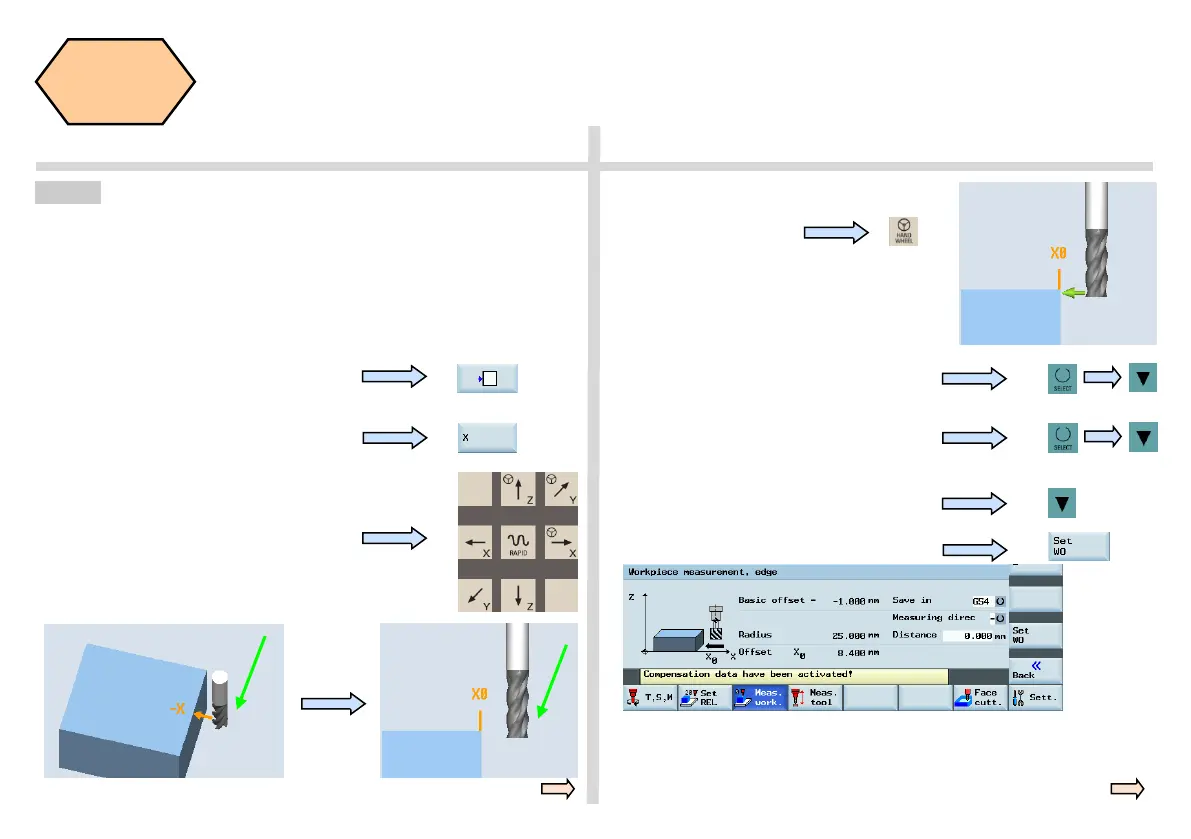

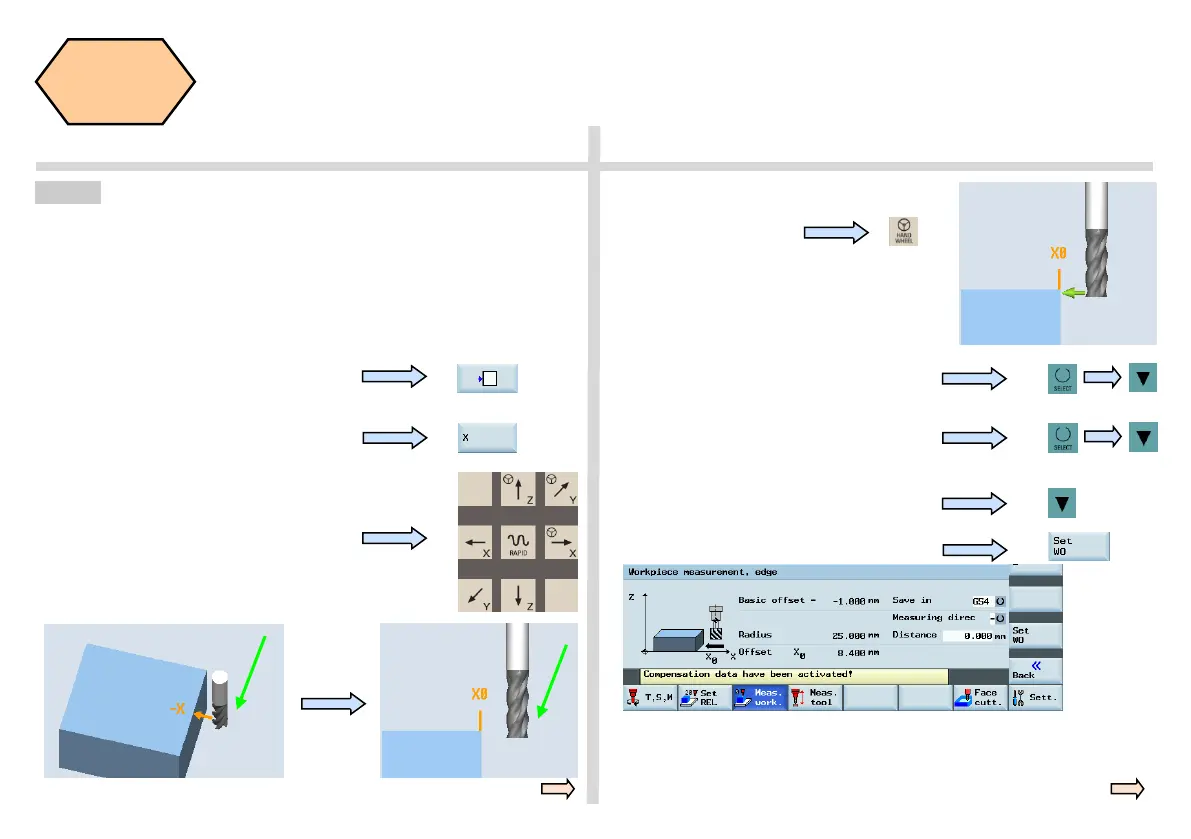

808D Page 25 Operating and Programming — Milling

Workpiece

Setup

s

This method is normally for setting the zero point of the work-

piece at the edge of the workpiece.

Method1

Press the corresponding SK of the first

icon on the right-hand side of the PPU.

Using a tool that has a measured “Tool length & radius”, move the tool to

a known position on the workpiece. Using either JOG or Handwheel,

scratch an edge and then calculate the zero point of the workpiece.

The process of setting the “X” zero point (“X0”) is described below.

Press the appropriate SK to select the

feed axis which needs to be set up.

Press the axis traverse keys to

move the tool to the required set-

ting position in the X axis.

Press the “Handwheel”

key on the MCP to

position the tool at the

X0 edge of the work-

piece.

Set “Distance” as “0”.

Select “Save in” Offset “G54” (or other

offset).

Select “Measuring direction” as “-”.

(This value should be chosen according to

realities)

Press the “Set WO” SK on the PPU.

“Step 2” must be repeated for the setting of Y and Z zero points.

If you change the tool because of wear/damage during the machining

process, you must remeasure the length of the tool.

SEQUENCE

Loading...

Loading...