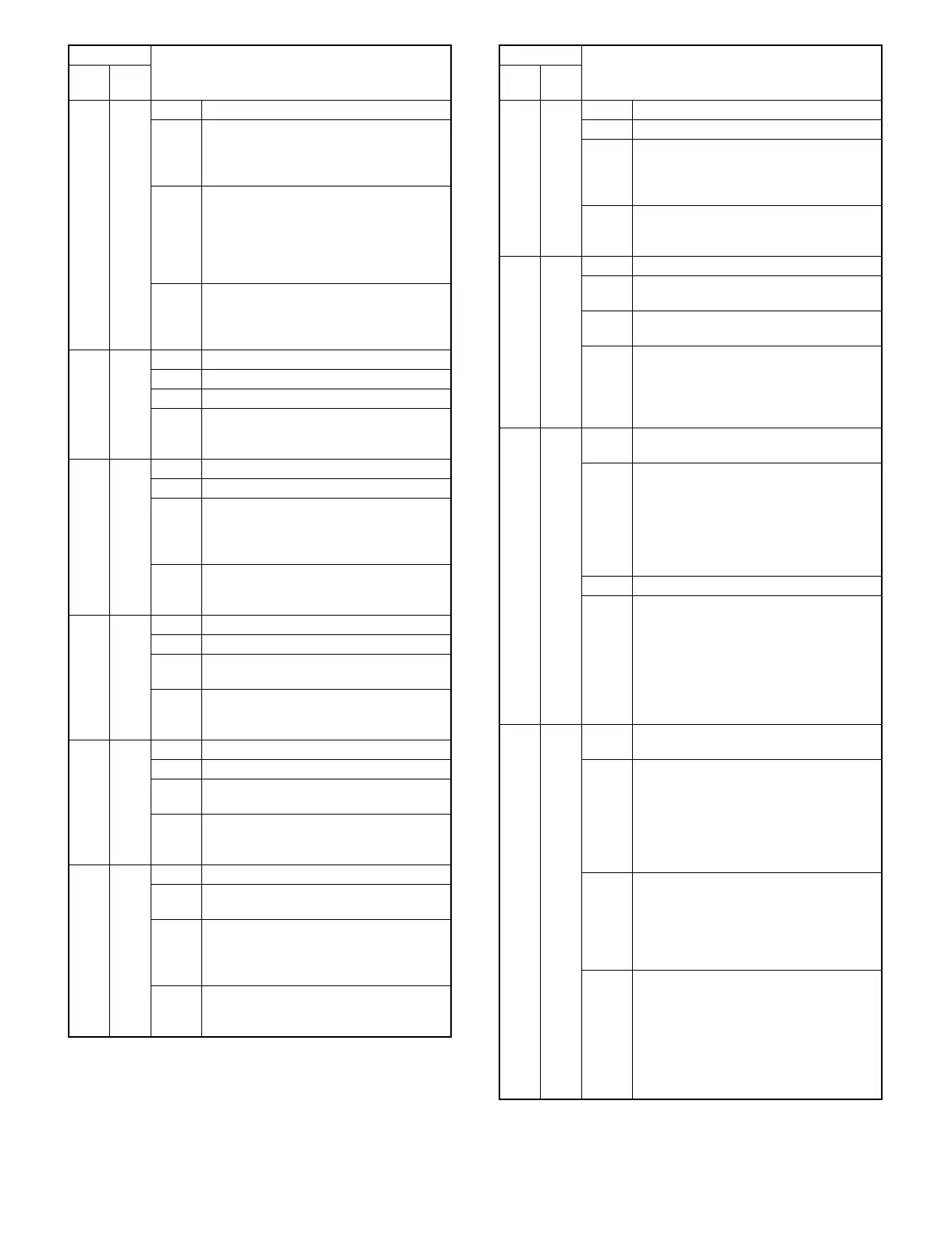

Trouble code

Description

Main

code

Sub

code

F1 00 Content Sorter communication trouble

Detail Communication line test error occurs when

power is turned on or after the exit of a

simulation mode.

Improper communication with sorter

Cause Improper connection or broken wire of

connector or harness between copier and

sorter

Sorter control PWB defective

Control PWB (PCU) defective

Malfunction due to noise

Check

and

remedy

Clear by turning the power supply OFF/ON.

Check communication line connector and

harness.

Replace sorter control PWB or PCU PWB.

F1 02 Content Sorter transport motor error

Detail Transport motor drive trouble

Cause Motor lock

Check

and

remedy

Check transport motor operation with

SIM3-3.

F1 03 Content Sorter guide bar rocking motor trouble

Detail Sorter guide bar rocking motor drive error

Cause Motor lock

Motor speed error

Overcurrent to motor

Sorter control PWB defective

Check

and

remedy

Check guide bar motor operation with

SIM3-10.

F1 04 Content Sorter indexer lower limit detected

Detail Indexer has exceeded lower limit.

Cause Sensor defective

Sorter control PWB defective

Check

and

remedy

Check sensor with SIM3-2.

F1 05 Content Sorter indexer upper limit detected

Detail Indexer has exceeded upper limit

Cause Sensor defective

Sorter control PWB defective

Check

and

remedy

Check sensor with SIM3-2.

F1 06 Content Sorter bin shift motor error

Detail 1) Bin shift is not completed within 2.5

seconds after bin shift request

Cause Motor lock

Improper motor speed

Overcurrent to motor

Sorter control PWB defective

Check

and

remedy

Check bin shift motor operation with

SIM3-4.

