Installation and Service Manual

25

OPERATION

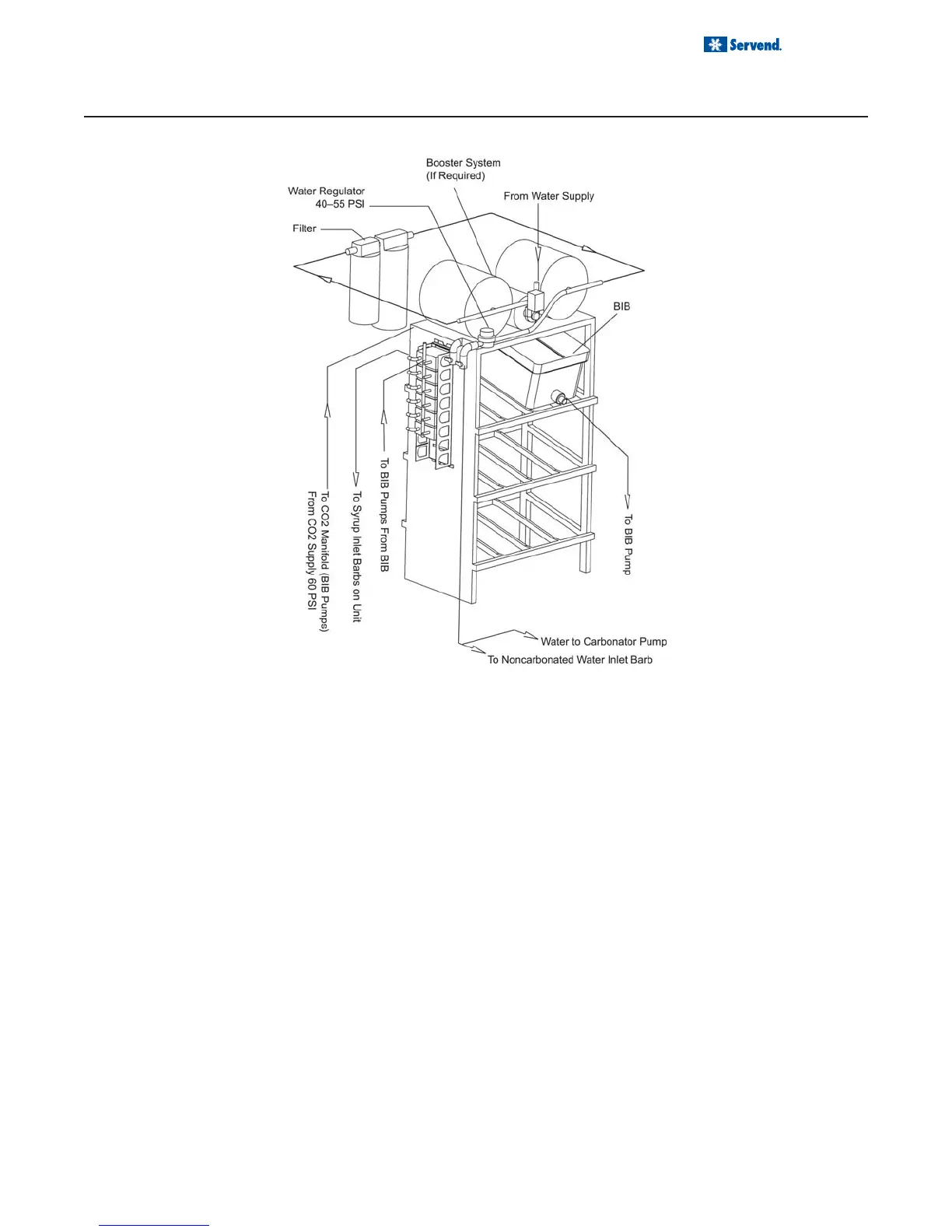

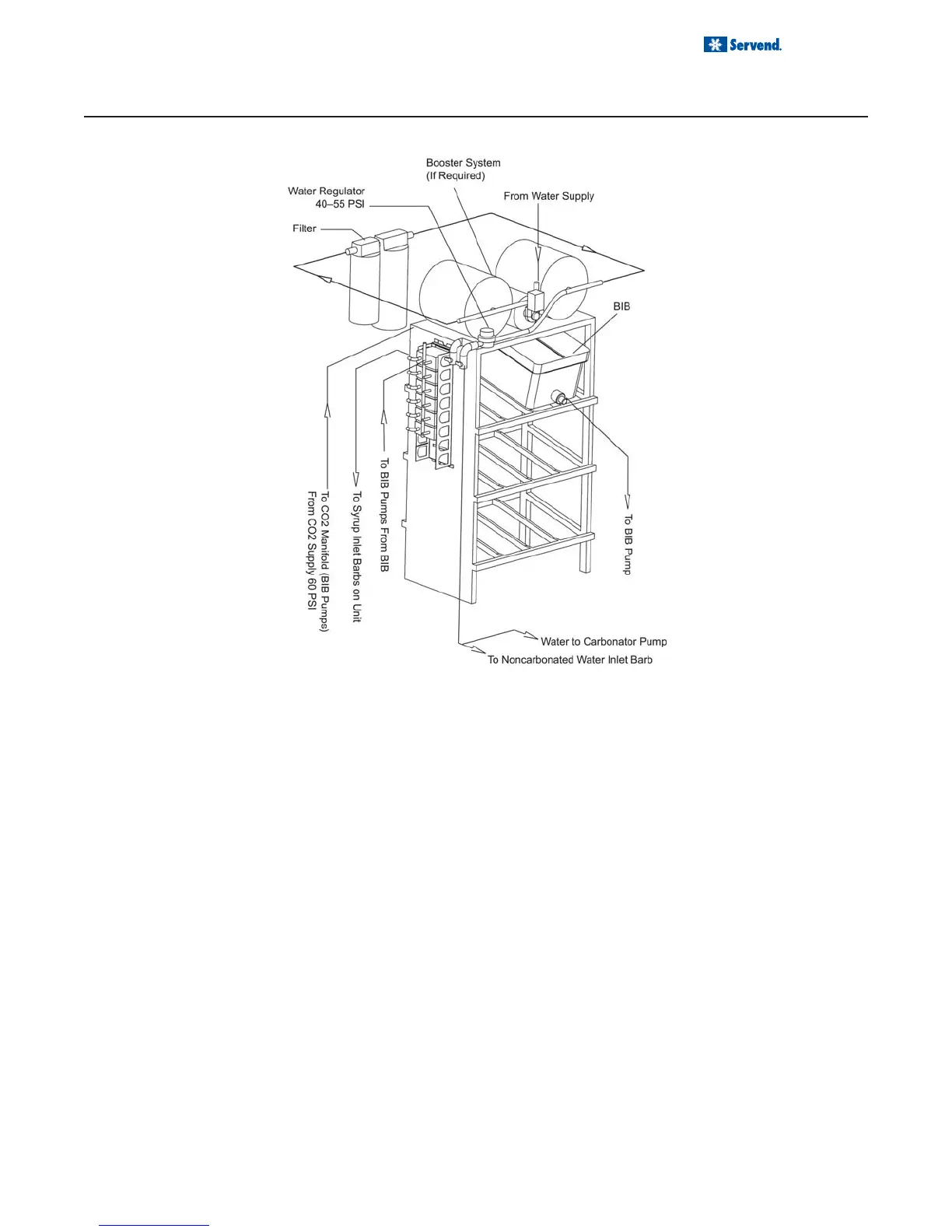

BACK ROOM PACKAGE

BAG-IN-BOX SYSTEM

Creating Carbonated Water:

1. Incoming tap water - should be at a minimum dy-

namic pressure of 40 psi and maximum static pres-

sure of 55 psi.

2. Carbonator Water pump motor - Powers the wa-

ter pump. The water pump motor is part of the car-

bonator pump deck.

3. Carbonator Water pump - Pumps tap water into

the carbonator tank. The water pump is part of the

carbonator. The incoming water for the carbonator

must be first ran through the pump before connect-

ing to the proper cold plate inlet.

4. Internal/External Carbonator tank - Combines

CO

2

gas and tap water to form carbonated water.

The “carbonator” is the carbonator tank, water pump

and water pump motor.

On an ambient system, after being carbonated, the car-

bonated water is fed from the carbonator to the dispenser

cold plate for chilling. At the beverage valve, chilled water

and chilled syrup are mixed to create the finished bever-

age. A cold carbonated system pre-chills the water be-

fore entering the carbonator tank.

Pumping Syrup to the Dispenser:

5. CO

2

cylinder - Holds highly pressurized carbon di-

oxide (CO

2

). The CO

2

cylinder is a steel or alumi-

num cylinder tank. CO

2

gas flows to the primary

pressure regulator.

6. Cylinder pressure gauge - Indicates amount of

CO

2

gas in the cylinder.

7. Primary pressure regulator - Lowers the CO

2

gas

pressure, to 100 psi, so the CO

2

gas will be at the

proper pressure to enter the carbonator regulator.

8. Lowered outgoing pressure - Set for 75 psi.

Gauge indicated lowered outgoing pressure from

the CO

2

cylinder after being routed through the pri-

mary pressure regulator at 100 psi..

9. Secondary pressure regulator - Lowers the CO

2

gas pressure before the CO

2

gas flows to the syrup

pump. CO

2

pressure, 60 to 75 PSI, activates the

syrup pump.

10. Syrup pump - Draws syrup out of the bag-in-box

syrup package. Syrup flows through the syrup lines

to the dispenser for chilling, then dispensing. There

is a syrup pump for each bag-in-box syrup system.

11. Bag-In-Box syrup cartons - Box which contains a

plastic bag, filled with syrup.

Loading...

Loading...