Mark V 520 Summary Manual

SM - 13

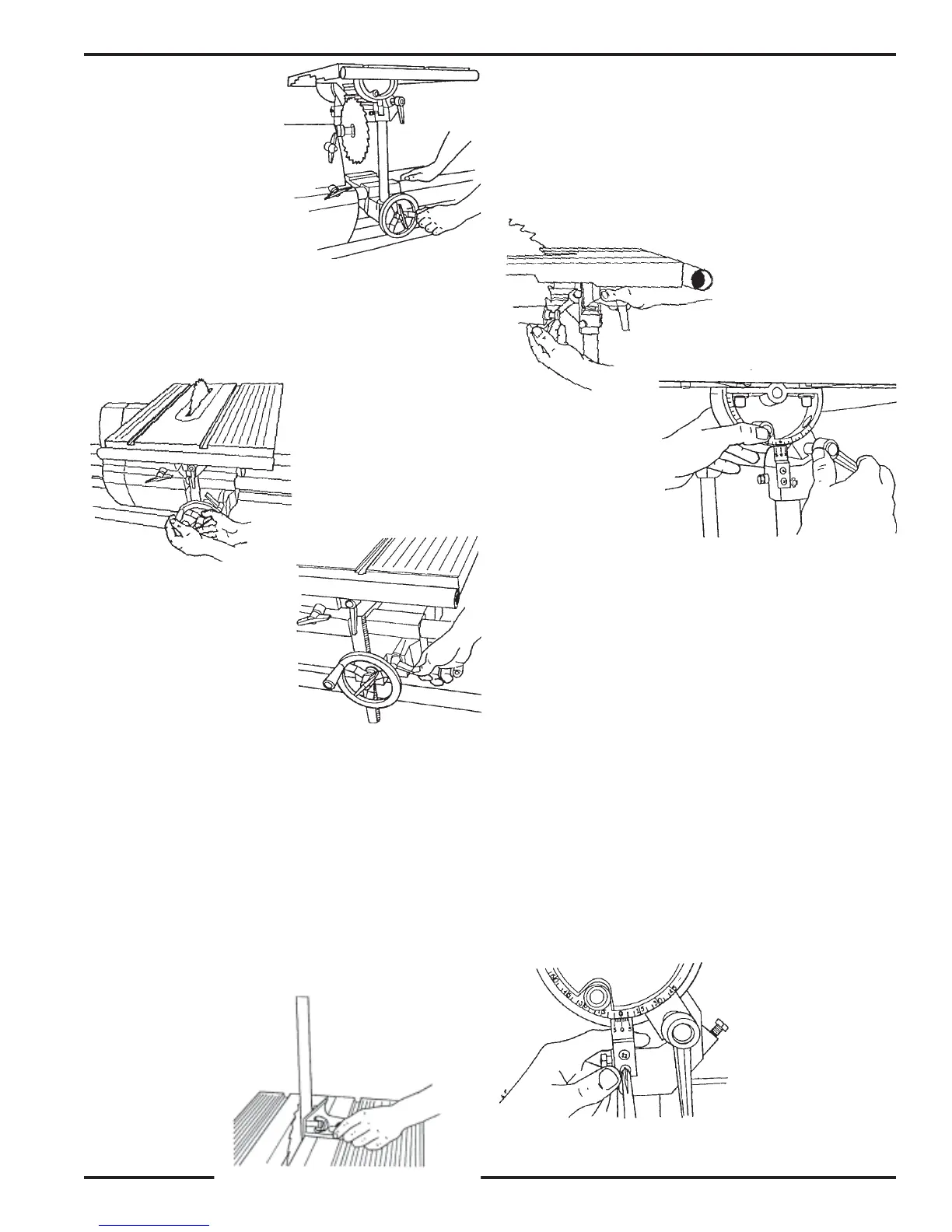

24. Lower the worktable (but not all the way

down) so the saw blade comes through the

slot. Lock the table height, as seen in Figure B-

62.

25. Tighten the carriage lock, as shown in Figure

B-63.

