9

9-1 9-2

CX51N3/N4

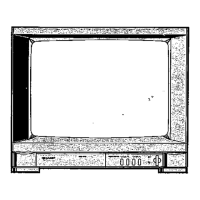

1. Receive the "PAL Color Bar" signal.

2. Press R/C to set Picture Normal condition.

3. Connect the oscilloscope to

Red cathode(D882 Chathode).

» Range : 20 V/div. (AC) (Using 10:1 probe)

» Sweep time : 10 µsec/div.

4. Using the R/C call "SUB COL" in SERVICE

mode. Adjust SUB COLOUR bus data, so that

the 75% White & Red portions of PAL Color

Bar be at the same level shown as Fig. 1-1.

* Before adjust SUB-COL, make sure COL-

OP=8, COL-O3=4, COL-O4=4. After adjust

SUB-COL,set COL-OP=14, COL-O3=10,

COL-O4=10.

5. Clear the SERVICE mode.

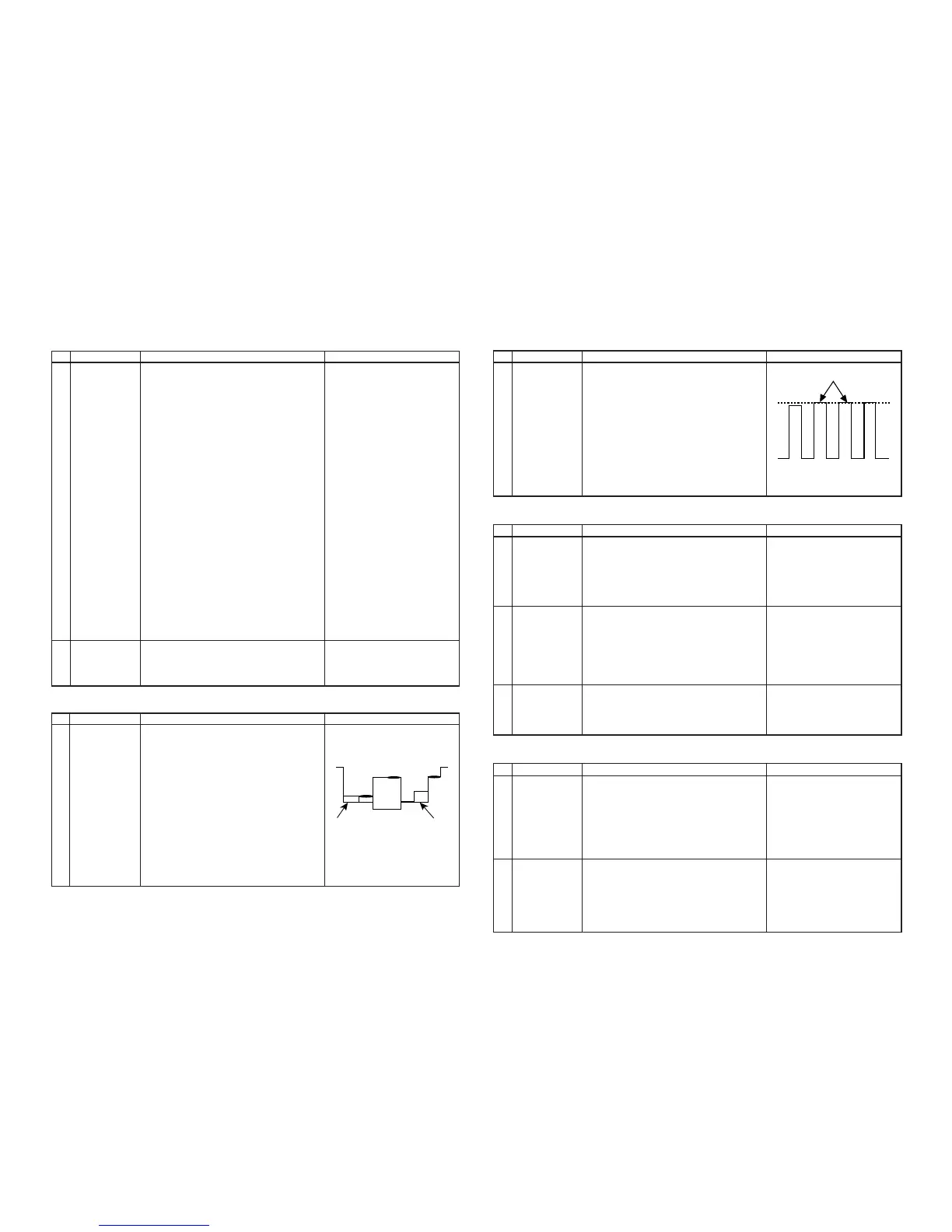

HORIZONTAL AND VERTICAL DEFLECTION LOOP ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1

