SM - 20

Summary Manual Mark V Model 520

The Mark V Model converts to five modes– table

saw, disc sander, drill press, horizontal boring,

and lathe.

NOTE

These Mode Setup procedures assume that there is

nothing mounted to any spindle and all alignments

and adjustments have been completed.

One of the most useful features about the Mark V

is that you can "borrow" angles and setups from

one mode to the other. This greatly improves the

accuracy of your woodworking.

To "borrow" a setup, don't break down the ma-

chine completely as you change from mode to

mode. For example, if you need to cut a miter,

sand it smooth, and then bore for dowels, keep

the table and the miter gauge in the same position

as you move from table sawing to disc sanding to

horizontal boring. This will ensure that your

stock is cut, sanded, and bored precisely the

same. It also saves you setup time.

As you change from one mode to another, keep

these four safety rules in mind:

1. Turn the speed dial to "Slow," then turn off

and unplug the Mark V before you break

down one mode and set up another. Al-

ways have the speed dial set to "Slow." It is

dangerous for both you and your electrical

circuit to start accessories at high speed (i.e.,

the sanding disc can blow fuses at table saw

speed and the lather will throw stock at

rout-shape speed).

2. Make sure that accessories are properly

mounted on the main spindle. The flat on

the main spindle is ground with a "reverse

taper" to keep accessories secured.

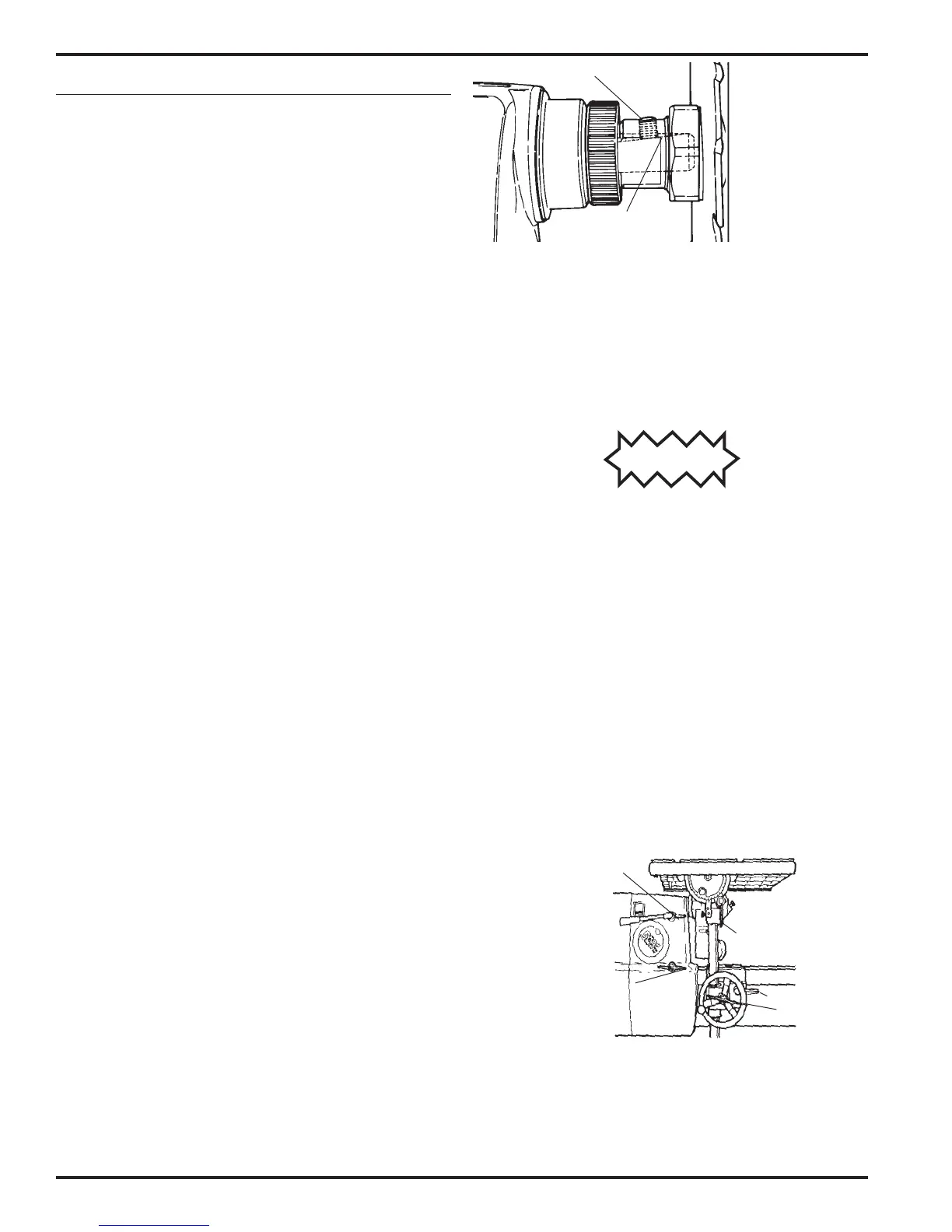

a. To properly mount an accessory,

push it onto the main spindle all the way.

