21S-FX10L

5 – 7

SCREEN, WHITE BALANCE, SUB-BRIGHTNESS & SUB-CONTRAST ADJUSTMENT(2)

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE

WAVEFORM OR OTHERS

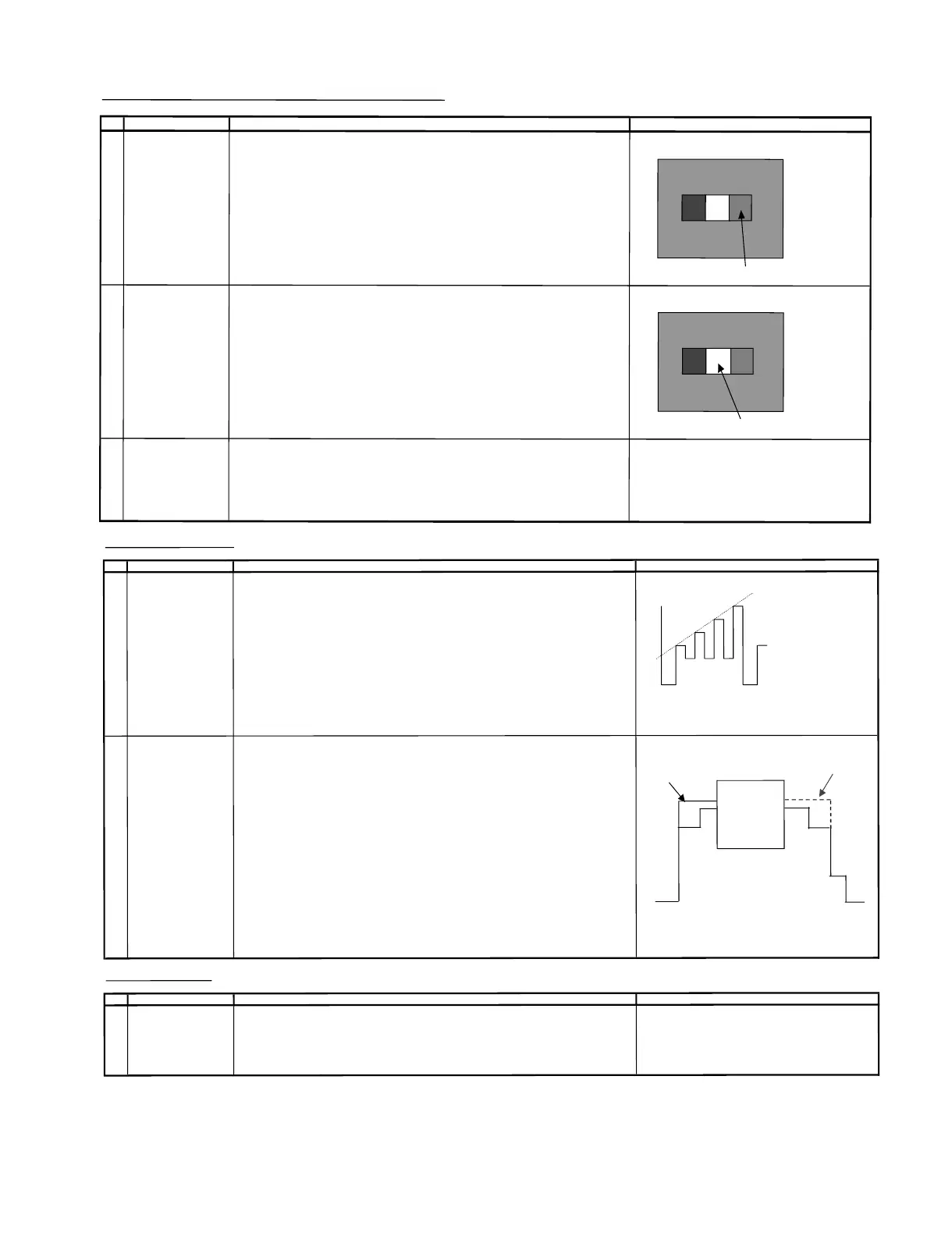

3 SUB-BRIGHTNESS (1) In CH 23 50IRE window pattern signal condition.

(to be done after screen, (2) Using Minolta Color Analyzer CA-100, let the gun point at