2

3

4

5

6

V-SLOPE (I

2

C

BUS CON-

TROL)

V-SHIFT-50

(I

2

C BUS

CONTROL)

V-AMP50

(I

2

C BUS

CONTROL)

H-SHIFT (50)

(H-CENTER)

S-CORREC-

TION (I

2

C BUS

CONTROL)

SUB-

SHARPNESS

1. Receive Monoscope Pattern Signal.

2. Call the "V-LIN" mode.

3. Increase or decrease "V-LIN" by Volume key

till the horizontal line in the center of

monoscope is just at the position where the

blanking starts.

1. Call the "V-CENT" mode.

2. Increase or decrease "V-CENT" by Volume key

till the picture is centered.

1. Call the "V-AMP" mode.

2. Increase or decrease "V - AMP" by Volume

key to set overscan of 9.5% typical.

Adjustment Spec 9.5% range +1% -0%.

1. Call the "H-CENT" mode.

2. Increase or decrease "H-CENT" by Volume key

to center the picture horizontal.

1. SET DATA TO 20

* Check the E-5 CH Monoscope Pattern then re-

adjust V-Slope, V-Shift and V-Amp to makesure

adjustment is in acceptable Ring-Shaped.

1. SET DATA TO 20

PAL CHROMA ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1 SUB COLOUR

(I

2

C BUS

CONTROL)

1 Focus 1. Receive the "Monoscope Pattern" signal.

2. Press R/C to set Picture NORMAL condition.

3. Adjust the focus control to get the best focus-

ing.

Fig. 1-1

NTSC CHROMA ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1 SUB-TINT

(I

2

C BUS

CONTROL)

1. Receive the "NTSC3.58 Colour Bar" signal thru

AV in.

2. Connect the oscilloscope to TP47B (P882 pin

5) BLUE-OUT.

»

Range : 100mV/div. (AC) (Use Probe 10:1)

»

Sweep time: 10 µsec/div.

3. Call the "SUB-TINT" mode in service mode.

Adjust the "SUB-TINT" bus data to obtain the

waveform shown as Fig. 1-1.

4. Clear the SERVICE mode.

PROTECTOR OPERATION CHECKING

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1 BEAM

PROTECTOR

1. Receive "Monoscope Pattern" signal.

2. Set CONTRAST MAX.

3. Set BRIGHT MAX.

4. During the Collector & Emitter of Q883/5/7

short, make sure the protector ON and switch

to standby mode.

* Select one of Q883/5/7 to do

each short test.

2H.V

PROTECTOR

1. Receive "Monoscope Pattern" signal.

2. Connect output of Bias Box to D603 cathode

(R610 side).

3. Set voltage of Bias Box to 18V and make sure

the protector is not work.

4. Set voltage of Bias Box to 27V, and make sure

the protector is work.

A/V INPUT AND OUTPUT CHECKING

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1

VIDEO AND

AUDIO OUT-

PUT CHECK

1. Receive the "PAL Color Bar" signal (100%

White Color Bar, Sound 400 Hz 100% Mod).

2. Terminate the Video output with a 75 ohm im-

pedance. Make sure the output is as specified

(1.0 Vp-p ±3 dB).

3. Terminate the Audio output with a 10k ohm im-

pedance. Make sure the O/P is as specified

(1.76 Vp-p ±3 dB).

2 VIDEO AND

AUDIO INPUT

CHECK

1. Using the TV/AV key on the remote controller,

make sure that the modes change in order of

TV, AV & TV again and the video & audio out-

put are according to the input terminal for each

mode.If connect input to Front and Rear AV

terminal, input terminal of Front AV will be se-

lected.

3 Other

protectors

1. Once finish rectified Electrolytic Capacitor short

testing in +B line, check all possible damaged

components on +B line.

(Use random selected set for inspection)

Fig. 1-1

W

Y

Cy G Mg R

B

SAME LEVEL

Cy

G

B

W

Y 100%W

75%

Mg R

Loading...

Loading...