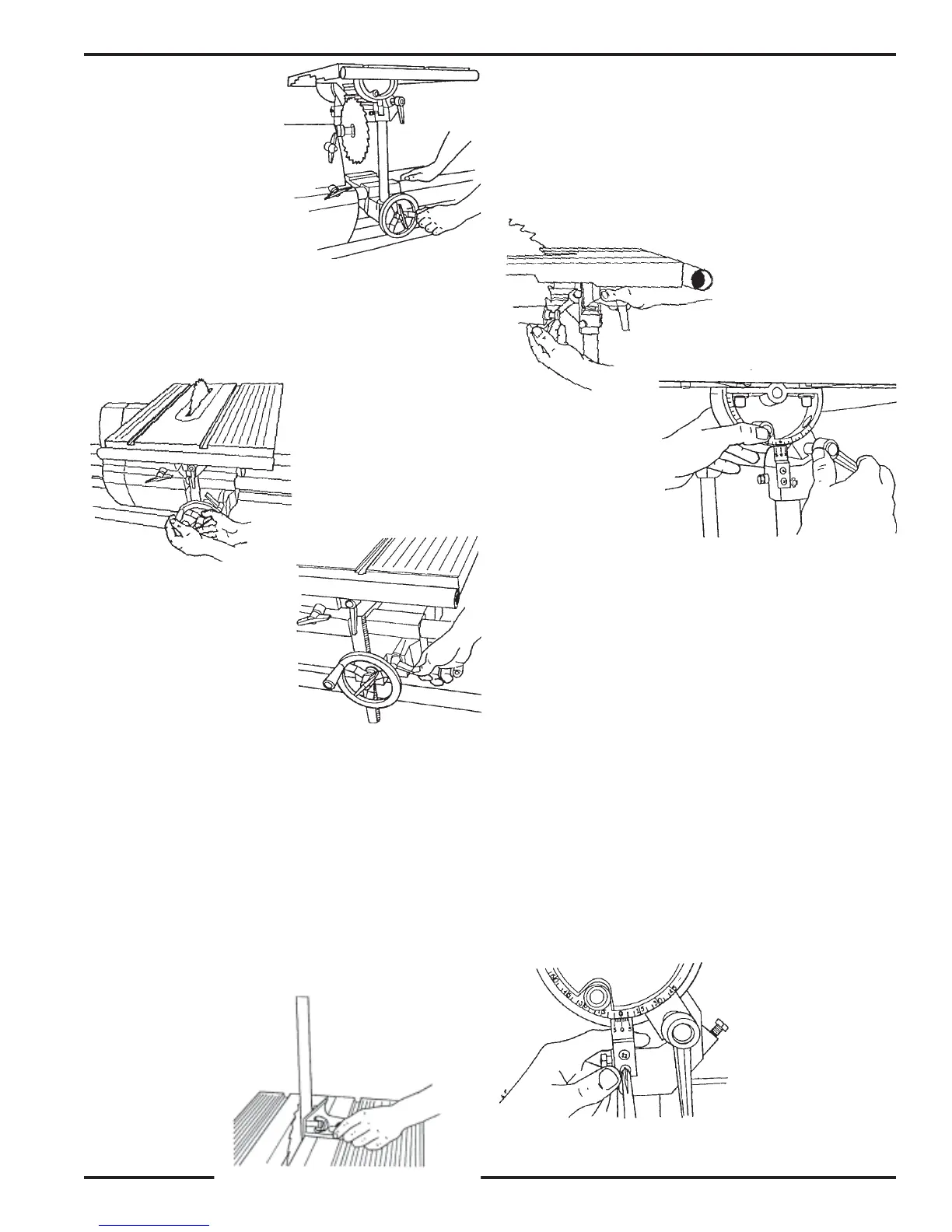

26. Place the combination square against both the

saw blade and worktable, as seen in Figure B-

64. Make sure the square's blade does not

touch a saw tooth and does rest in a gullet

between teeth.

27. If the worktable is not exactly perpendicular

to the saw blade, adjust the worktable so it is

perpendicular to the saw blade, then tighten

the tilt lock.

28. To adjust the 0° stop, simultaneously depress

the table stop pin and use a 1/2" wrench to

adjust the stop bolt. The stop bolt should just

contact the side of the stop pin. Once the stop

bolt is adjusted, the stop pin will "lock" back

when the tilt lock is tightened. See Figure B-

65.

Figure B-61

Figure B-62

Figure B-63

Figure B-66

Figure B-65

Figure B-67

Figure B-64

29. Loosen the tilt lock, move the worktable, then

depress the 0° stop pin until the stop bolt

contacts it. Tighten the tilt lock, and recheck

the setting by repeating Steps 26 through 28.

See Figure B-66. (It is very important to re-

check the setting!)

ADJUST THE TABLE TILT INDICATOR

30. Tighten the table tilt lock and check that the

"0" mark on the indicator aligns with the "0"

mark on the trunnion.

31. To adjust the scale, use a medium Phillips

screwdriver to loosen the two screws which

hold the indicator to the tie bar. See Figure B-

67. Then while holding the indicator in posi-

tion so the "0"s are aligned, retighten the

screws.

Loading...

Loading...