Programming a Multiple Instance

10-9

STEP 7 Getting Started

5E00171228-01

10.4 Calling FB10 in OB1

The call for FB10 is made in OB1 in our example. This call represents the same

function which you have learned while programming and calling FB1 in OB1 (see

Section 5.6 onwards.). Using multiple instances, you can replace Networks 4 and

5 programmed from Section 5.6 onwards.

Open OB1 in the project in which you

have just programmed FB10.

Defining Symbolic Names

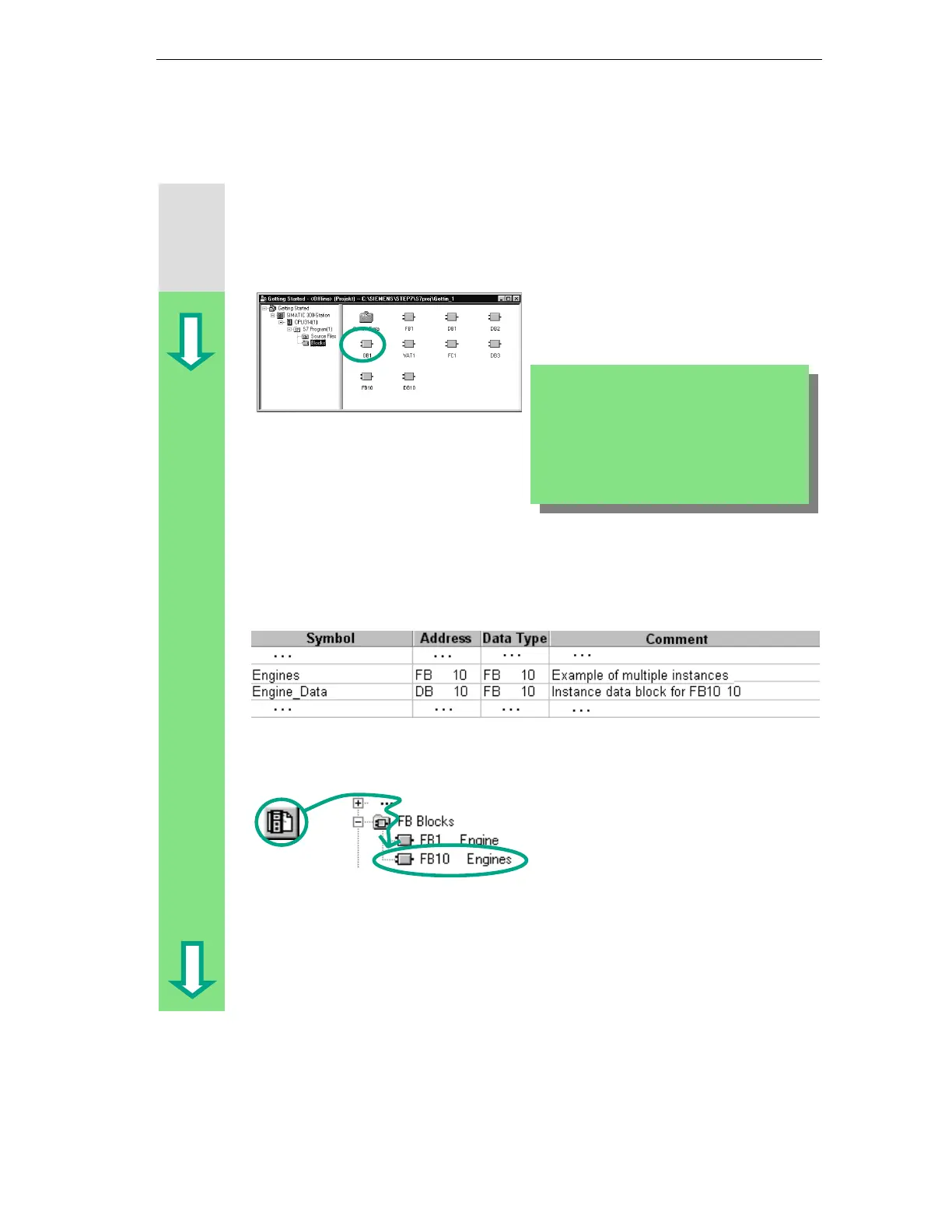

The LAD/STL/FBD program window is open. Open the symbol table using the

menu command Options > Symbol Table and enter the symbolic names for the

function block FB10 and the data block DB10 in the symbol table.

Then save the symbol table and close the window.

Programming the Call in Ladder Logic

Insert a new network at the end of OB1

and add the call for FB10 ("Engines").

If you copied the symbol table from a sample

project (ZEn01_01_STEP7__STL_1-10,

ZEn01_05_STEP7__LAD_1-10 or

ZEn01_03_STEP7__FBD_1-10) to your

"Getting Started" project in Chapter 4, you do

not need to add any symbols now.

Loading...

Loading...