Programming a Multiple Instance

10-8

STEP 7 Getting Started

A5E00171228-01

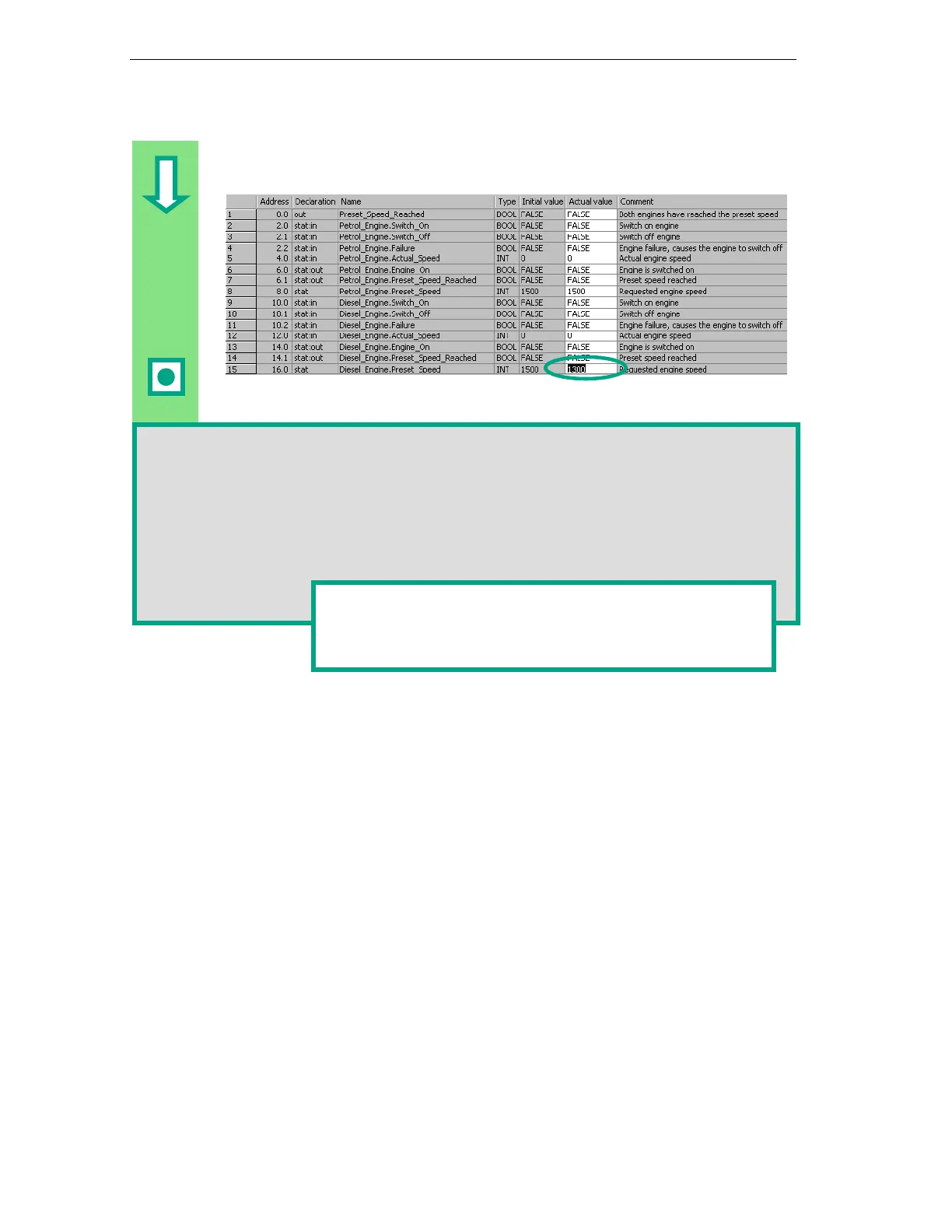

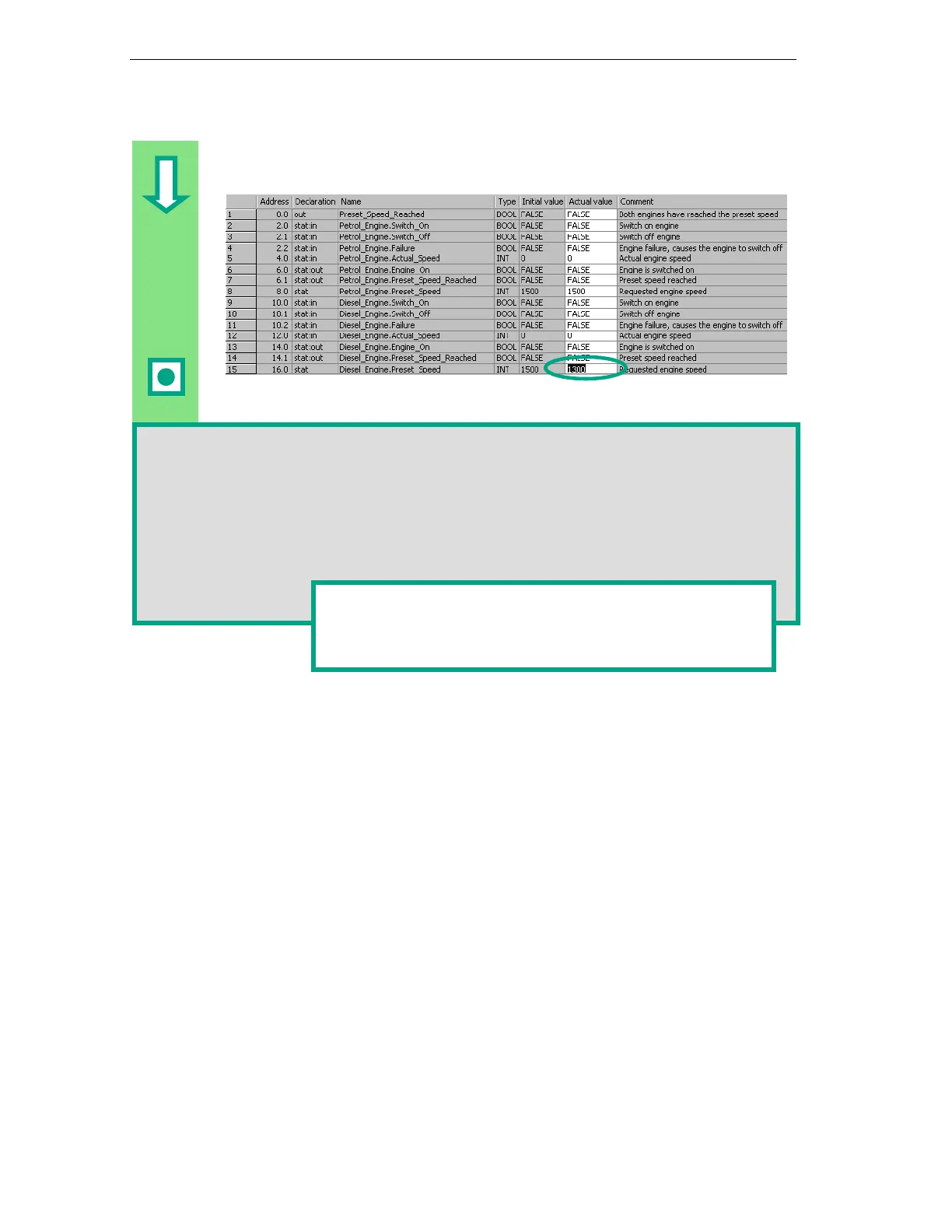

Change the actual value of the diesel engine to "1300," save the block, and then

close it.

All the variables are now contained in the variable declaration table of DB10. In the first half,

you can see the variables for calling the function block "Petrol_Engine" and in the second

half the variables for calling the function block "Diesel_Engine" (see Section 5.5).

The "internal" variables of FB1 retain their symbolic names; for example, "Switch_On." The

name of the local instance is now placed in front of these names; for example,

"Petrol_Engine.Switch_On."

You can find more information under

in the

topics "Programming Blocks" and "Creating Data Blocks."

Loading...

Loading...