8015922/1CC9/2021-07-12 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com CDF600-2200 | SICK 3

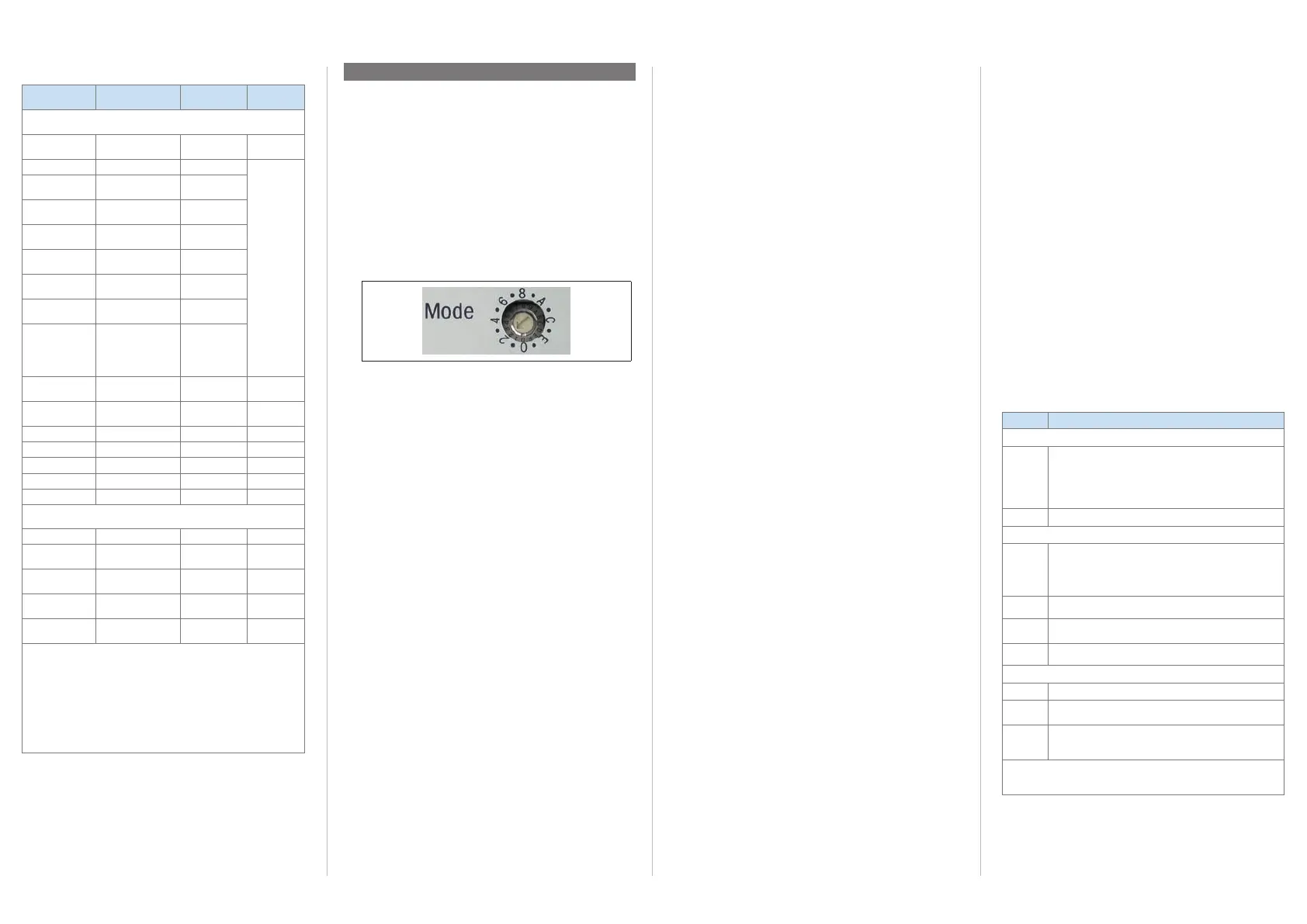

"Mode" rotary encoding switch (hexadecimal-coded)

Operating mode and communication mode for ID sensor to

be connected.

Position Operating mode/Functions

Proxy mode for ID sensor that supports proxy mode

0 Operation with ID sensor that supports proxy mode.

CDF600 communication mode.

