Do you have a question about the Siemens QP Series and is the answer not in the manual?

QP... pressure switches are used for gas and air pressure supervision on industrial and commercial burner applications.

UL listed for USA and Canada, FM approved, ISO 9001 certified; European approved versions available.

Lists product numbers with corresponding pressure ranges in inches water column and mbar, and execution type.

Specifies the electrical rating for the switches as 10A @ 125 to 250 Vac and 1/3 HP @ 125 to 250 Vac.

Defines the maximum operating pressure for the QP series switches as 6 psi (400 mbar).

Specifies the operating temperature range for the switches from -40°F to 140°F (-40°C to 60°C).

Instructions on how to adjust the pressure cut-off setting using the range dial.

Details on the manual reset procedure for switches with a yellow ring on the reset button.

Switches can be mounted horizontally or vertically; feature a 1/4-inch NPT female pressure connection.

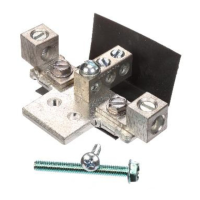

Wiring must be performed by a licensed electrician; illustrates typical wiring for low and high pressure models.

The Siemens QP Series Pressure Switches are designed for the supervision of gas and air pressure in industrial and commercial burner applications. These devices are crucial for ensuring the safe and efficient operation of burner systems by monitoring pressure levels and triggering electrical circuit changes when predefined thresholds are met.

The QP Series comprises two main types of pressure switches: the QPL31 series and the QPH31 series.

The QPL31 series are "low pressure" switches. These devices are configured to break the electrical circuit when the pressure drops below a user-adjusted value. This functionality is vital for applications where a minimum pressure must be maintained for safe operation. For instance, if a gas supply pressure falls too low, the QPL31 switch will open the circuit, shutting down the burner to prevent potential hazards such as flame instability or incomplete combustion. The QPL31 series includes both manual reset and automatic reset models. Manual reset models require an operator to physically reset the switch after a low-pressure event, ensuring that the cause of the pressure drop is investigated before restarting the system. Automatic reset models, on the other hand, will automatically re-engage the circuit once the pressure returns to an acceptable level, which can be useful in applications where brief, transient pressure fluctuations are common and do not pose a significant safety risk.

The QPH31 series are "high pressure" switches. These devices are designed to break the electrical circuit when the pressure increases above a user-adjusted value. This is essential for preventing over-pressure conditions that could damage equipment, lead to leaks, or create dangerous situations. For example, in a system where excessive air pressure could lead to an improper fuel-to-air mixture, a QPH31 switch would interrupt the circuit, stopping the burner until the pressure is brought back within safe limits. Similar to the QPL31 series, the QPH31 series also offers both manual reset and automatic reset models, providing flexibility based on the specific safety and operational requirements of the application.

The QP Series Pressure Switches are designed with several features to facilitate their use and integration into various systems:

While the manual does not explicitly detail maintenance procedures, several aspects of the QP Series design contribute to ease of maintenance and long-term reliability:

| Type | Circuit Breaker |

|---|---|

| Interrupting Rating | 10kA |

| Series | QP |

| Poles | 1 or 2 |

| Standards | UL Listed |

Loading...

Loading...