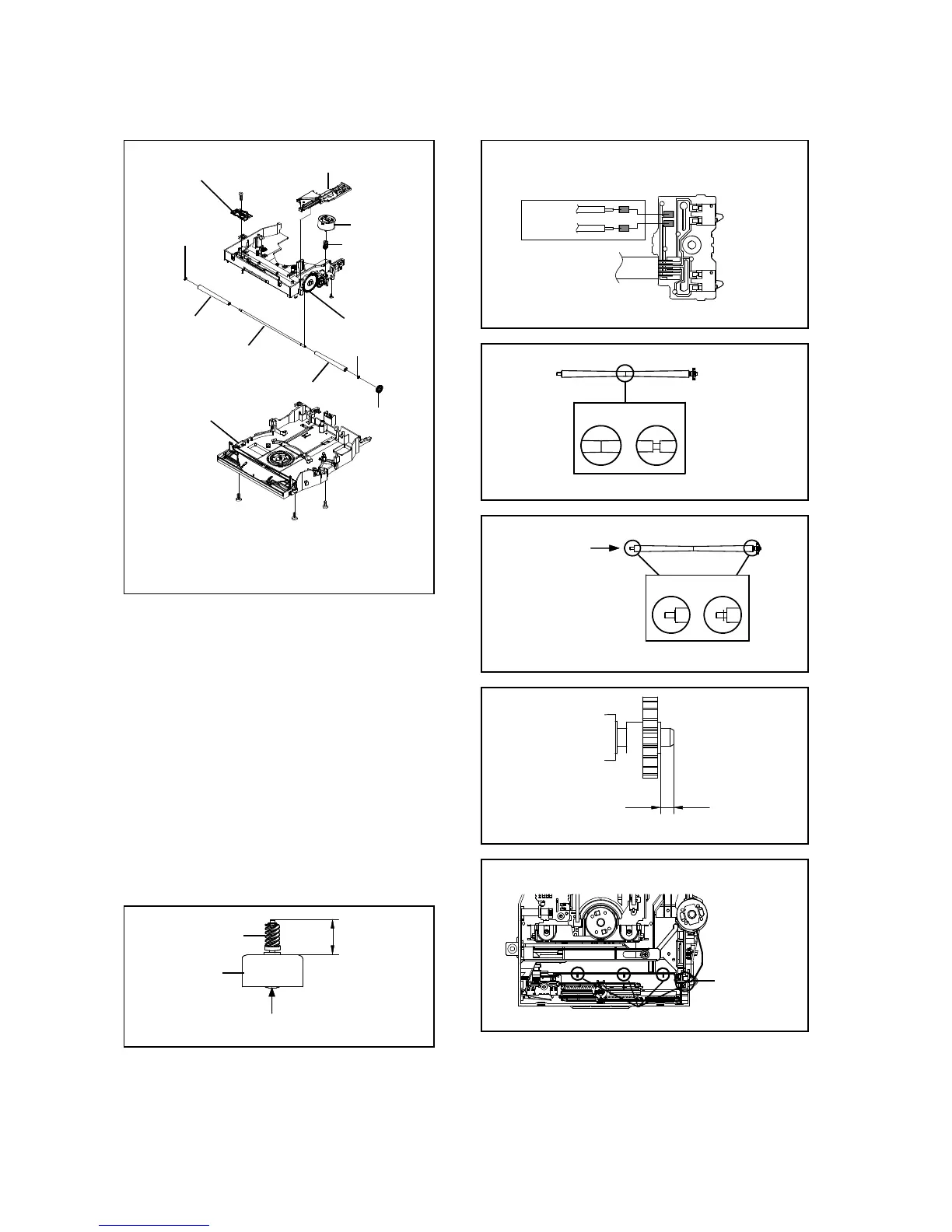

• Screw Torque: 1.0 ± 0.3kgf•cm (Screw (3))

(OK) (NG)

NOTE

1. In case of the Gear Worm installation, check if the value

of the Fig. 2-3-C is correct.

2. When installing the wire of the Loading Motor PCB Ass'y,

install it correctly as Fig. 2-3-D.

Manual soldering conditions

• Solderin

erature: 350 ± 5

o

C

• Soldering time: Within 4 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

3. In case of the Roller Cone installation, install correctly as

Fig. 2-3-E.

4. In case of the Lumirror Washer installation,

install correctly as Fig. 2-3-F.

