WOOD BOILER INSTRUCTIONS Page 58 Copyright © 2011 Seton Wood Boilers all rights reserved

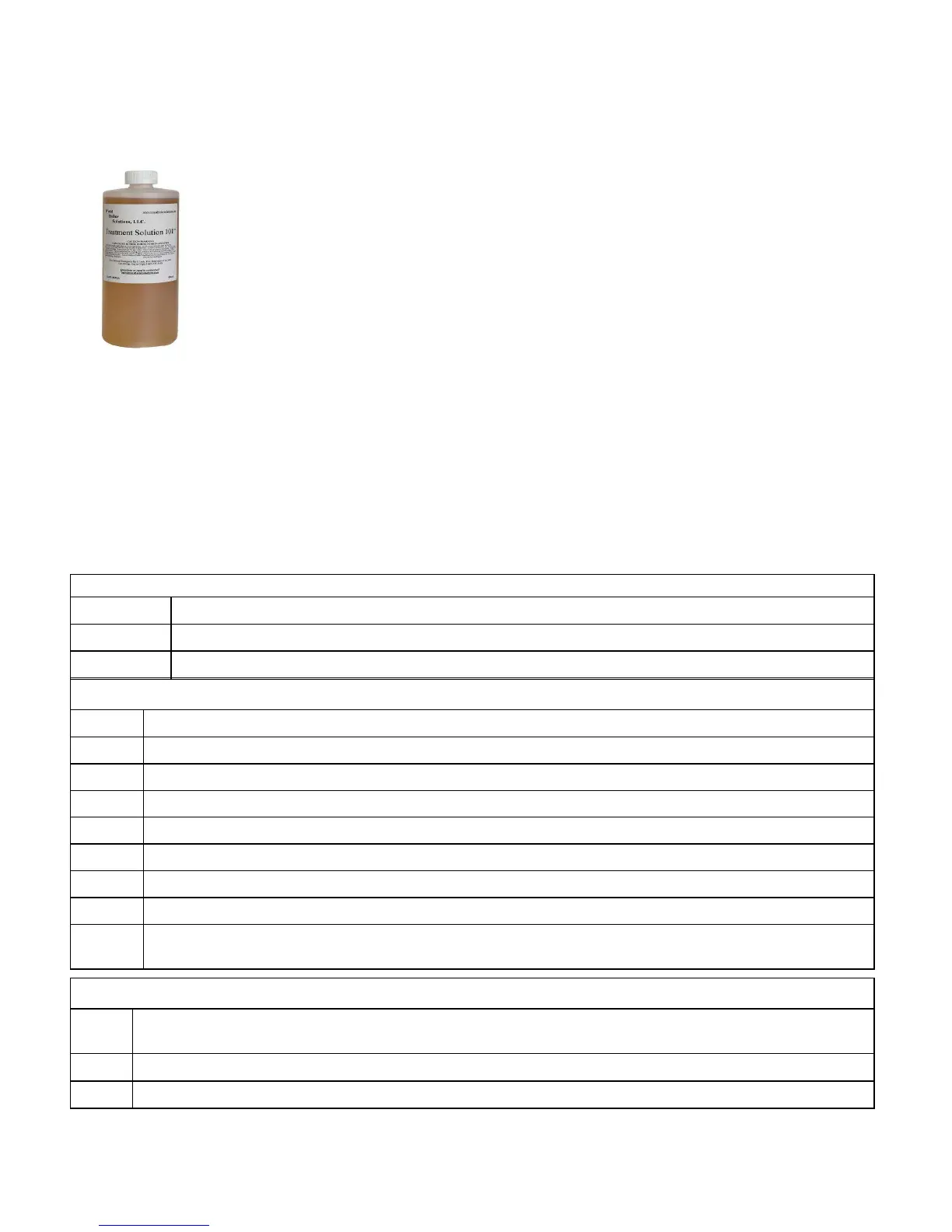

Step 1 Flush system with clean water. Add Prep Solution 102™ per directions.

Step 2 Drain and flush thoroughly.

Step 3 Refill and add required amount of Treatment Solution 101™ per directions. System is ready to use.

Step 4 Test chemical level biannually, adding as necessary to always maintain a proper chemical level.

Step 5 Add Biological Solution per instructions every third season or as necessary to control biological growth.

The Successful Plan - Pressurized "Closed" Outdoor Wood Boiler

BOILER MAINTENANCE

Step 1 Clean and passivate system with required amount of Prep Solution 102™ per directions for new boiler.

Step 2 Drain and flush thoroughly.

Step 3 Refill and add required amount of Treatment Solution 101™. System is ready for use.

Step 4 Test chemical level each month and add accordingly to always maintain a proper chemical level.

Step 5 Prior to the end of the heating season and draining add Lay -Up Solution 103™ per directions.

Step 6 Drain and flush thoroughly.

Step 7 Refill and add required amount of Treatment Solution 101™. Add required amount of Biological Solution

Step 8 Repeat Steps 4 - 7.

**

If necessary use Scale-Out Solution 115™ per directions at Step 5 in place of Lay-Up Solution 103™. (FLUSH

THOROUGHLY) Following Scale-Out repeat steps beginning with Step 1.

New Non-Pressurized "Open" Outdoor Wood Boiler

Step 1

Address and remove existing scale deposits if any exist following directions and dosages for Scale-Out Solution .

(FLUSH THOROUGHLY)

Step 2 Clean and passivate system with required amount of Prep Solution 102™ per directions for an existing boiler.

Step 3 Follow Steps 2-8 for a new outdoor wood boiler.

Existing Non-Pressurized "Open" Outdoor Wood Boiler

There is lots of “stuff” in your water, especially well water (municipalities treat water to

some varying degree in relation to our purposes, therefore problems are lessened with

"city" water supplies), all which pose problems for your system. Examples: calcium

(lime), iron, oxygen. That is why you treat the water. A "closed" system is no exception.

Without proper treatment of the water in your system you are allowing corrosion and

scale deposition to destroy the metals and destroy the efficiency and longevity of your

system. Scaling issues are decreased considerably but oxygen remains a threat to your

system. "Closed" systems are by no means air tight. Your outdoor wood boiler has basic

treatment requirements in regard to properly and effectively using water as a medium

for heat exchange as its larger industrial cousins. Same kinds of problems, same kind of

medicine. Regardless of the metals used to construct your particular brand boiler they

ALL need treatment EQUALLY.

Water treatment is an ongoing preventative maintenance process, NOT a one time

“dump a jug in and I’m done” process. You change the oil in your car periodically even

if the dipstick says full don’t you?! Water treatment maintenance is lessened for a

"closed" system compared to an "open".

Loading...

Loading...