Dark White position

white balance adj) (as attach drawing), adjust V04 Bus data until

BRIGHTNESS Y

= 1.5cd/m2

(I2C BUS CONTROL)

4

SUB-CONTRAST (1) In CH 23 50IRE window pat

tern sign

al condition.

(to be done after screen,

(2) Using Minolta Color Analyzer CA-100, let the gun point at

W

hite

po

s

ition

white balance adj, (as attach drawing), adjust V01 Bus data until BRIGHTNESS Y

= 150cd/m2

sub-brightness adj)

(I2C BUS CONTROL)

** NOTE: Allowable Data for V01 >=90, even Y can't match the spec

White

5 BEAM CURRENT CHECK (1) Receive US 4 CH LION HEAD Signal (NTSC 60 Hz).

(2)

Press R/C to set Picture NORMAL condition.

(3) Connect the DC miliammeter between TP 603 ( +)&TP602(-)

(Full Scale: 3m

A Range).

(4) Beam current must be within :

1000 ± 100μA

US14

Dark White

US14

NTSC CHROMA ADJUSTMENT

NO ADJUSTMENT POIN

ADJUSTMENT CONDITION / PROCEDUR

WAVEFORM OR REMARK

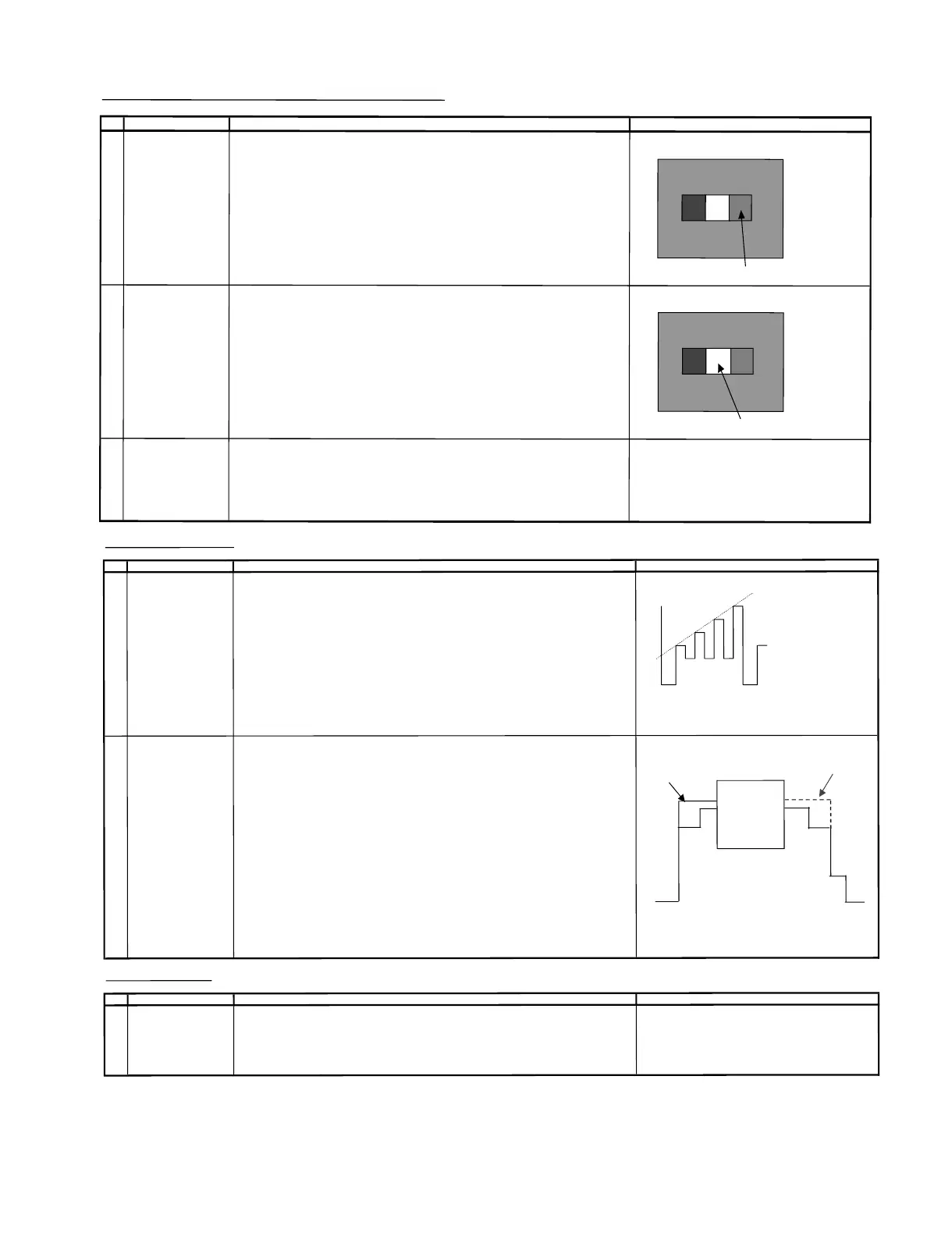

1 SUB-TINT

(1) Receive the "US 10 CH HALF Color Bar" signal.

(2) Connect the oscilloscope to JA410 or TP853 B

LUE-OUT

(I2C BUS CONTROL)

R

ange : 500mV/Div (AC) (Use Probe 10:1)

Sweep time : 10μsec/Div

(3) Select the servicedata V02 . On Y-mute using the R/C.

(4) Adjust the V02 (Sub tint) data to obtain the waveform as shown in Figure 1.