Then use a 5/32" Allen wrench to tighten the

setscrew against the flat of the spindle. (See

Figure B-119.) To make sure the accessory is

securely mounted, rock the accessory back

and forth slightly as you tighten the set-

Figure B-119

Mode Setups

screw and then again after it is tight, while

keeping the spindle from turning. If the

accessory seems to loosen, tighten the set-

screw again until you've removed any "play."

3. Check all locks before turning on the ma-

chine. To properly secure a lock, spin it until

it stops, then tighten it an extra 1/4 turn.

CAUTION

Be careful not to overtighten locks. Overtightening

locks may damage the way tubes, table support tubes,

or other parts of the machine.

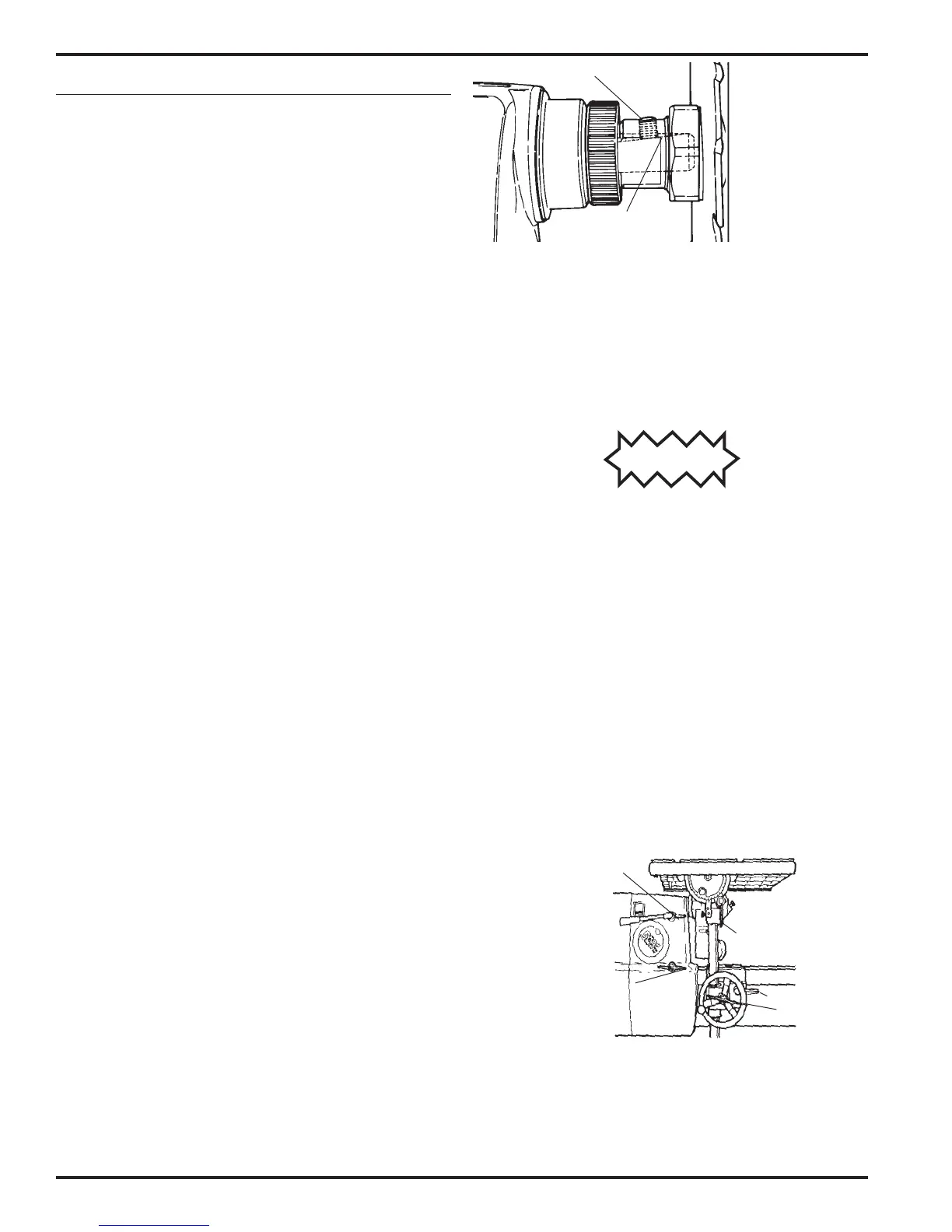

To be sure all locks are as they should be, make a

five-point check before you turn on the Mark V.

With a clockwise sweep of your hand, check each

of these locks in succession: table tilt lock, car-

riage lock, table height lock, headstock lock, and

quill lock. See Figure B-120. The carriage lock

handle must be secured in the horizontal posi-

tion. The quill lock should be loose in the drilling

and boring modes, and for some sanding opera-

tions. In the lathe mode, this procedure becomes

a four-point check, since the table has been re-

moved.

Reverse

taper

Set-

screw

Carriage

Lock

Table height

Quill lock

Head-

stock

Table tilt lock

Figure B-120

When changing from a horizontal to a vertical

position, secure the base lock. When changing

from vertical to horizontal, secure the headrest

lock. If you're mounting accessories in the power

mount or base mount, secure the mount locks.

Loading...

Loading...