SECTION 7 GAS PURGE

36

263-13236

7

The turbo molecular pump incorporates a gas purge port (Fig. 2-1 (2)). Gas purging is not

required for ordinary evacuation. However, a purge gas flow is recommended to protect the

bearings during evacuation of large quantities of corrosive gas during an etching process, for

example. An inert and chemically stable non-condensing gas is most suitable for the purge gas.

Nitrogen is the most popular purge gas. A purge gas flowrate between 20 and 30 mL/min is

appropriate.

Please consult your shimadzu representative, during evacuation of corrosive gas.

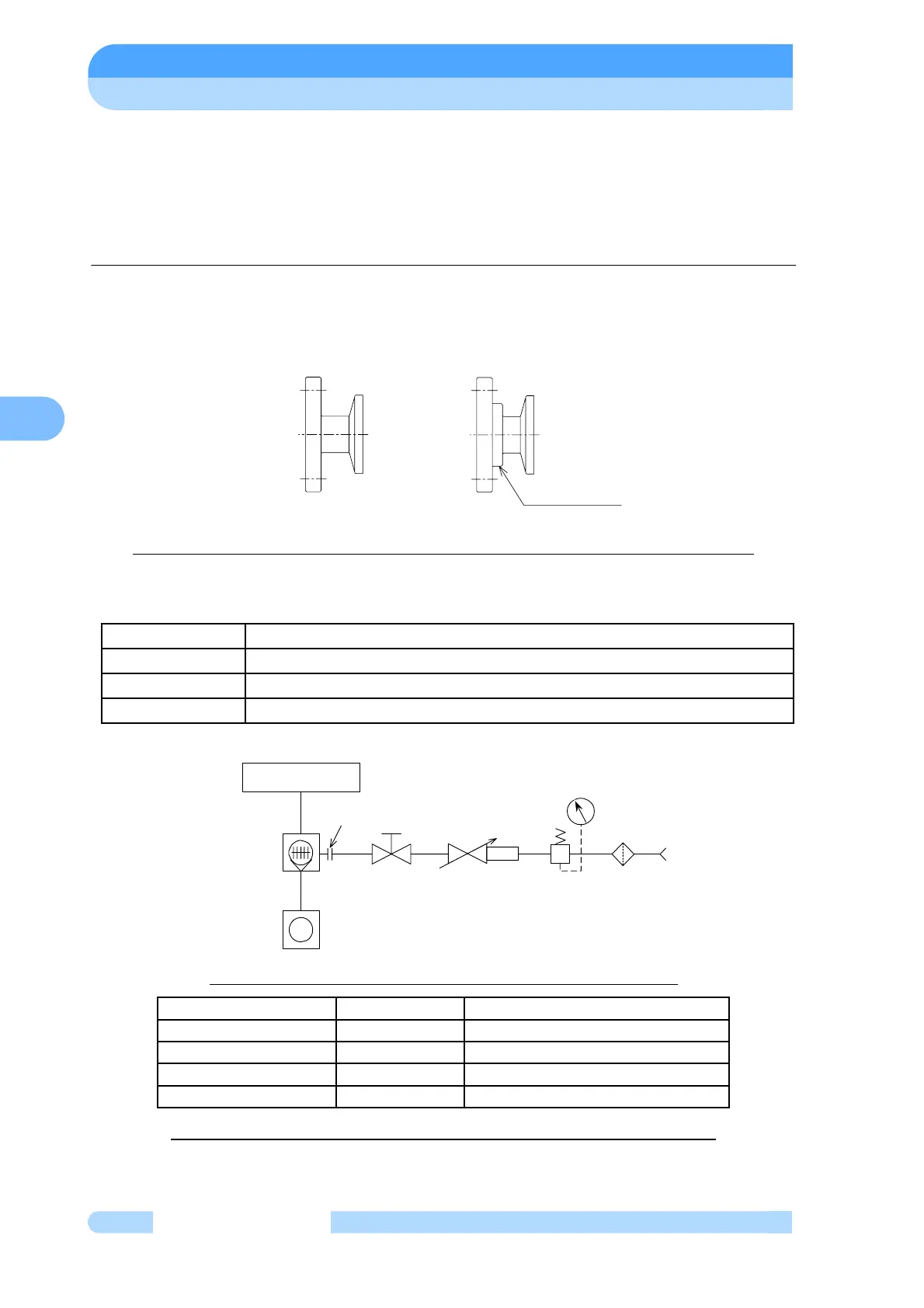

The gas-purge adaptor is available without an orifice (recommended) or with an orifice (option).

Refer to Fig. 7-1 to check whether the gas-purge adaptor attached to the purchased pump

incorporates an orifice. Connect the gas-purge adaptor correctly, according to the piping

diagrams below. The diagram shows the KF10 joint, but the method of recognizing the orifice is

the same for all joints.