1

(B-Amp Bas

e (TP853) must be in stepping level)

*REMARK : PLEASE MAKE SUR

E

USE RF SIGNAL DURING SUB TINT ADJUSTMENT

Fig 1-1

2S

UB COLOR (1) R

eceive the "US 10 CH HALF Color

B

a

r" signal.

(2)

Make the image normal

with the remote controlle

r.

(I2C BUS CON

TROL) (3) Connec

t the oscilloscope to JA401 (TP851) RED-OUT.

(to be done after

sub tint adj) R

ange : 500mV/Div (AC) ( Use Probe 10:1)

Sweep time : 10μsec/Div

(4) Select the service data V03. Adjust the

V03 (Sub color) data to obt

ain the waveform

adjustment showninFig. 1-2.

(5) Fig 1.2 waveforms shows that the 75% white & red portions of color bar at the sa

me level

*REMARK

: PLEASE

MAKE SURE USE R

F SIGNAL DURING SUB COLO

UR ADJUSTMENT

Fig 1-2

M

S LEVEL ADJUSTMEN

T

NO ADJ

USTMENT PO

IN

ADJUSTMENT C

O

NDITION / PROCEDUR

WAVEFORM OR REMARK

1

MS LEVEL (1) R

e

ceive the "US 10 CH HALF Color Bar" signal.

ADJUS

TMENT

(2)

C

onnect the oscillosc

ope to IC3003

pin 17 ( C3014 -VE).

(I2C BUS CONTRO

L) (3) Se

t

the sound

volume c

ontrol

more than 1.

(4) Adjust the bus data

M01

unti

l

t

he voltage of IC3003 pin 17 (C3014 -VE) become as follows:

530m (+

18m,-35m) Vr

m

s

W

Y

Cy

G

100% WHITE

Mg

R

B

Loading...

Loading...