SM - 22

Summary Manual Mark V Model 520

2. Mount the sandpaper on the sanding disc. If

you are mounting sandpaper for the first

time, clean the disc with denatured alcohol

and a clean rag to remove the protective oil.

Otherwise the sandpaper will not stick. Press

the sandpaper firmly on the disc and smooth

it from the center toward the edge.

NOTE

To remove worn-out paper, peel it off the disc.

Then clean the disc with denatured alcohol. To

make it easier to remove the sandpaper, heat the

sanding disc in an oven at a maximum temperature

of 150° (in a convential oven).

3. Position the headstock so that you can reach

the main spindle.

4. Mount the lower saw guard on the main

spindle and open it up by loosening the

cover lock knobs and sliding the cover to the

right. Tighten the guard lock knob.

5. Mount the sanding disc all the way onto the

main spindle. Tighten the setscrew against

the flat of the spindle. Move the guard cover

towards the disc until it is 1" away. Tighten

the two knobs.

6. Position the table 1/16" away from the disc

1/2" away if you are going to use the quill

feed. Adjust the table height so that the table

surface is slightly above the center of the

disc.

7. Check all locks. The table tilt lock, carriage

lock, table height lock, headstock lock and

quill lock (if not used) should be securely

tightened.

WARNING

Do not attempt to move the headstock when the

machine is in the vertical position; the headstock

could fall on you.

Setting Up

the Vertical Drill Press Mode

1. Turn the speed dial to "Slow", then turn off

and unplug the Mark V.

2. Position the headstock 10" away from the

headrest (right side), and the carriage 20"

away from the base mount. Tighten the

headstock and carriage locks. DO NOT

OVER TIGHTEN.

3. Position the worktable surface just above

the top of the headstock. Tighten the table

height lock. Then loosen the tilt lock and tilt

the table to the left 90°. Tighten the tilt lock.

4. Mount the drill chuck all the way onto the

main spindle. Tighten the setscrew against

the flat of the spindle.