Without orifice

With orifice

Fig. 7-1 How to Recognize if the Gas-purge Adaptor Incorporates an Orifice

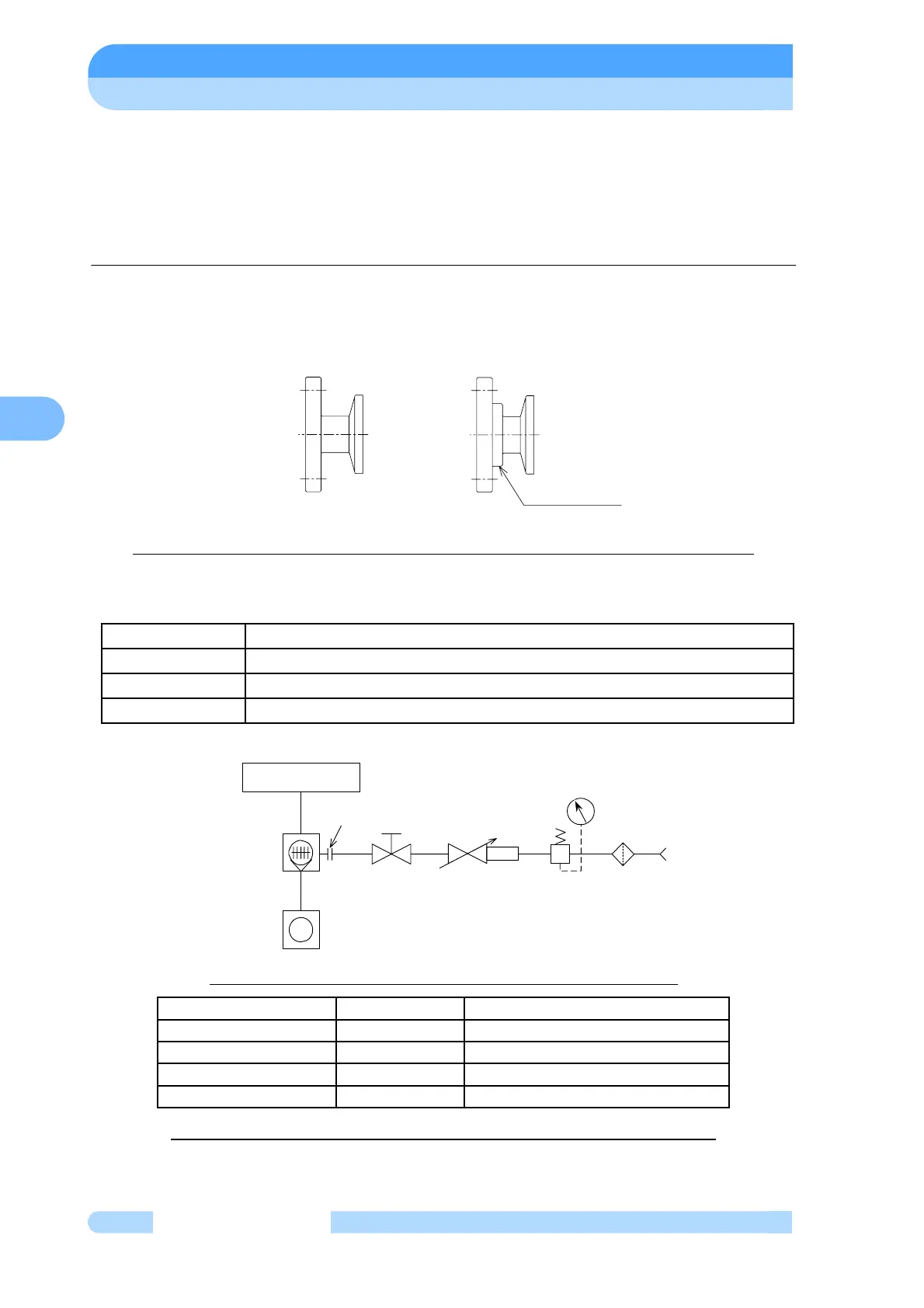

Fig. 7-2 shows an example of a gas-purge piping diagram. Use a filter element size of 5 μm,

or less. Use a stop valve to start and stop the purge gas flow.

Fig. 7-2 Gas Purge Method (diameter of orifice is φ0.5mm)

Table. 7-1 Table of Gas-purge Ports (diameter of orifice is φ0.5mm)

Gas supply

20

± 10 kPa gauge pressure (nitrogen gas)

Gas feed start After starting backing vacuum pump; before evacuating process gas

Gas feed stop

After exhausting process gas sufficiently; before stopping backing vacuum

Type of gas Nitrogen gas or argon gas (Purity > 99.99%)

Joint PART No. Description

KF10 262-77592-19 GP ADAPTOR, 0.5 KF10

UJR 6.35 263-14770 GP ADAPTOR, 0.5 UJR

SWAGELOK

φ6.35

263-14771 GP ADAPTOR, 0.5 SWG

4-VCR 263-14772 GP ADAPTOR, 0.5 VCR

Orifice insertion

position

PURGE PORT

CONTROL VALVE

VACUUM CHAMBER

TURBO MOLECULAR

PUMP

BACKING VACUUM PUMP

FILTER

VALVE

REGULATOR

GAS

SOURCE

FLOWMETER WITH

Loading...

Loading...