(factory default).

Parameter cloning for ID sensor.

Conguration with parameterization modules of GSDML

le possible via IO controller.

1 Reserved for future use.

Gateway mode for ID sensor that supports gateway mode

2 Operation with ID sensor that supports gateway mode.

The eldbus module operates as a gateway.

CDF600 communication mode.

Data transmission rate between ID sensor and eldbus

module: 57.6 kBd.

3 Reserved for future use.

4 As position 2, but data transmission rate between

ID sensor and eldbus module: 9.6 kBd

5 Reserved for future use.

Additional functions

6 ... D

Reserved for future use

E

Operation for rmware update

1)

of eldbus module.

No communication with PROFINET IO.

F Transparent operation

2)

of the eldbus module for

rmware update of ID sensor.

No communication with PROFINET IO.

1) All LEDs ash simultaneously.

2) Data transmission rate 57.6 kBd.

"POWER" LED ashes cyclically 3 times.

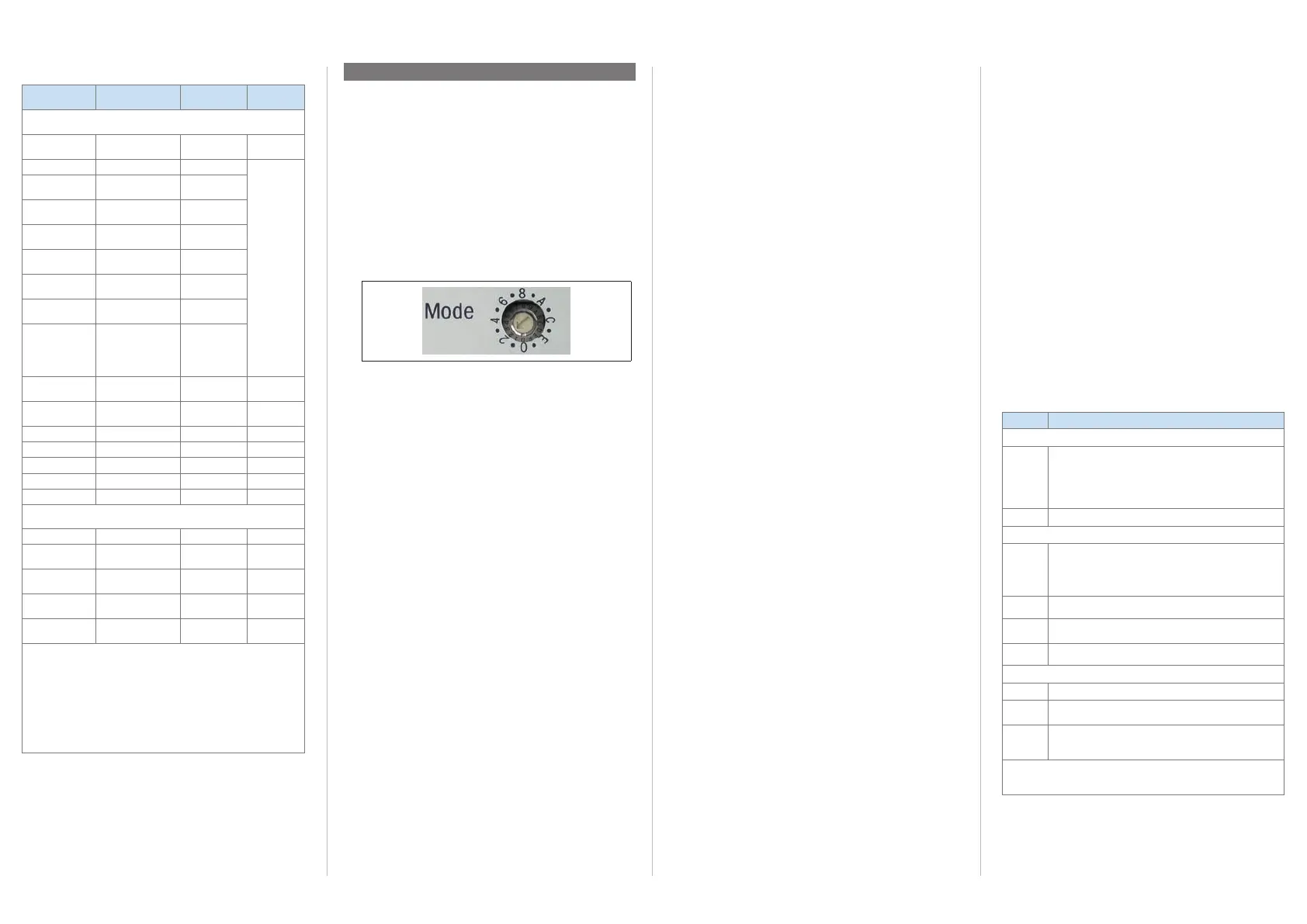

CDF600-2200-relevant specications of ID sensors

ID sensor Supply

voltage

Power con-

sumption

1)

Firmware

version

ID sensors that support proxy mode

CLV61x FIELD-

BUS

DC 10 V ... 30 V 2.8 W, typical V. 1.21

CLV62x DC 10 V ... 30 V Max. 4.5 W V. 5.26

CLV63x

line/raster

DC 18 V ... 30 V 5 W typical

CLV63x

Line with SwSP

DC 18 V ... 30 V 6 W typical

CLV64x

line/raster

DC 18 V ... 30 V 5 W typical

CLV64x

Line with SwSP

DC 18 V ... 30 V 6.5 W typical

CLV65x

line

DC 18 V ... 30 V 8.5 W typical

CLV65x

Line with SwSP

DC 18 V ... 30 V 9.5 W typical

CLV63x ... 65x,

for heating

in addition

2)

DC 24 V ±10% Electronics

type-specic,

see above,

heating

max 30 W

CLV69x

3)

line

DC 18 V ... 30 V 15 W typical On request

CLV69x

3)

Line with SwSP

DC 18 V ... 30 V 17 W typical On request

Lector

®

620 DC 10 V ... 30 V 3 W typical On request

RFH62x DC 10 V ... 30 V Max. 5 W V. 3.10

RFH63x DC 10 V ... 30 V Max. 8 W V. 3.10