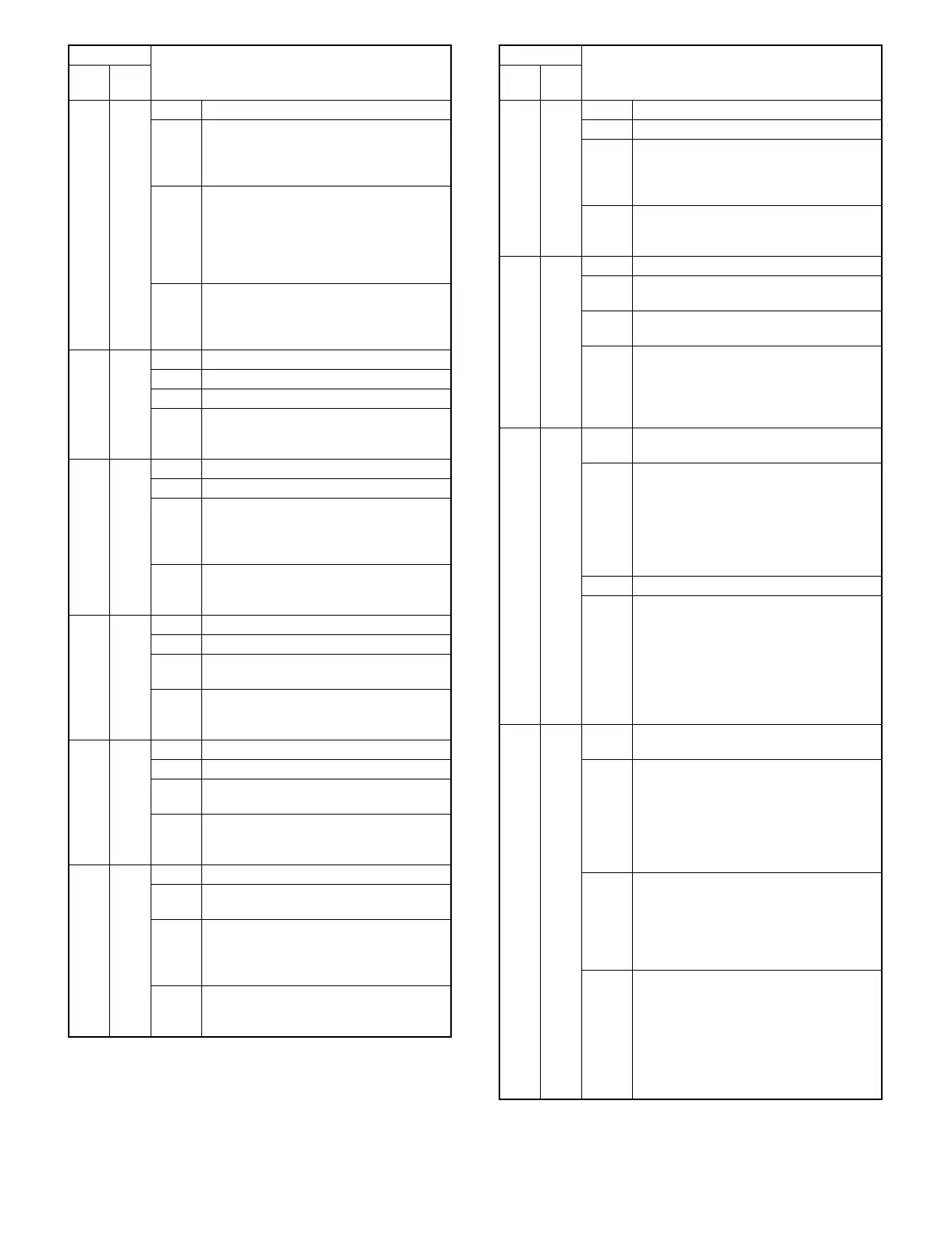

Trouble code

Description

Main

code

Sub

code

F1 08 Content Sorter staple shift motor trouble

Detail Staple motor drive trouble

Cause Motor lock

Motor speed error

Overcurrent to motor

Sorter control PWB defective

Check

and

remedy

Check staple motor operation with SIM3-8.

F2 02 Content Toner motor connector disconnected

Detail Connection detection signal with toner

motor is OFF

Cause Connector harness defective

Connector disconnected

Check

and

remedy

Check toner motor connector for

connection.

Check connector harness to main PWB for

connection.

Check harness for broken wire.

F2 31 Content Process control trouble (OPC base surface

reflection factor is improper)

Detail Usually the sensor gain is adjusted so that

the output is a certain value, by reading

the drum base surface with the image

density sensor before starting process

control.

However, a certain output is not obtained

by adjusting the sensor gain.

Cause Image density sensor defective

Check

and

remedy

Check process control sensor output with

SIM44-03. (Do not adjust)

If the result is far different from the

specified value, it suggests the sensor is

defective. Check the sensor and harness.

If the deviation is relatively small, check

the sensor and drum surface for

contamination.

F2 32 Content Process control trouble (drum marking

sensor defective)

Detail Usually the sensor gain is adjusted so that

the output is a certain value, by reading

the drum base surface with the drum

marking sensor before starting process

control.

However, a certain output is not obtained

by adjusting the sensor gain.

Cause Drum marking sensor defective

Improper connection of harness between

PCU PWB and drum marking sensor

Drum marking sensor contaminated

OPC drum cleaning improper

Charging voltage improper

Check

and

remedy

Check process control output with

SIM44-02. (Do not adjust.)

If the result is far different from the

specified value, it suggests the sensor is

defective. Check the sensor and harness.

If the deviation is relatively small, check

the sensor and drum surface for

contamination.

9 – 94

Loading...

Loading...