Operating and Programming — Milling Page 100 808D

ISO

Mode

s

Basic Theory

G73 application example program:

M3 S1500 ;spindle rotation

G90 G99 G73 X0 Y0 Z-15 R-10 Q5 F120

;after orientation drill 1st hole, back to R point

Y-50 ;after orientation drill 2nd hole, back to R point

Y-80 ;after orientation drill 3rd hole, back to R point

X10 ;after orientation drill 4th hole, back to R point

Y10 ;after orientation drill 5th hole, back to R point

G98 Y75 ;after orientation drill 6th hole, back to R point

G80 ;cancel fixed cycle

G28 G91 X0 Y0 Z0 ;back to reference point

M5 ;spindle rotation stop

M30

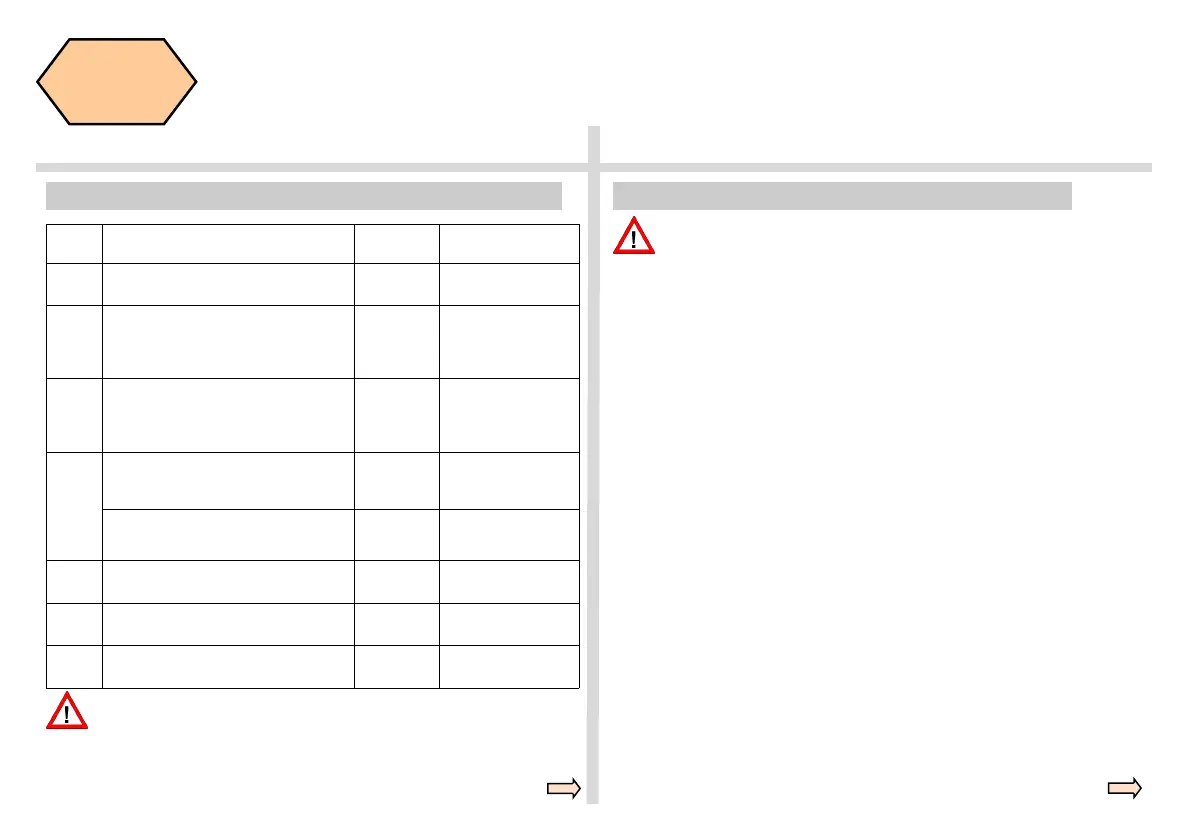

Frequently used letter meanings of typical fixed cycle codes in ISO

P. Descriptions

Unit

Applied range and

note

X/Y

Cutting end point X/Z absolute coordi-

nate values

G73 / G74 / G76

G81 ~ G87 / G89

Z

The distance incremental value be-

tween R point and the bottom of the

hole, or the absolute coordinate value

of the bottom of the hole

G73 / G74 / G76

G81 ~ G87 / G89

R

The distance incremental value be-

tween the start point plane and R

point or the absolute coordinate value

of R point

G73 / G74 / G76

G81 ~ G87 / G89

Q

The depth of every cut

(incremental value)

G73 / G83

Offset value

(incremental value)