RFU62x DC 10 V ... 30 V

4)

8 W, typical

5)

V. 1.50

RFU63x DC 18 V ... 30 V < 20 W, typical V. 1.50

ID sensors that support gateway mode

Lector

®

64x/65x DC 24 V ± 20% 20 W typical –

IDM160 Transducer

DC 24 V/5 V

1.15 W typical –

IDM161 Transducer

DC 24 V/5 V

0.9 W typical –

IDM260 Transducer

DC 24 V/5 V

1.68 W typical –

IDM261 Transducer

DC 24 V/5 V

1.65 W typical –

1) Switching output without load

Power consumption of the eldbus module additionally < 5 W.

2) Connection diagram see & CDF600-22xx Fieldbus Module Technical Informa-

tion

(no. 8015924).

3) Without

conguration option via conguration module in the GSDML le.

4) DC 20 V to 30 V when using the RFU62x-101xx in ambient temperatures

of -20°C to -40°C.

5) Additionally max. 12 W from -20°C to -40°C.

Line with SwSP = Line scanner with oscillating mirror

Other ID sensors on request.

Step 3: Conguration

a. Overview of the conguration process

1. Set operating mode of the eldbus module using the

"Mode" rotary encoding switch.

2. Integrate the eldbus module in the IO controller.

3. Congure data communication in the eldbus.

4. Only ID sensor that supports proxy mode:

Use the SOPAS ET conguration software to set the

remaining functions of the eldbus module.

b. Setting the operating mode in the eldbus module

1. Open the side cover by unscrewing the two screws (ß)

( see “Device layout”, page 4). You can now access

the "Mode" rotary encoding switch.

Set the operating mode with the rotary encoding switch.

Position 0:

Fieldbus module operates as a proxy for an ID sensor

(e.g., bar code scanners from the CLV6xx product family).

Position 2 and 4:

Fieldbus module operates as a gateway for an ID sensor

that supports gateway mode (e.g., hand-held scanner);

data transmission rate dependent on switch setting.

List of modes that can be congured see ”””Mode”

rotary encoding switch (hexadecimal-coded)”, page 3.

