winch can then be dismantled.

Clean the ball bearings, their races, gears, and

winch components in a white spirit bath.

Reassemble all components in the reverse order.

The winch must be greased before reassembly. A

layer of grease in the cupped half of a ball-race will

hold the balls in place during assembly. Grease the

bevel gear teeth.

1.

2.

3.

4.

5.

6.

Fig 14.1

Loading...

Loading...