G76 / G87

P

The delay time at the bottom of the

hole

ms

G74 / G76 / G89

G81 ~ G87

F

The feedrate of the cutting mm/min G73 / G74 / G76

G81 ~ G87 / G89

K

The repeat times of the fixed cycle

G73 / G74 / G76

G81 ~ G87 / G89

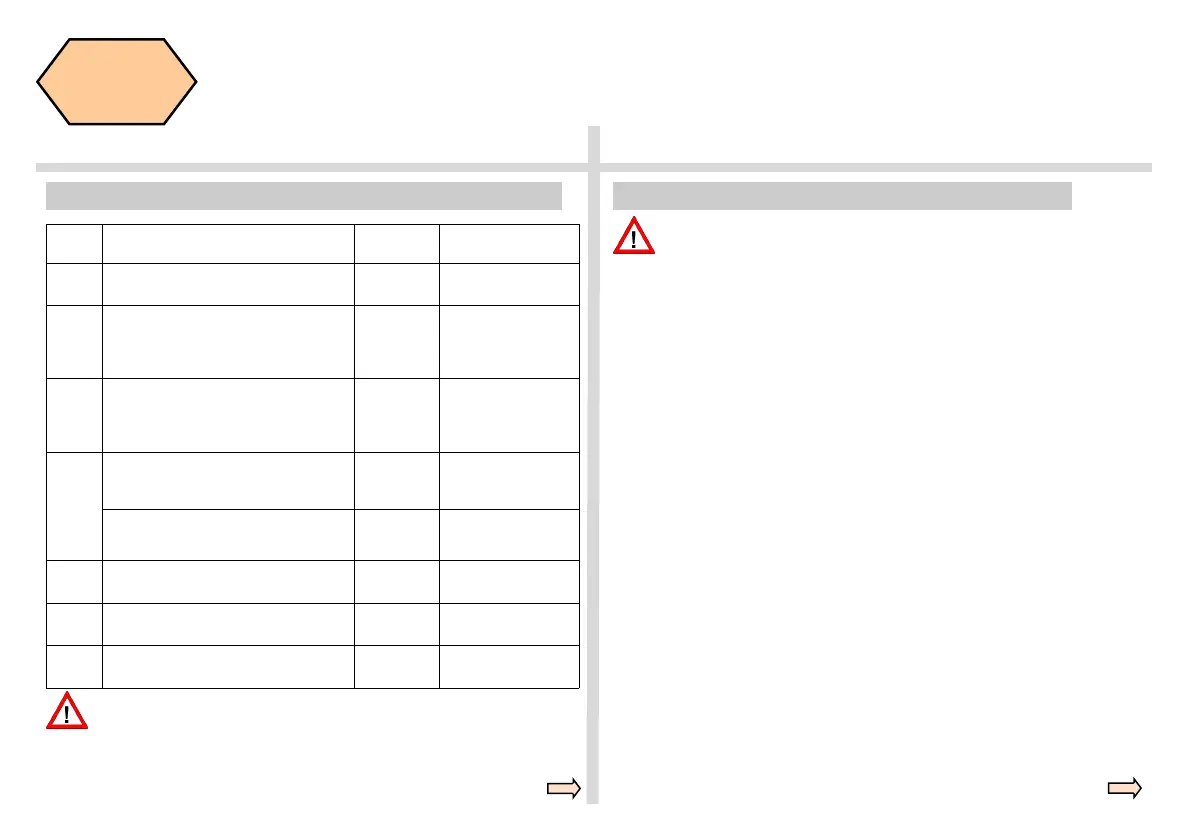

G73 fast-speed deep hole

drilling

Common programming

structures:

G73 X—Y—Z—R—Q—F—

K

Motion process:

① Drilling motion (-Z) →

intermediate feed

② Motion at the bottom of

the hole → none

③ Retraction motion (+Z)

→ fast feed

Brief introduction of typical fixed cycle codes in ISO mode

For the meaning of letters when programming typical fixed

cycles, please refer the figure on the left!

G74 reverse tapping cycle

Common programming

structures:

G74 X—Y—Z—R—P—F—

K

Motion process:

① Drilling motion(-Z) →

cutting feed

② Motion at the bottom of

the hole → spindle rotation

in positive direction

③ Retraction motion(+Z)

→ cutting feed

G74 application example program:

M4 S100 ;spindle rotation

G90 G99

G74 X300 Y-250 Z-150 R-120 P300 F120

;after orientation drill 1st hole, back to R point

Y-550 ;after orientation drill 2nd hole, back to R point

Y-750 ;after orientation drill 3rd hole, back to R

pointX1000 ;after orientation drill 4th hole, back to R pointY-

550 ;after orientation drill 5th hole, back to R pointG98

Y750 ;after orientation drill 6th hole, back to R

pointG80 ;cancel fixed cycle

G28 G91 X0 Y0 Z0 ;back to reference point

M5 ;spindle rotation stop

M30

Note:change the parameter 10884=0,to make X100 → 100 um / X100. →

100 mm

In 808D, the default ISO program feed distance unit is mm!

(X100→100mm)

Loading...

Loading...