The new setting is applied on the eldbus module when

the supply voltage is switched on.

Changes to the settings of the rotary encoding switch after

the power supply has been switched on are not applied in

data communication initially; however, the "POWER" LED

ashes cyclically 2 times.

To apply a change to the operating mode to the eldbus

module, restart both the eldbus module and the ID sen-

sor. In order to do this, switch off the supply voltage for the

eldbus module and switch it on again.

c. Conguring the eldbus module (resume here for

ID sensor that supports proxy mode)

The SOPAS ET conguration software for SICK identication

sensors is used as standard for the commissioning and fur-

ther conguration of the eldbus module with the ID sensor

that supports proxy mode connected to it.

The conguration of the eldbus module is integrated in the

menu of the respective ID sensor that supports proxy mode.

Installing and starting the conguration software

> Download and install the latest version of the SOPAS ET

conguration software, as well as current device descrip-

tion les (*.sdd), from the online product page for the

software: www.sick.com/SOPAS_ET by following the

instructions provided there.

Connect the PC to the eldbus module and switch on devices

1. Connect the PC (switched-off) as follows:

• Serial version of the ID sensor that supports proxy mode

with xed connecting cable (serial data interfaces only):

Use a data cable (no. 6036106, 2 m) to connect the

USB interface

4 of the eldbus module to the PC

interface (USB).

• Ethernet version of the ID sensor supporting proxy

mode:

Use a data cable (e.g., no. 6034414, 2 m) to connect

the Ethernet interface of the ID sensor to the Ethernet

network of the PC.

2. On the user side, switch on the supply voltage DC 10 V

to 30 V chosen according to the table on the left for the

eldbus module and the connected ID sensor.

Following initialization of the eldbus module and while

attempting to establish communication with the ID sensor,

the green "POWER" LED ashes. Once communication has

been established and the eldbus module is ready for op-

eration, the "POWER" LED lights up steady.

Meaning of LEDs see “Optical status indicators”, page

4.

3. Switch on PC and start conguration software via the

"SOPAS" option. Path: Start > Programs > SICK > SOPAS

ET Engineering Tool > SOPAS.

4. Start communication with the ID sensor with SOPAS ET as

described in the operating instructions for the connected

ID sensor that supports proxy mode. In order to do this,

select the desired communication interface for searching

in the connection wizard.

For the remaining steps in the process of conguring the

connected ID sensor, see & CDF600-22xx Fieldbus

Module Technical Information (no. 8015924).

d. Integrating the ID sensor in the IO controller and

conguring data communication on the eldbus

This section provides a brief overview of the general proce-

dure. This is covered in detail in relation to the ID sensor in

the & CDF600-22xx Fieldbus Module Technical Informa-

tion (no. 8015924).

Important!

The required GSDML les are available on the product site of

the eldbus module online: www.sick.com/CDF600-2.

ID sensor that supports proxy mode:

1. Integrate ID sensor as a new IO device in the IO controller

(e.g., PLC).

For this purpose, transfer the SICK sensor-specic GSDML

le for the corresponding ID sensor to the device descrip-

tion database of the IO controller.

See & CDF600-22xx Fieldbus Module Technical Infor-

mation (no. 8015924).

2. Specify the object trigger source and the output format of

the ID sensor for the eldbus using SOPAS ET.

ID sensor that supports gateway mode:

1. Integrate the eldbus module as a new IO device in the

IO controller master (e.g., PLC).

For this purpose, transfer the SICK-specic GSDML le for

the eldbus module to the device description database of

the IO controller.

2. IDM1xx and IDM2xx hand-held scanner:

Use the conguration codes to congure the hand-held

scanner for the eldbus module.

For more information, see & CDF600-22xx Fieldbus

Module Technical Information (no. 8015924).

3. Any ID sensor with RS-232 interface:

Connect RS-232 interface to pin 2, 3, 5 of the eldbus

module (DEVICE connection).

Set communication parameters to:

- Datastring framing: STX and ETX

- Data format: 8 databits, no parity, 1 stop bit

- Data transmission rate: 9.6 kBd or 57.6 kBd according

to the selected position, 4 or 2, of the "Mode" rotary

encoding switch.

Loading...

Loading...