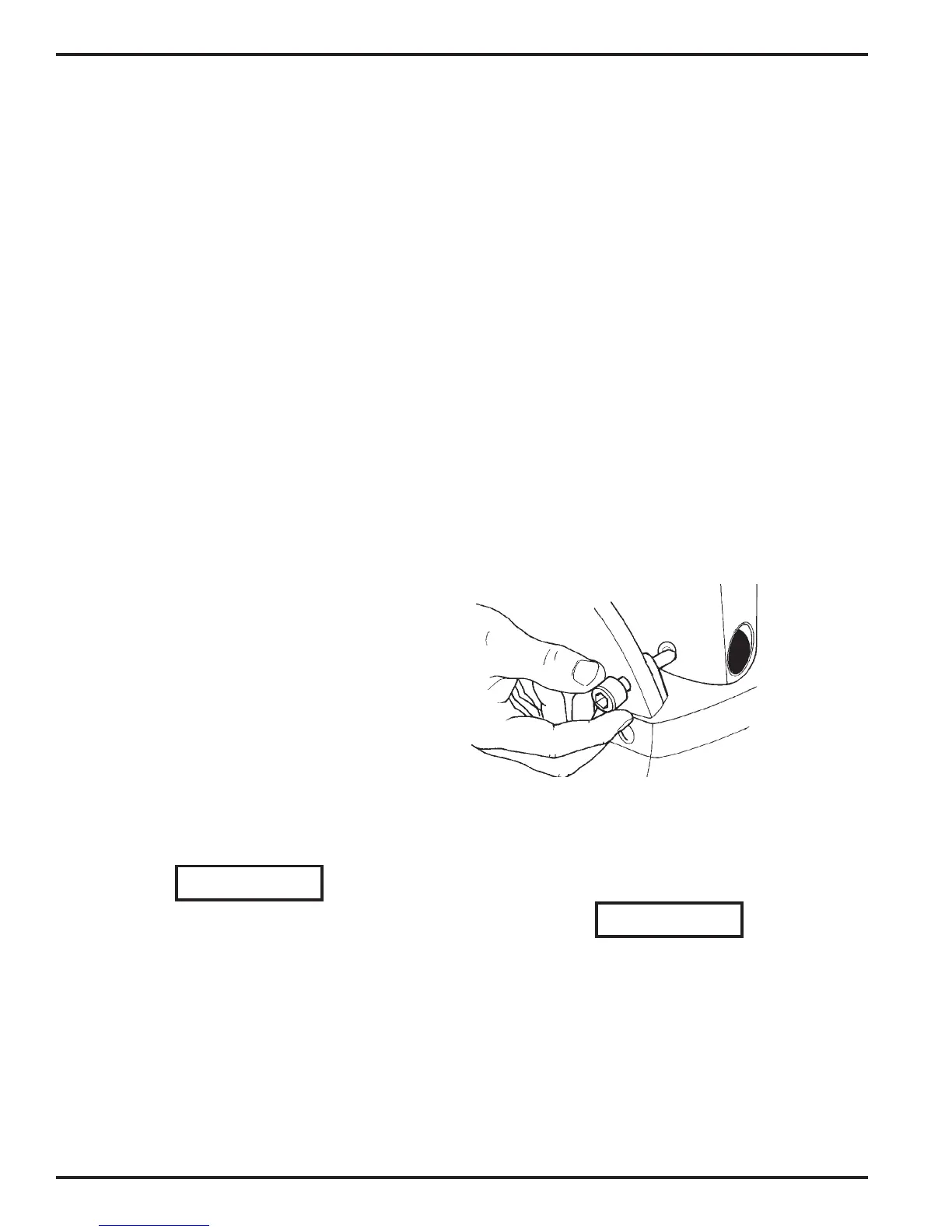

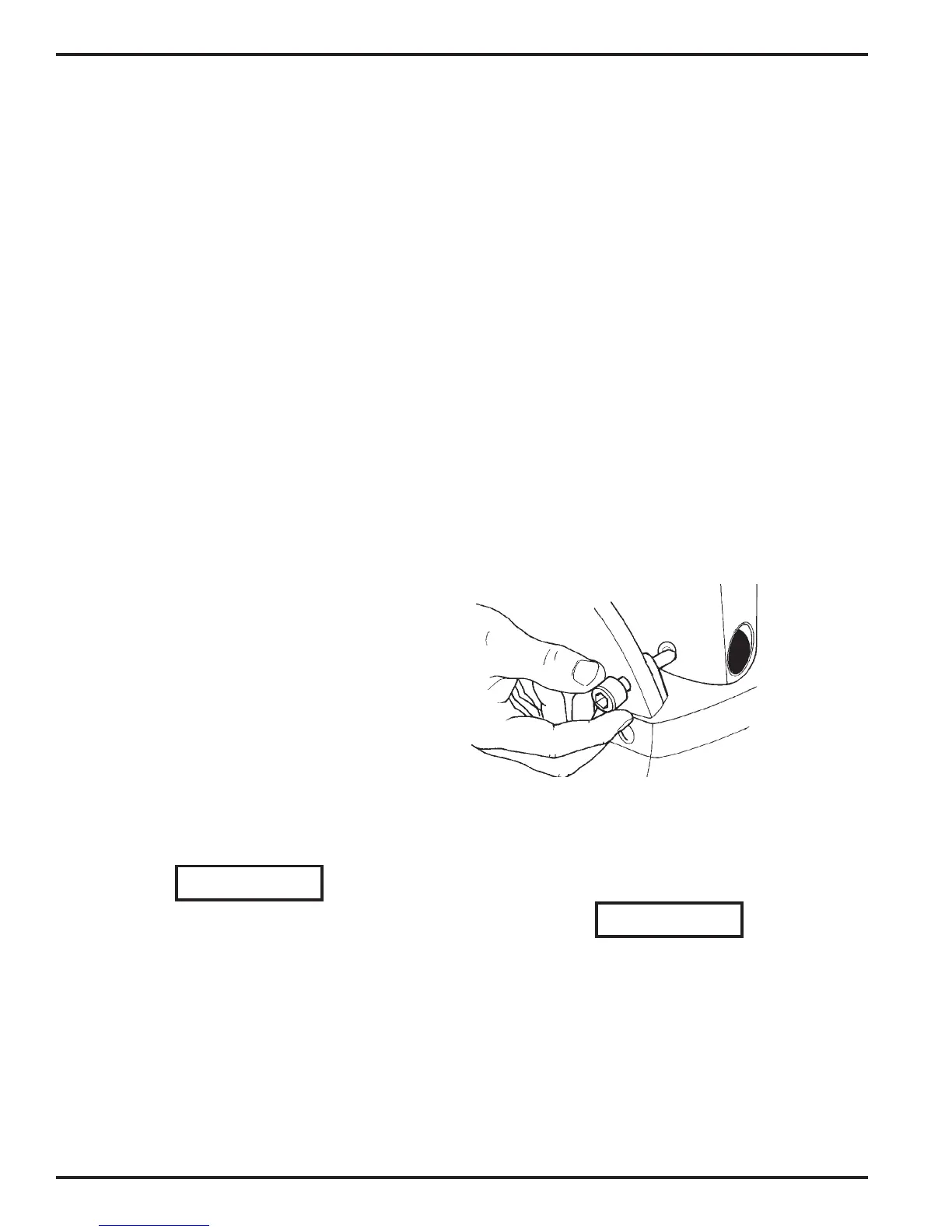

5. Loosen the headrest lock. Grasp the way

tubes with both hands, one hand to the left

of the headstock and the other to the right,

then raise the machine into the vertical po-

sition. Tighten the base lock, rock the way

tubes side-to-side. Retighten if possible.

This helps to take the play out of the base

pivot and keeps the Mark V from wobbling.

NOTE

The base lock does not fit dead center in the hole,

but off to one side, as shown in Figure B-131.

Figure B-131

6. Move the quill feed handle to the back of the

headstock if you desire.

7. Mount a drill bit in the chuck and tighten

with the chuck key.

WARNING

Never leave the key in the chuck. Remove the key

immediately after securing the bit.

Also, do not attempt to move the headstock when

the machine is in the vertical position; the head-

stock could fall on you.

8. Check all locks. The table tilt, carriage, table

height, headstock and quill (if not used)

locks should be secure.

Loading...

Loading...