Anti-vibration strip

Vibration can occur in any aluminium mast of normal design. With wind coming from approximately abeam at

speeds of 4–12 Knots the mast oscillates longitudinally at a rate of 3–6 cycles per second. Every Seldén Mast

in-mast furling mast is supplied with an ”anti-vibration strip” for hoisting in the integral sail groove to prevent

vibration starting. It will also reduce wind noise.

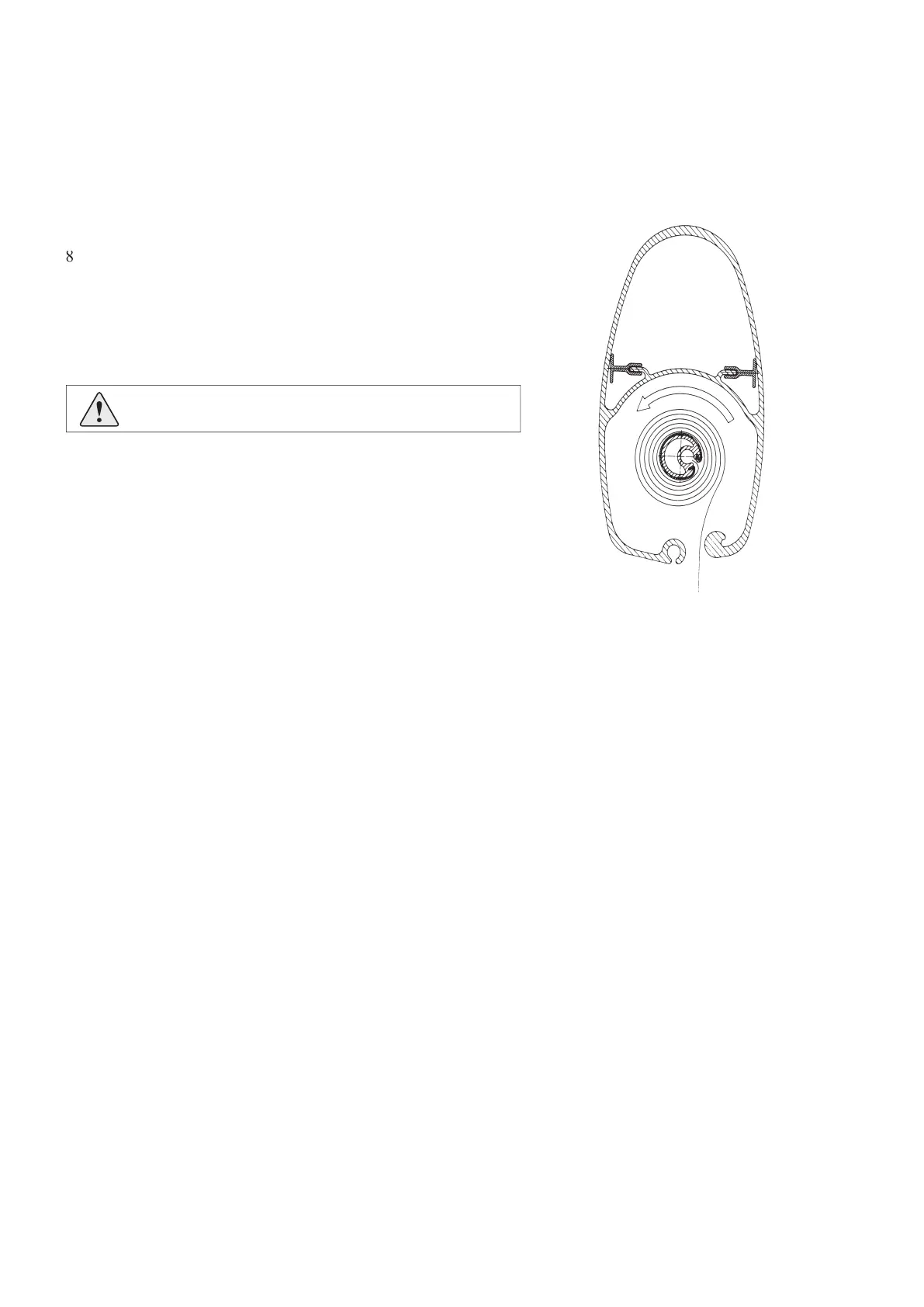

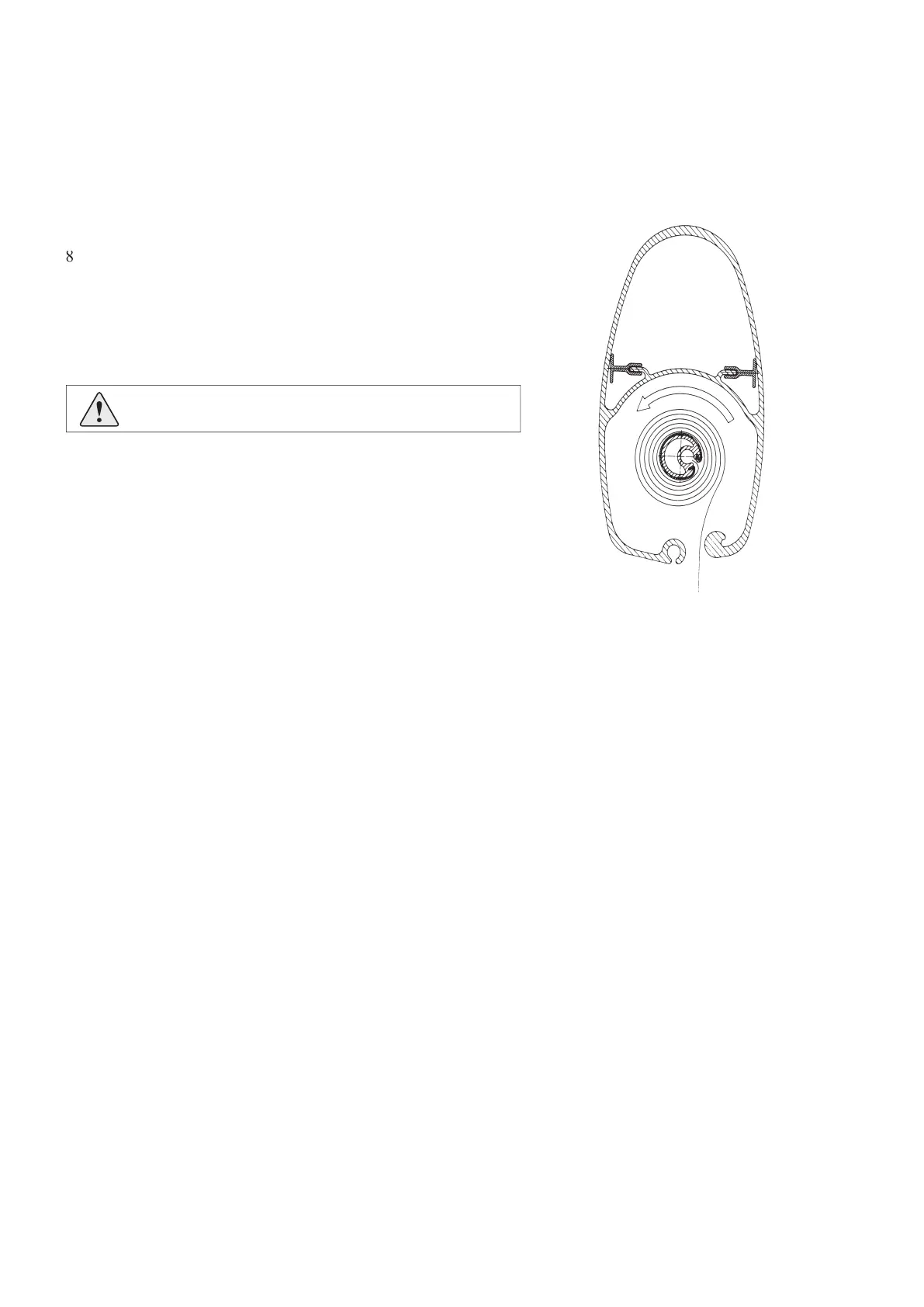

Port

Fig. 9.1

Starboard

Before sailing

1. Check that the sail is correctly furled on the luff extrusion: i.e. to its starboard side. (See fig. 9.1).

2. Whilst still on the mooring furl and unfurl the sail a couple of times to ensure that the system works as it

should, and to familiarise yourself with its operation, and also to check that the sail is correct size.

3. Adjust the topping lift to achieve the desired sail shape. The topping lift determines sail twist; its effect

being comparable to chan

ging foresail sheeting angles.

Note. Turn the reefing winch clockwise for correct

furling.

. Hoist the mainsail whilst simultaneously ensuring that it is feeding correctly into the luff extrusion.

6. Set the halyard and cleat it with the rope stopper. The halyard tail can be stowed in the mast by

feeding it through the hole just below the halyard winch.

. Furl the sail until the clew is exposed. The luff extrusion is asymmetrical to facilitate rolling in one direc-

tion, and the sail should always be rolled onto the starboard side of the luff extrusion. The reefi ng winch

should be turned clockwise. See fi g. 9.1.

. Attach the clew to the outhaul car.

The integral luff-groove on the after face of the mast can med used for hoisting a spare sail. A foresail made to fi t

the Furlex luff foul can be used. The luff groove dimensions are the same as those for the roller extrusion, as shown

If the spare sail is fi tted with slides, then Aquabatten No. A032 or Rutgerson 101 are recommended.

Loading...

Loading...