1.8 + 0, - 0.1mm

5. In case of the Gear Roller installation, check if the value

of the Fig. 2-3-G is correct.

6. After the assembly of the Loader Sub Ass'y, hook the wire

on the Loader Sub Ass'y as shown Fig. 2-3-H.

14.3 + 0, - 0.1mm

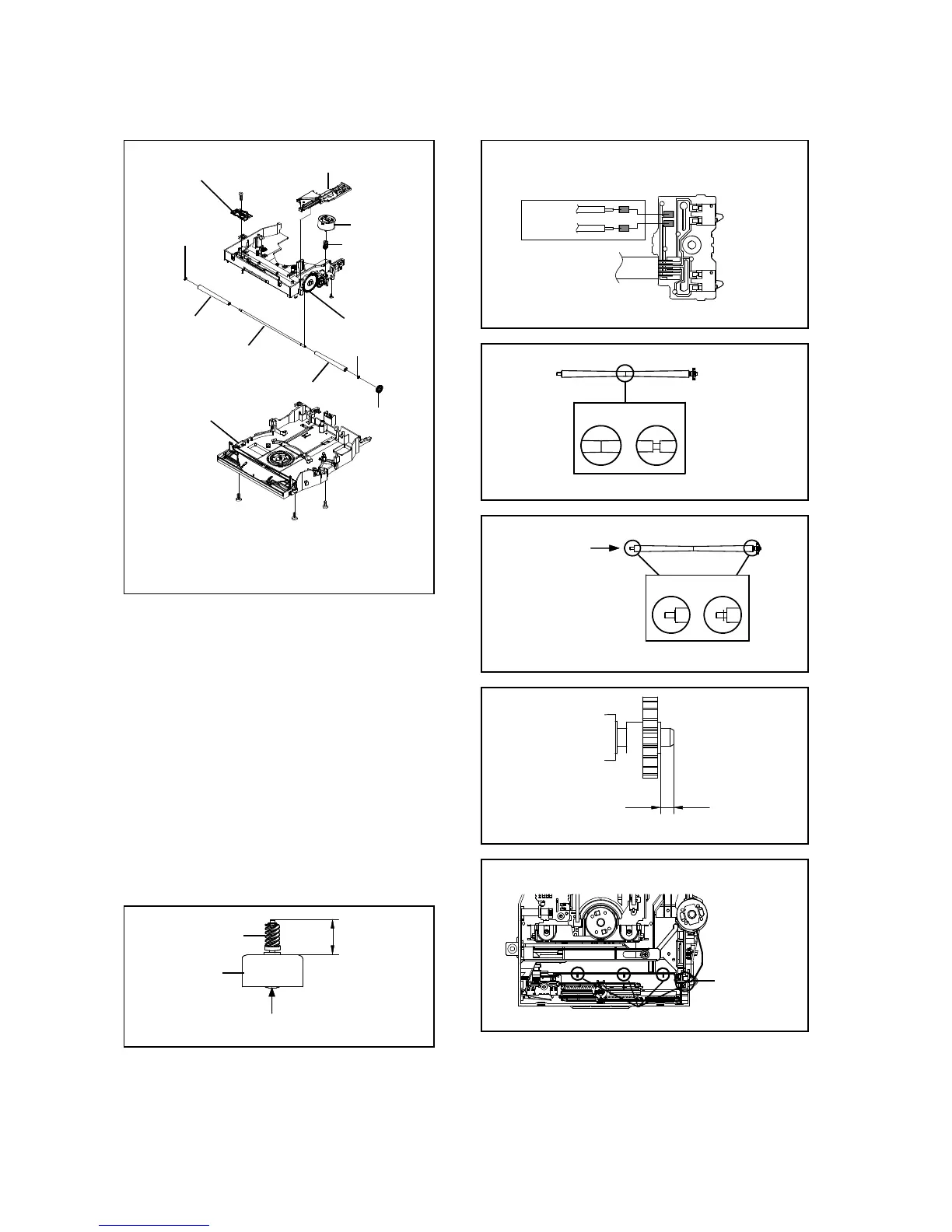

Loader Sub Ass'y

Fig. 2-3-B

Gear Worm

Loading Motor

Safety surface for pressing of the insert.

Fig. 2-3-C

Fig. 2-3-G

Roller Sub Ass'y

Fig. 2-3-F

Fig. 2-3-H

Check Hook

Check Hook

Safety surface for

pressing of the insert.

B2-3

Loading...

Loading...